Cutting device

A cutting device and cutting fluid technology, which is applied in the direction of fine working devices, electrical components, semiconductor/solid device manufacturing, etc., can solve the problems of unstable suction state and hinder the suction of cutting fluid, and achieve the purpose of enhancing the suction force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

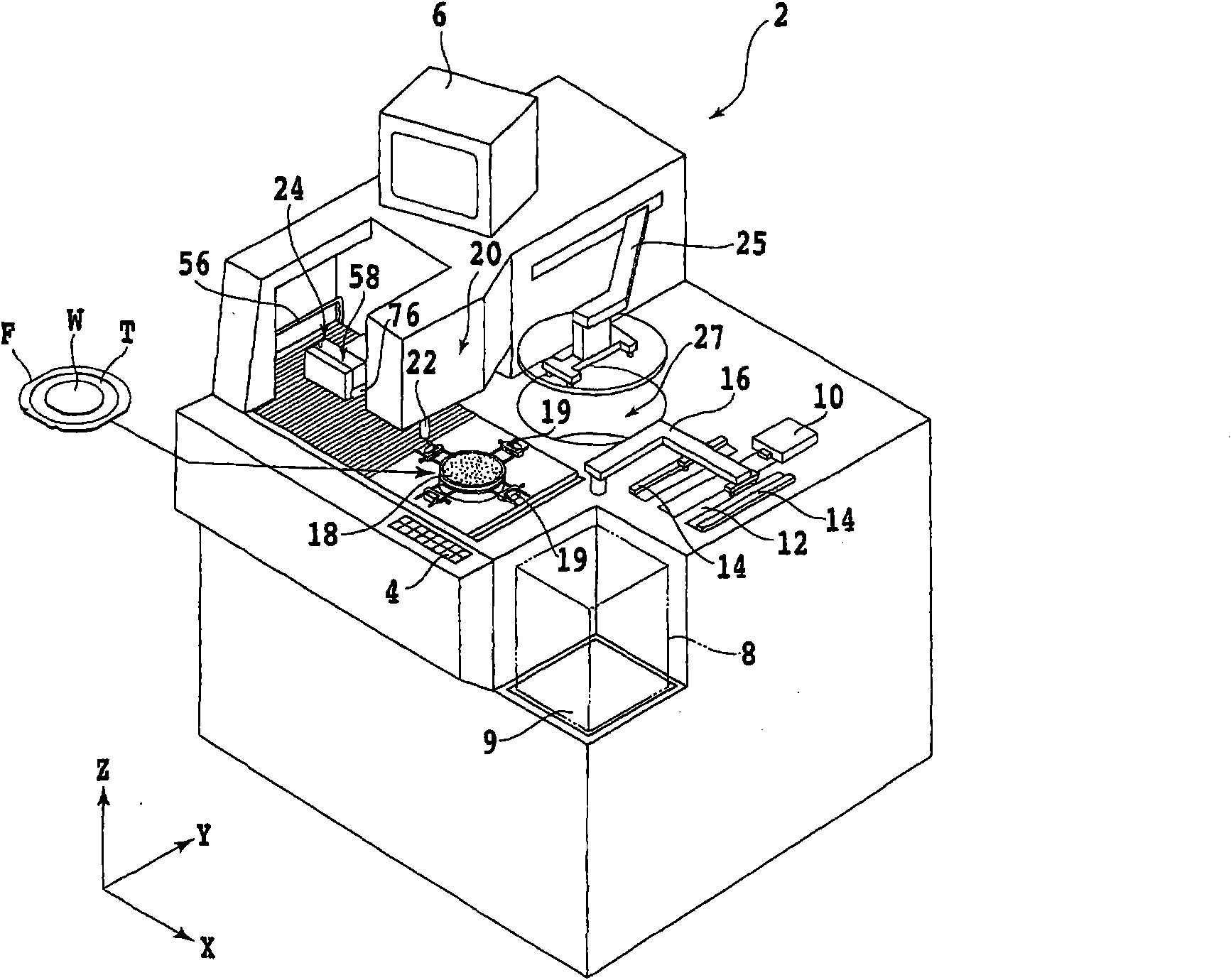

[0022] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. figure 1 The appearance of the cutting device 2 according to the embodiment of the present invention is shown. On the front side of the cutting device 2 is provided an operating member 4 for an operator to input instructions to the device such as machining conditions. A display unit 6 such as a CRT (Cathode Ray Tube: Cathode Ray Tube) for displaying a guidance screen for an operator or an image captured by an imaging unit described later is provided on the upper part of the device.

[0023] Reference numeral 8 denotes a wafer cassette, and a plurality of (for example, 25) semiconductor wafers supported by a ring frame via dicing tapes are accommodated in the wafer cassette 8 . The wafer cassette 8 is placed on a cassette elevator 9 capable of moving up and down.

[0024] Arranged behind the wafer cassette 8 is an unloading and loading member 10 that unloads th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com