Sheared and drawn plate type LED (light-emitting diode) lamp radiator

A technology for LED lamps and radiators, applied in lighting and heating equipment, semiconductor devices for light-emitting elements, cooling/heating devices for lighting devices, etc. Low efficiency and other problems, to achieve the effect of convenient mass production, good heat dissipation effect and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

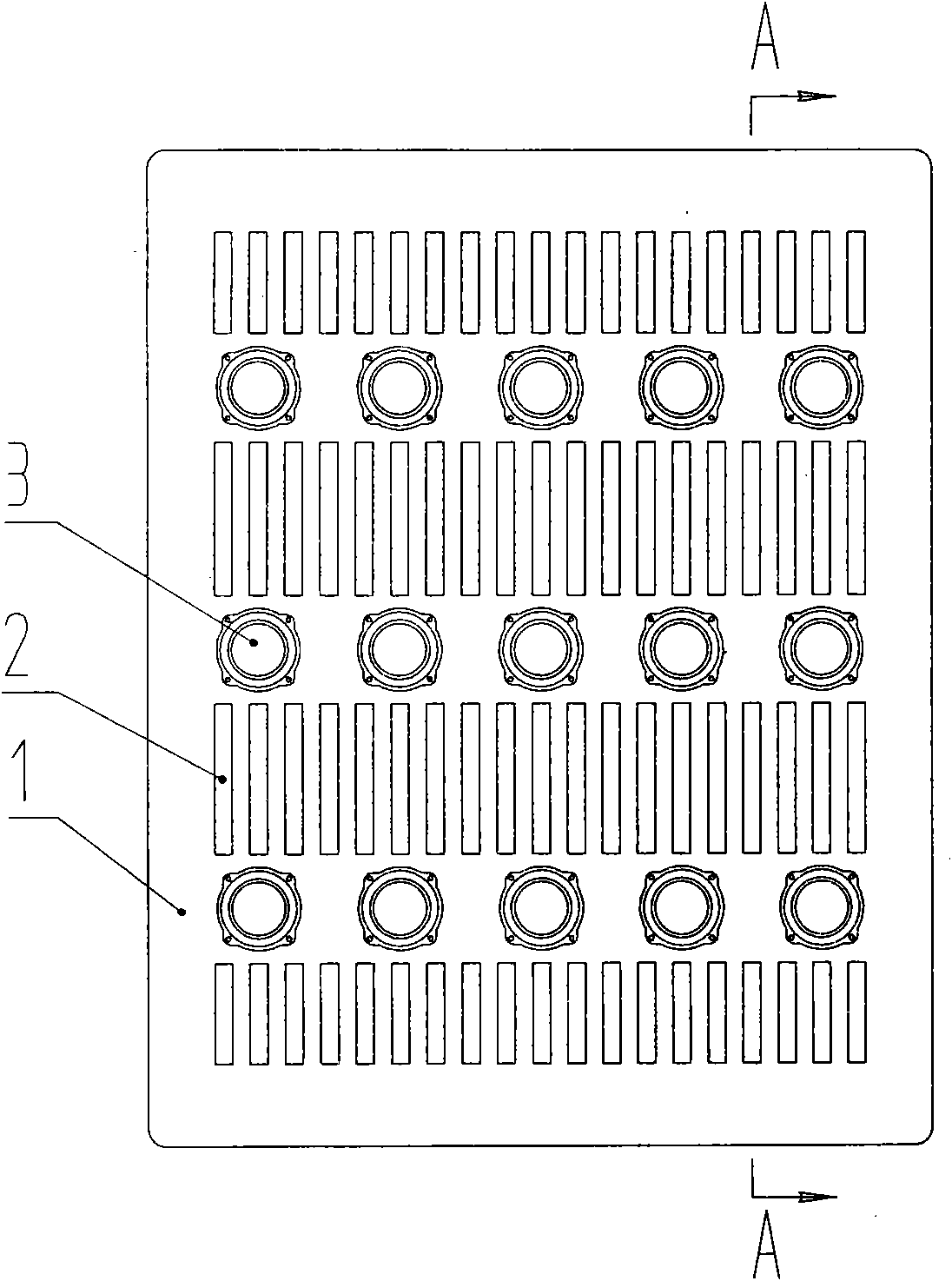

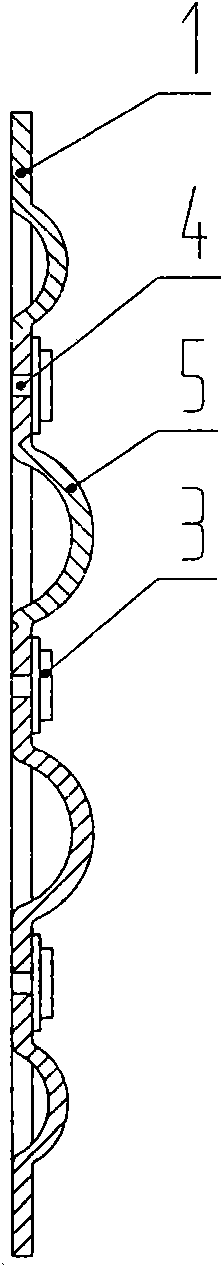

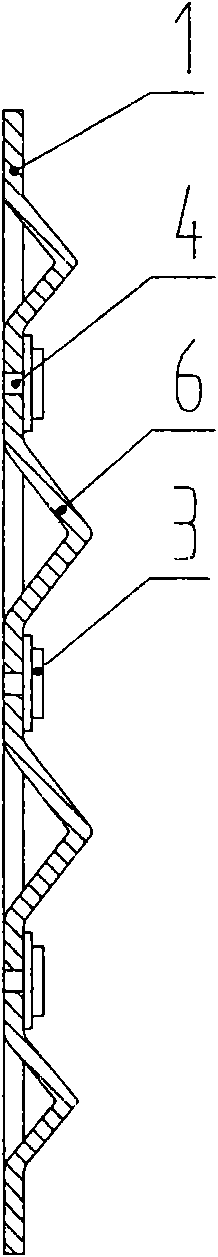

[0016] Such as figure 1 , figure 2 Shown: a shearing and drawing plate type LED lamp heat sink, characterized in that: a number of strip-shaped protrusions 2 are made on the substrate 1, and the two ends of the strip-shaped protrusions 2 are not separated from the substrate 1; the strip-shaped protrusions The shape of 2 is an arc-shaped protrusion; the LED light source 3 is installed on the substrate 1 . If necessary, a wire hole 4 is made on the substrate 1, and the power wire of the LED light source 3 passes through the wire hole 4 to be connected to a power supply.

[0017] The shape of the strip-shaped protrusion 2 is arc-shaped protrusion 5 or triangular protrusion 6 or trapezoidal protrusion 7 or M-shaped protrusion 8 or U-shaped protrusion 9 . During specific implementation, according to the shape of the lamp and the heat dissipation space, the shape of the strip-shaped protrusion 2 can also adopt other shapes.

[0018] Such as Figure 1 to Figure 6 Shown: In order...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com