System for testing ultrasonic dynamic burning rate of solid propellant

A solid propellant and ultrasonic technology, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, etc., can solve problems such as limited application range, low safety, and inability to measure, and achieve the effect of strong universality, simple and fast operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

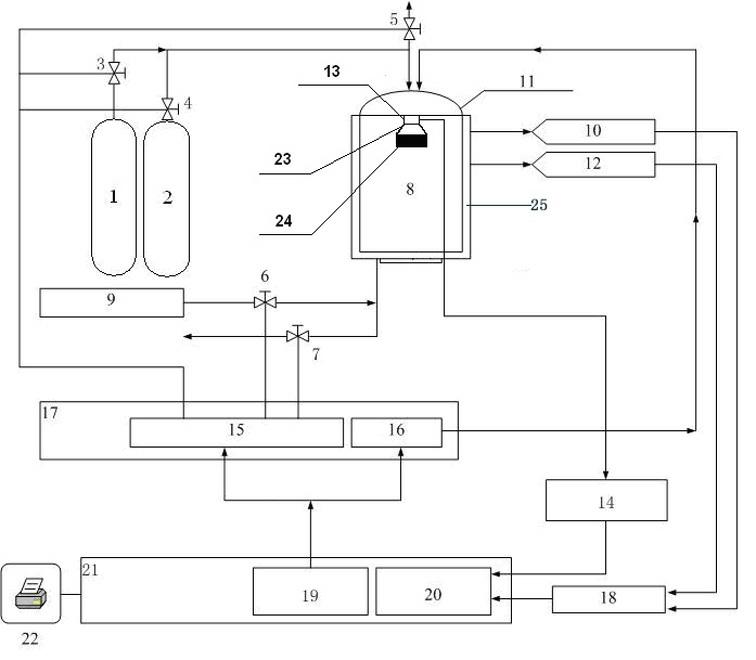

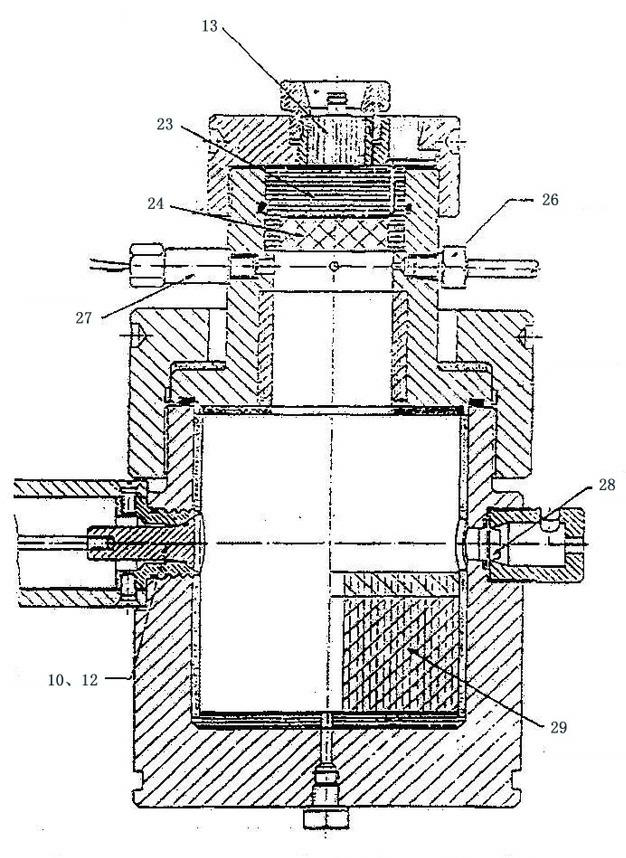

[0019] Ultrasonic solid propellant dynamic burning rate measurement system is based on the basic principle of ultrasonic pulse echo method thickness measurement. During measurement, the ultrasonic probe emits ultrasonic pulses into the solid propellant sample, and when the transmitted wave pulse encounters the propellant burning surface, it returns an echo pulse due to a sudden change in acoustic resistance. Use the instrument to record the echo and the transmitted wave pulse and calculate the time difference (that is, the transit time of the ultrasonic wave in the propellant). Since the speed of sound in the propellant is known, the time difference can be calculated for the solid propellant sample (unburned part) thickness. During the propellant combustion process, the data of the thickness of the propellant over time can be obtained by periodic measurement (that is, the dynamic burning rate of the propellant), and the temperature and pressure of the combustion chamber can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com