Heat-resistant complex glass fiber sewing thread and preparation method thereof

A sewing thread, high temperature resistant technology, used in fiber processing, yarn, textiles and papermaking, etc., can solve the problems of general chemical resistance, general high temperature resistance, poor folding and wear resistance, etc., to achieve smooth surface and good temperature resistance. , stitch smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

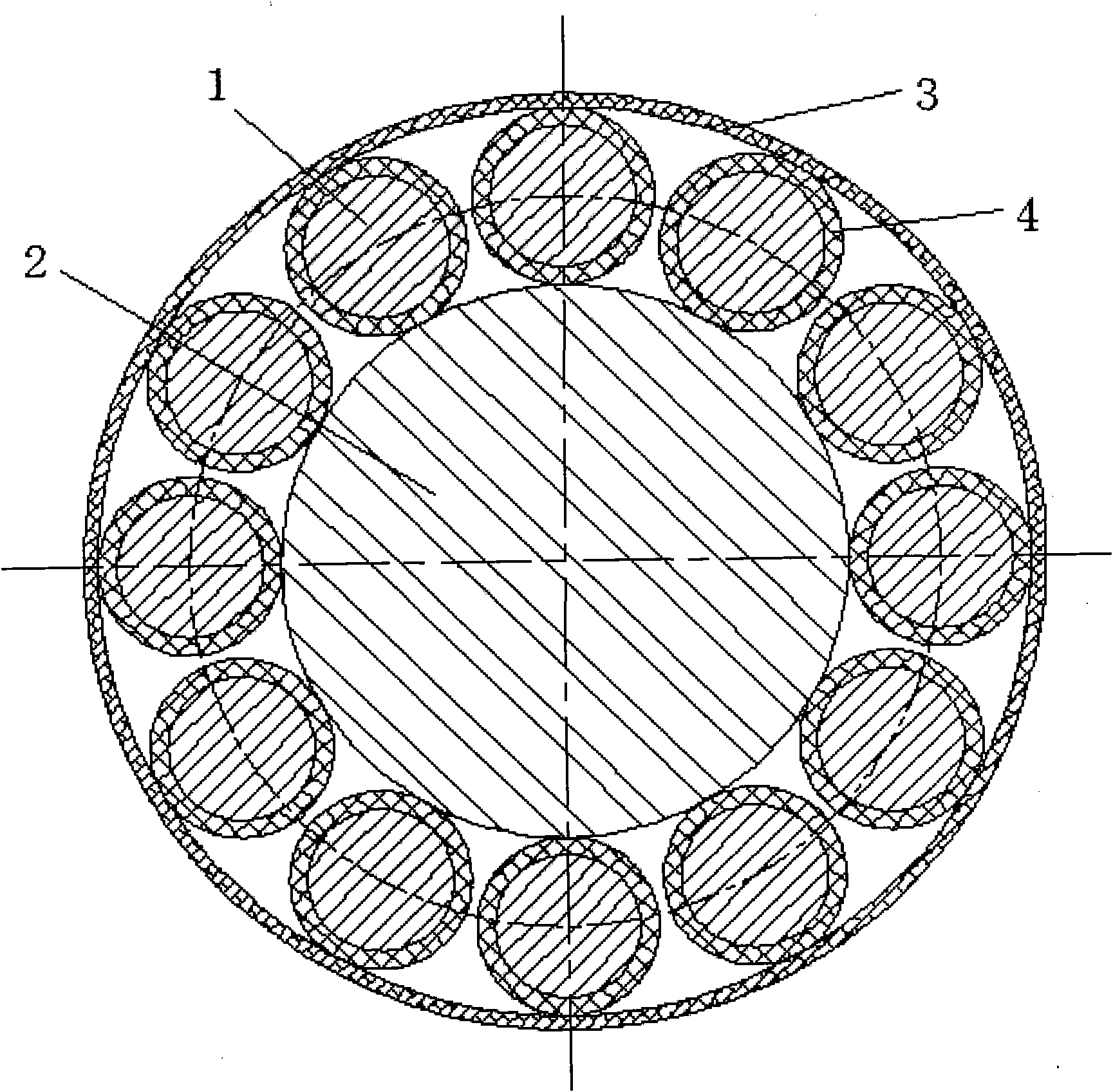

[0024] In the high temperature resistant composite glass fiber sewing thread of this embodiment, the diameter of the glass fiber monofilament 1 is 3.8 μm; the diameter of the metal wire 2 is 20 μm, the elongation is 2.8%, and the tensile strength is 500 MPa.

[0025] The preparation method of the high temperature resistant composite glass fiber sewing thread of the present embodiment comprises the following steps:

[0026] (1) Glass fiber monofilament 1 is drawn and treated with soaking emulsion at the same time to form impregnated layer 4, which is directly treated by raw silk and spun into yarn through the de-solution process;

[0027] (2) the yarn after the solution and the metal wire 2 are plied through the parallel twisting process, and twisted to make the required composite glass fiber sewing thread;

[0028] (3) The composite glass fiber sewing thread described in step (2) is impregnated with the mixed solution, then dried in a pre-dryer, and finally sintered in a sinte...

