Prestress concrete noise barrier sound absorption inserting plate for high speed railway

A high-speed railway and prefabricated concrete technology, applied in the field of components, can solve the problems of poor fatigue resistance, fatigue damage, inconvenient promotion and use, etc., and achieve good fatigue resistance, improved crack resistance, and significant noise reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

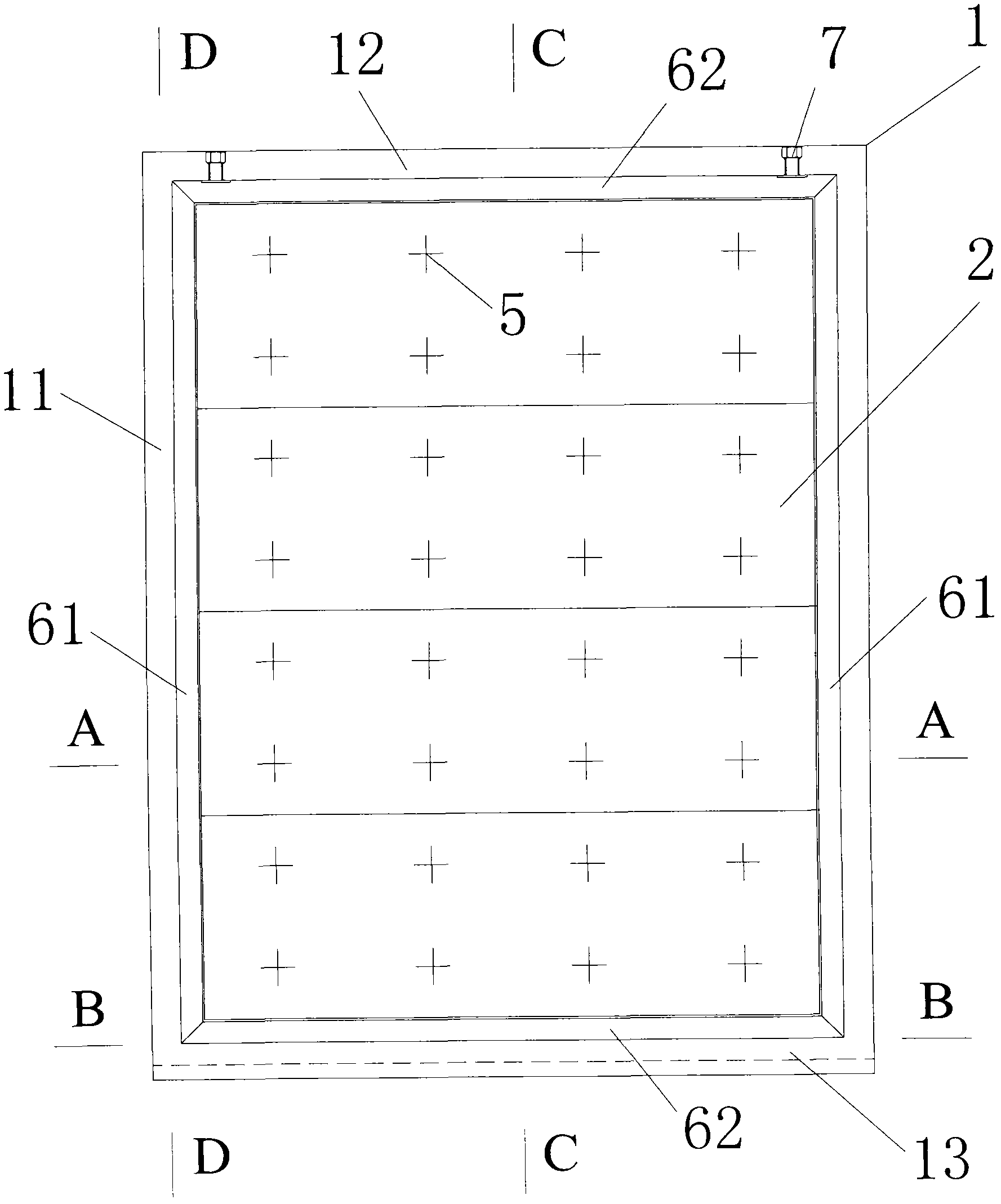

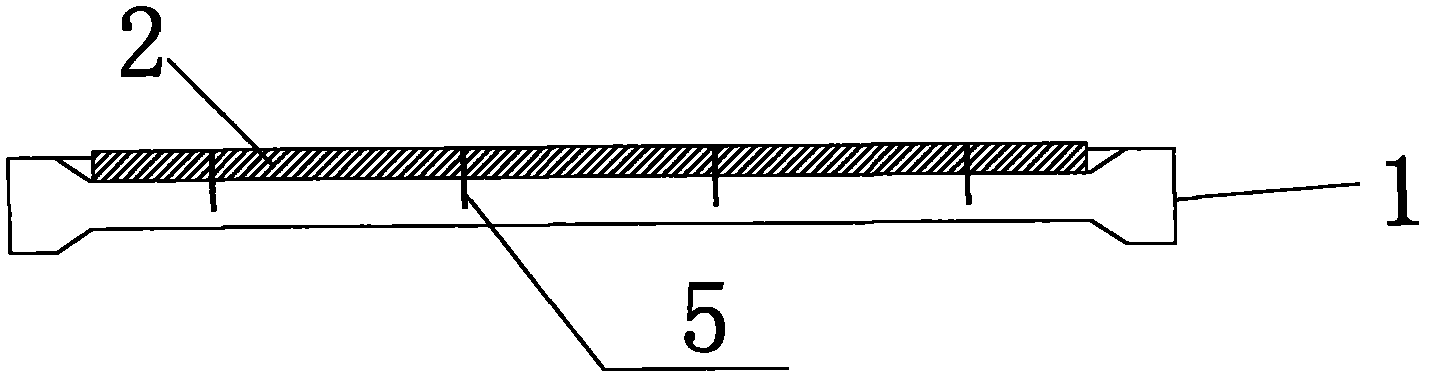

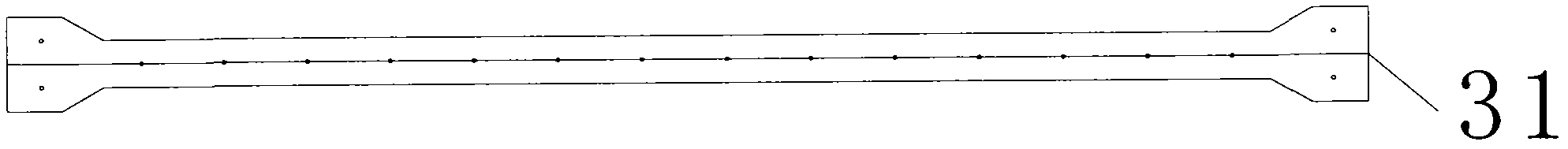

[0044] Such as figure 1 As shown, the prestressed concrete high-speed railway sound barrier sound-absorbing panel includes: prefabricated prestressed concrete unit panel 1, sound-absorbing panel 2, and sound-absorbing panel 2 is installed on the prefabricated prestressed concrete unit panel through the sound-absorbing panel connecting bolt 5 1 on. The prefabricated prestressed concrete unit insert 1 is a rectangular structure, the prefabricated prestressed concrete unit insert 1 is provided with thickened rib columns 11 on the left and right sides, and the prefabricated prestressed concrete unit insert 1 is provided with thickened rib beams on its top 12. The prefabricated prestressed concrete unit insert plate 1 has a thickened rib beam 13 with grooves at its bottom. The prefabricated prestressed concrete unit insert 1 is provided with double-layer horizontal prestressed steel bars 31 on the thickened rib beam on the top and the thickened rib beam with grooves on the bottom,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com