Lithium ion battery gel polymer electrolyte, preparation method and application thereof

A technology of lithium-ion batteries and gel polymers, which is applied in secondary batteries, circuits, electrical components, etc., can solve the problems of high cost, low ion conductivity, and difficult industrial production of lithium ions, so as to reduce production costs and prepare The effect of simple process and improved mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

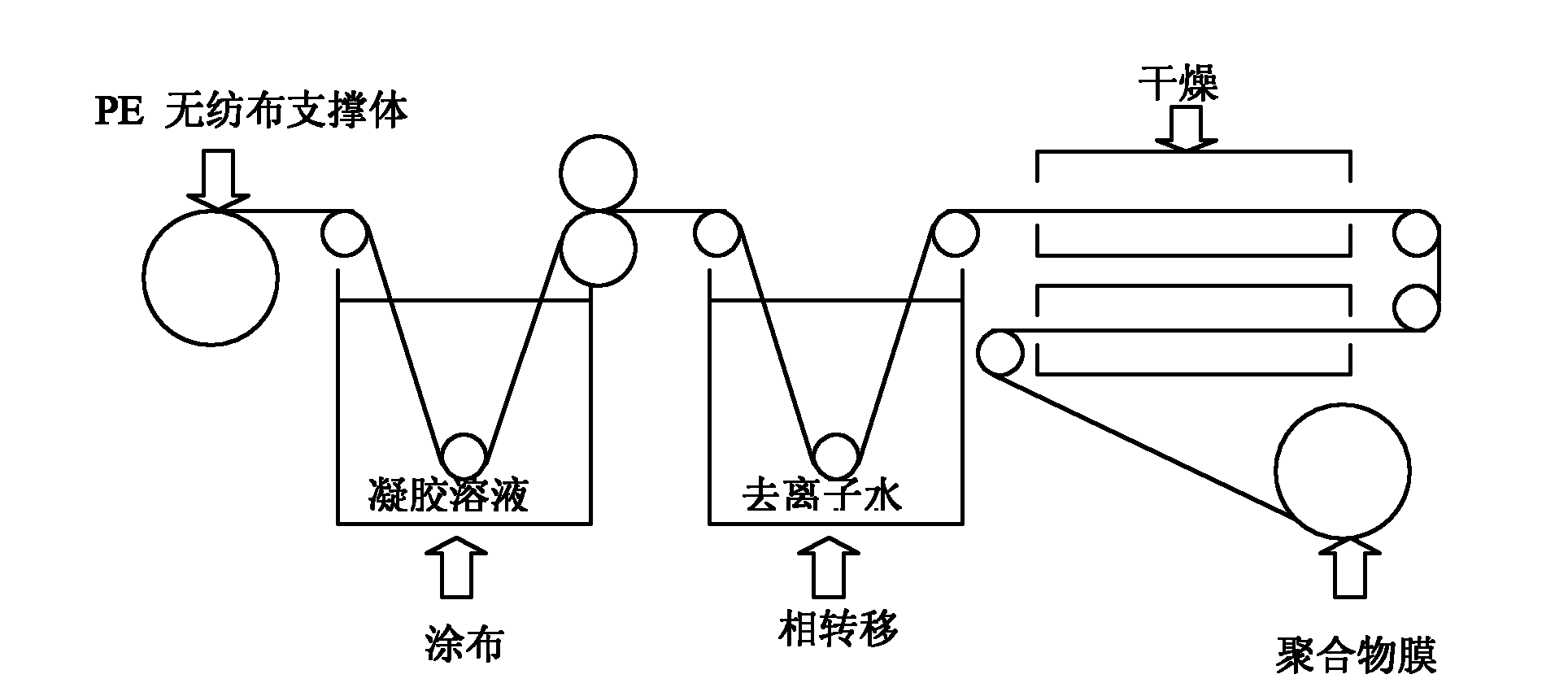

Embodiment 1

[0036]The monomer acrylonitrile (AN) and vinyl acetate (VAc) are mixed according to the molar ratio of 7:3, and the copolymer poly(acrylonitrile-vinyl acetate) is obtained by emulsion polymerization (the polymerization method is the same as that disclosed in Chinese patent CN101353435A) )P(AN-VAc). Dissolve P(AN-VAc) and nanoparticles in the solvent N, N-dimethylformamide at a mass concentration of 2% to obtain a viscous liquid. The addition of nanoparticles is 10% of the polymer mass. After completely dissolving , soak the cheap and easy-to-obtain polyethylene PE non-woven support in the gel liquid, take it out after 20 minutes, and then pass the polymer-coated PE non-woven support film through a large water bath tank filled with deionized water Initiate phase transfer in medium, then dry and remove residual solvent at 100°C to obtain a lithium ion battery gel polymer film supported by a non-woven fabric support, the specific implementation method is as follows figure 1 show...

Embodiment 2

[0038] The monomer acrylonitrile (AN) and vinyl acetate (VAc) were mixed according to the molar ratio of 8:2, and the copolymer poly(acrylonitrile-vinyl acetate) P(AN-VAc) was obtained by emulsion polymerization. P(AN-VAc) and nano-SiO 2 According to the mass concentration of 0.5%, it is dissolved in the solvent acetone to obtain a viscous liquid, nano-SiO 2 The addition amount of the polymer is 5% of the polymer mass. After it is completely dissolved, soak the cheap and easy-to-obtain polyethylene PE non-woven fabric support in the gel liquid, take it out after 10 minutes, and then put the polymer-coated PE non-woven fabric The supported membrane was induced to undergo phase transfer in a large water-bath tank filled with deionized water, followed by drying at 80 °C to remove residual solvent to obtain a lithium-ion battery gel polymer membrane supported by a non-woven support. After the polymer film was cut to an appropriate size, it was placed in a vacuum drying oven at 50...

Embodiment 3

[0040] The monomer acrylonitrile (AN) and vinyl acetate (VAc) were mixed according to the molar ratio of 9:1, and the copolymer poly(acrylonitrile-vinyl acetate) P(AN-VAc) was obtained by emulsion polymerization. P(AN-VAc) and nano-Al 2 o 3 According to the mass concentration of 5%, it is dissolved in the solvent tetrahydrofuran to obtain a viscous liquid, nano-Al 2 o 3 The addition amount of the polymer is 20% of the mass of the polymer. After it is completely dissolved, soak the cheap and easy-to-obtain polyethylene PE non-woven fabric support in the gel liquid, take it out after 18 minutes, and then put the PE non-woven fabric coated with the polymer The cloth-supported membrane was passed through a large water-bath tank filled with deionized water to induce phase transfer, followed by drying at 95 °C to remove residual solvents to obtain a lithium-ion battery gel polymer membrane supported by a non-woven fabric support. After the polymer film was cut to an appropriate s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com