Method for solving problem of copper segregation in steel

A technology for molten steel and molten steel, applied in the field of improving the quality of steel, can solve problems such as hazards, and achieve the effects of expanding sources, improving quality, and achieving significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The main harm of copper to steel is that copper is easy to segregate at grain boundaries, which leads to hot brittleness of steel at high temperature. Therefore, if conditions can be created so that copper can be dispersed and precipitated finely in the steel without segregation at the grain boundary, the harm of copper to the steel can be eliminated, and even the harm can be turned into a benefit, which can improve some properties of the steel.

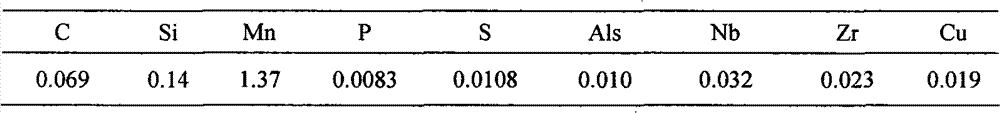

[0031]In this embodiment, low carbon steel is smelted in a 260-ton top-blown converter. The steel smelting process is as follows: after the converter is blown, 52.0 kg of aluminum is firstly added after tapping to carry out pre-deoxidation and alloying treatment of molten steel. Add 83.8kg of recarburizer, 563.0kg of ferrosilicon and 209.0kg of ferroniobium to carry out deoxidation and alloying of molten steel, and then the molten steel enters the LF furnace for refining treatment. After the molten steel is processed, FeS24.3k...

Embodiment 2

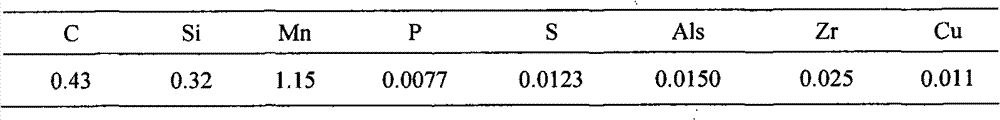

[0037] The difference between this embodiment and Embodiment 1 is that the smelted steel is medium carbon steel. After the converter blowing is completed, 78.0kg of aluminum is added for pre-deoxidation and alloying treatment after the molten steel is tapped. After tapping, 1230.7kg of recarburizer and 1343.3kg of ferrosilicon were added to deoxidize and alloy the molten steel. Then the molten steel enters the LF furnace for refining treatment. After the molten steel is processed, FeS37.26kg and ferromanganese 3652.1kg are added to the steel respectively. Then, the oxygen activity in the steel was measured by a fixed oxygen probe. When the oxygen activity of the molten steel was controlled at 0.0200%, 393.9 kg of iron zirconium was used for the final deoxidation of the molten steel. After the addition of zirconium iron, the molten steel was sedated for 300s. The composition of this steel is shown in Table 2.

[0038] Table 2 Experimental steel composition (wt%) of Example ...

Embodiment 3

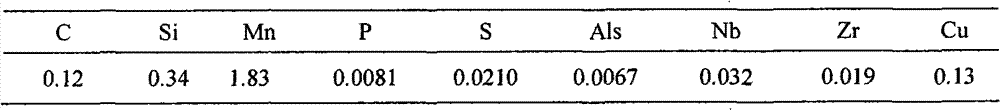

[0042] The difference between this embodiment and Embodiment 1 is that the manganese and sulfur contents in the steel are increased. After the converter blowing, firstly add 34.8kg of aluminum during tapping to carry out pre-deoxidation and alloying treatment of molten steel. change. Then add FeS112.7kg and ferromanganese 4154.6kg to the steel at the same time, and then the molten steel enters the LF refining furnace for processing. After the molten steel is treated, the oxygen activity in the steel is measured by a fixed oxygen probe. When the oxygen activity of the molten steel is controlled at 0.0250%, 299.4 kg of zirconium iron is used for final deoxidation. The molten steel was sedated for 350s after the addition of zirconium iron. The composition of this steel is shown in Table 3.

[0043] Table 3 Experimental steel composition (wt%) of Example 3

[0044]

[0045] No obvious segregation of copper at grain boundaries was found in the samples of the experimental ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com