Highly conductive heat-resistant aluminum conductor and production process thereof

A production process, heat-resistant aluminum technology, applied in conductors, circuits, electrical components, etc., can solve the problems of increasing power loss and energy consumption, small thermal expansion coefficient, and high erection costs, and achieve improved sag characteristics and small creep. , The effect of low line loss and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

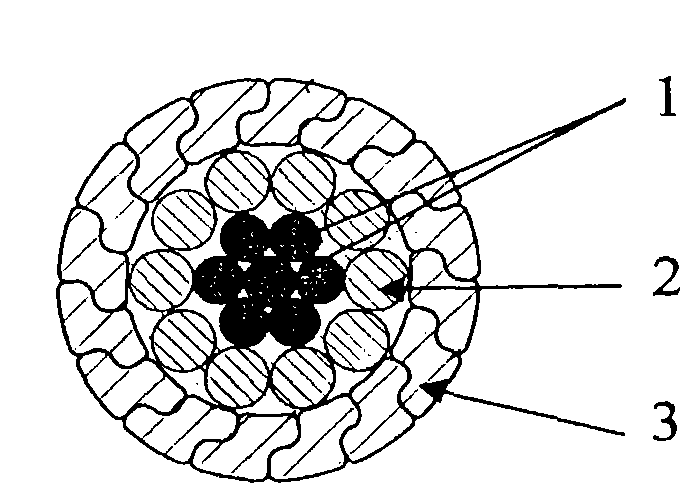

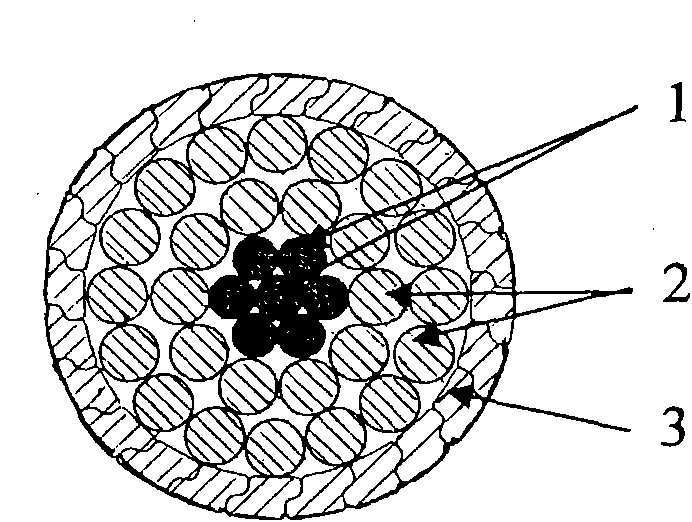

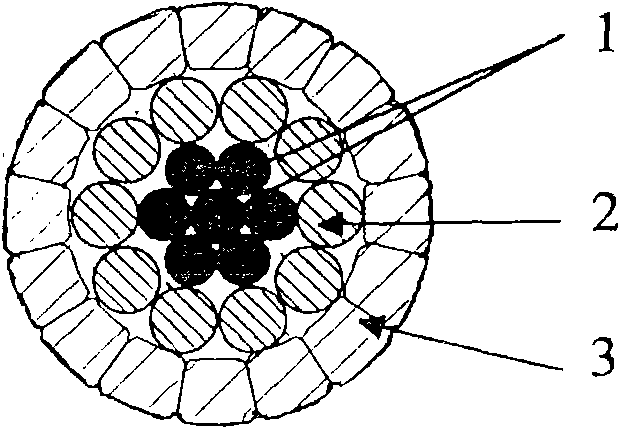

[0018] exist Figure 1 to Figure 6 Among them, a high-conductivity heat-resistant aluminum wire and its production process, including high-strength or ultra-high-strength load-bearing steel core wire 1, high-conductivity heat-resistant aluminum round single wire 2 and high-conductivity heat-resistant aluminum wire 3, its characteristics A steel strand stranded by a plurality of high-strength or extra-high-strength round single steel wires is used as a load-bearing core wire 1, and a high-conductivity heat-resistant aluminum round single wire 2 and an aluminum-shaped wire 3 are concentrically twisted on the outside of it as a conductor; The layers of the above-mentioned high-conductivity heat-resistant aluminum round single wire 2 and aluminum-shaped wire 3 stranded wires are single-layer, two-layer or multi-layer respectively; the above-mentioned high-conductivity heat-resistant aluminum round single wire 2 and aluminum-shaped wire stranded The twisting direction of the adjacen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com