Endoscope guide wire

A technology of endoscope and guide wire, which is applied in the direction of internal fixator, bone drill guidance, internal bone synthesis, etc. It can solve the problems of easy breakage of guide wire welding, poor propulsion ability, and difficulty in grasping the position of insertion into the body. , to achieve the effect of solving the problem of easy breakage of the welding joint, improving the propulsion ability and good rotation compliance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

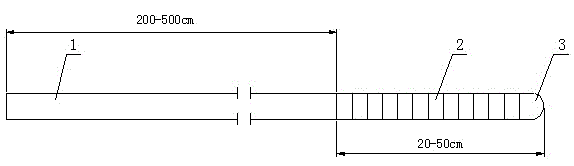

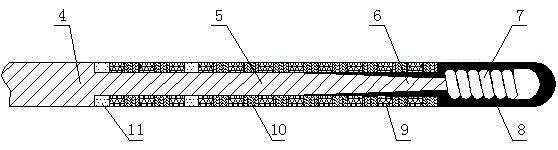

[0039] figure 1 Shown is the invention's 1 In the embodiment of the guide wire, the metal wire material of the metal core wire 1 is made of nickel-titanium alloy. The metal core wire 1 has a base section 4 with a diameter of 0.78mm (300cm in the present embodiment); a middle section 5 with a diameter of 0.65mm extending continuously to the front end (30cm in the present embodiment); The conical section 6 (15cm in the present embodiment) that the front end shrinks continuously. The middle section is colored with yellow and black pigments containing barium sulfate polyurethane resin tubes (the length of each tube is 8mm), which is continuously and alternately covered to form a 20cm-long straight line composed of the first and second direct-viewing sign color rings 9 and 10. View logo section 2. Look directly at the base section 4 ends of the sign portion 2, use 2 polyurethane resin tubes colored by red pigments, sandwich the above-mentioned yellow and black signs, and set...

Embodiment 2

[0041] From the base section 4 of diameter 0.78mm (being 300cm in the present embodiment), make the conical section 6 (being 45cm in the present embodiment) of continuous dwindling to the front end of diameter 0.15mm, with the sulfuric acid containing yellow and black pigment coloring The polyurethane resin tube of barium (each tube length is 8mm), is successively and alternately set on the above-mentioned guide wire, forms the direct-view mark part 2 that is made up of the first and second direct-view mark color rings 9, 10 of 25cm long. At the 4 ends of the base section of the direct-viewing sign part 2, two polyurethane resin tubes colored with red pigments are used to clamp the above-mentioned yellow and black signs, and the interval is 10cm, so that the first, second and third direct-viewing sign color circles The direct vision marking part 2 composed of 9, 10, and 11 can more accurately prompt the position where the guide wire is inserted. A platinum coil is instal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com