Emulsifier for improving melting resistance of ice cream and ice cream prepared by utilizing same

A technology of ice cream and emulsifier, which is applied in the field of ice cream and can solve problems such as the influence of monoglyceride on melting resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

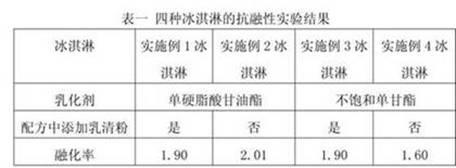

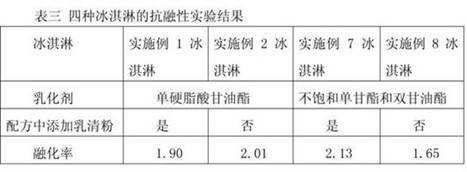

Examples

Embodiment 1

[0025] The emulsifier is glyceryl monostearate (saturated monoglyceride).

[0026] The composition of the ice cream product is: skim milk powder 50g, whey powder 50g, sucrose 120g, malt syrup 50g, fat 40g, carrageenan 0.5g, guar gum 1g, emulsifier 5g, add water to 1000g.

[0027] The preparation process of ice cream is: dissolving skim milk powder and whey powder in water, adding sucrose, maltose syrup, carrageenan, and guar gum, and dissolving to obtain an aqueous solution. At the same time, the fat is heated to dissolve the emulsifier in it to obtain an oil solution. The aqueous and oil solutions are then mixed. Then sterilize at 85°C for 15 minutes, homogenize at 65°C and 18-19Mpa, cool the emulsion to 2-4°C, age at 2-4°C for 4 hours, put the aging liquid into the ice cream machine to freeze, and the soft ice cream produced is in - Hardening at 18°C for more than 4 hours.

Embodiment 2

[0029] The emulsifier is glyceryl monostearate (saturated monoglyceride).

[0030] The composition of the ice cream product is: skim milk powder 100g, sucrose 120g, malt syrup 50g, fat 40g, carrageenan 0.5g, guar gum 1g, emulsifier 5g, add water to 1000g.

[0031] The preparation process of ice cream is: dissolving skim milk powder in water, adding sucrose, maltose syrup, carrageenan, and guar gum, and dissolving to obtain an aqueous solution. At the same time, the fat is heated to dissolve the emulsifier in it to obtain an oil solution. The aqueous and oil solutions are then mixed. Then sterilize at 85°C for 15 minutes, homogenize at 65°C and 18-19Mpa, cool the emulsion to 2-4°C, age at 2-4°C for 4 hours, put the aging liquid into the ice cream machine to freeze, and the soft ice cream produced in - Hardening at 18°C for more than 4 hours.

Embodiment 3

[0033] Emulsifier is unsaturated monoglyceride. The fatty acid groups in unsaturated monoglycerides are mainly C 16 Acid and C 18 acid, where C 18 Acids including oleic and / or linoleic, mono C 16 glycerides and mono-C 18 The weight percentage of acid glyceride is 1:3.

[0034] The composition of the ice cream product is: skim milk powder 50g, whey powder 50g, sucrose 120g, malt syrup 50g, fat 40g, carrageenan 0.5g, guar gum 1g, emulsifier 5g, add water to 1000g.

[0035] The preparation process of ice cream is: dissolving skim milk powder and whey powder in water, adding sucrose, maltose syrup, carrageenan, and guar gum, and dissolving to obtain an aqueous solution. At the same time, the fat is heated to dissolve the emulsifier in it to obtain an oil solution. The aqueous and oil solutions are then mixed. Then sterilize at 85°C for 15 minutes, homogenize at 65°C and 18-19Mpa, cool the emulsion to 2-4°C, age at 2-4°C for 4 hours, put the aging liquid into the ice cream m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com