Embodiment 2

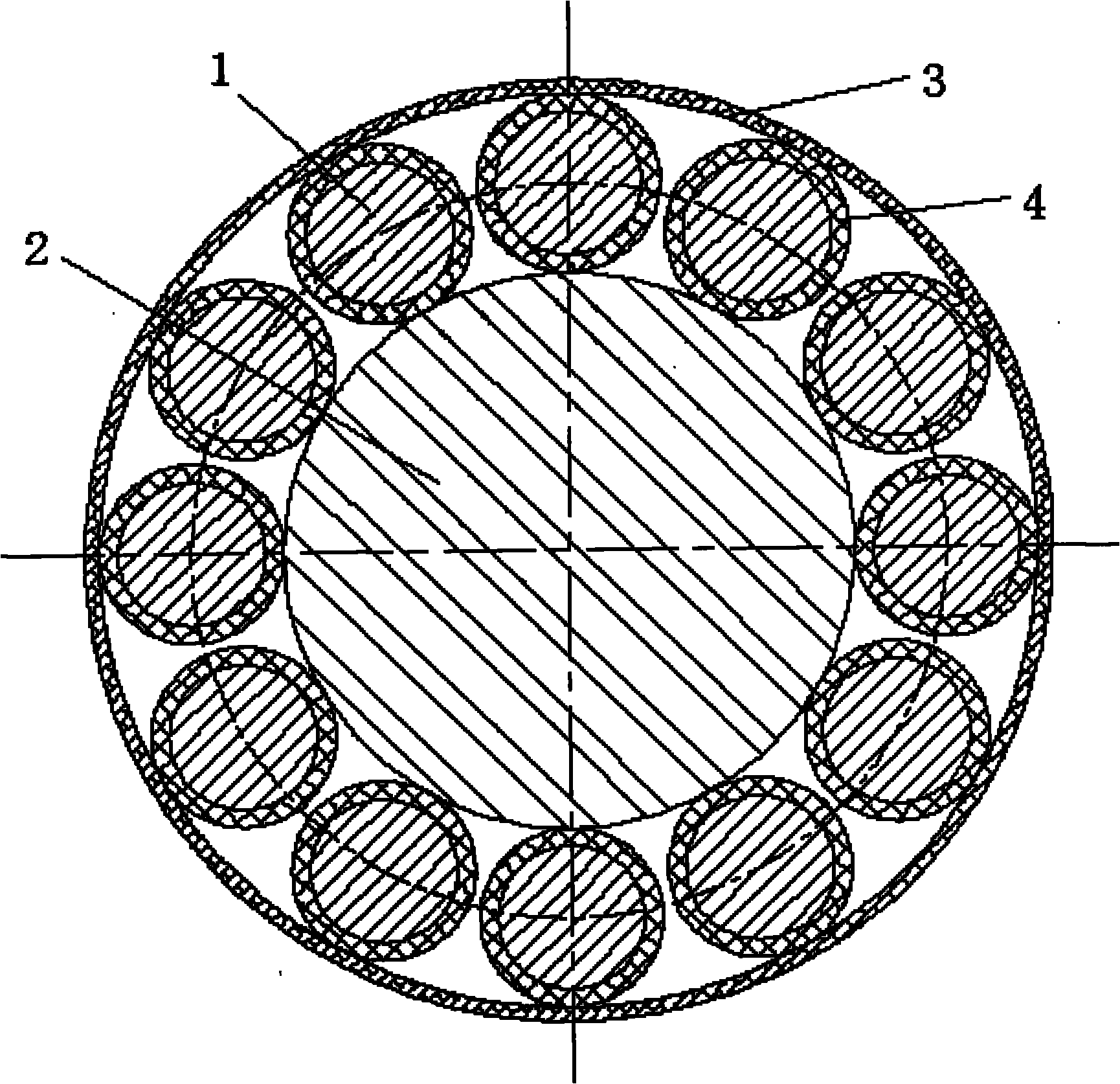

[0033] In the high temperature resistant composite glass fiber sewing thread of this embodiment, the diameter of the glass fiber monofilament 1 is 5.5 μm, the diameter of the metal wire 2 is 10 μm, the elongation is 1.5%, and the tensile strength is 800 MPa.

[0034] The preparation method of the high temperature resistant composite glass fiber sewing thread of the present embodiment comprises the following steps:

[0035] (1) Glass fiber monofilament 1 is drawn and treated with soaking emulsion at the same time to form impregnated layer 4, which is directly treated by raw silk and spun into yarn through the de-solution process;

[0036] (2) the yarn after the solution and the metal wire 2 are plied through the parallel twisting process, and twisted to make the required composite glass fiber sewing thread;

[0037] (3) The composite glass fiber sewing thread described in step (2) is impregnated with the mixed solution, then dried in a pre-dryer, and finally sintered in a sinte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com