Stability and pore pressure control technology for loess-substrate waste dump

A control technology and technology for dumping sites, applied in the fields of soil protection, infrastructure engineering, construction, etc., can solve the problems of quantification difficulties and poor technical pertinence, and achieve the effect of improving the mechanical strength of soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

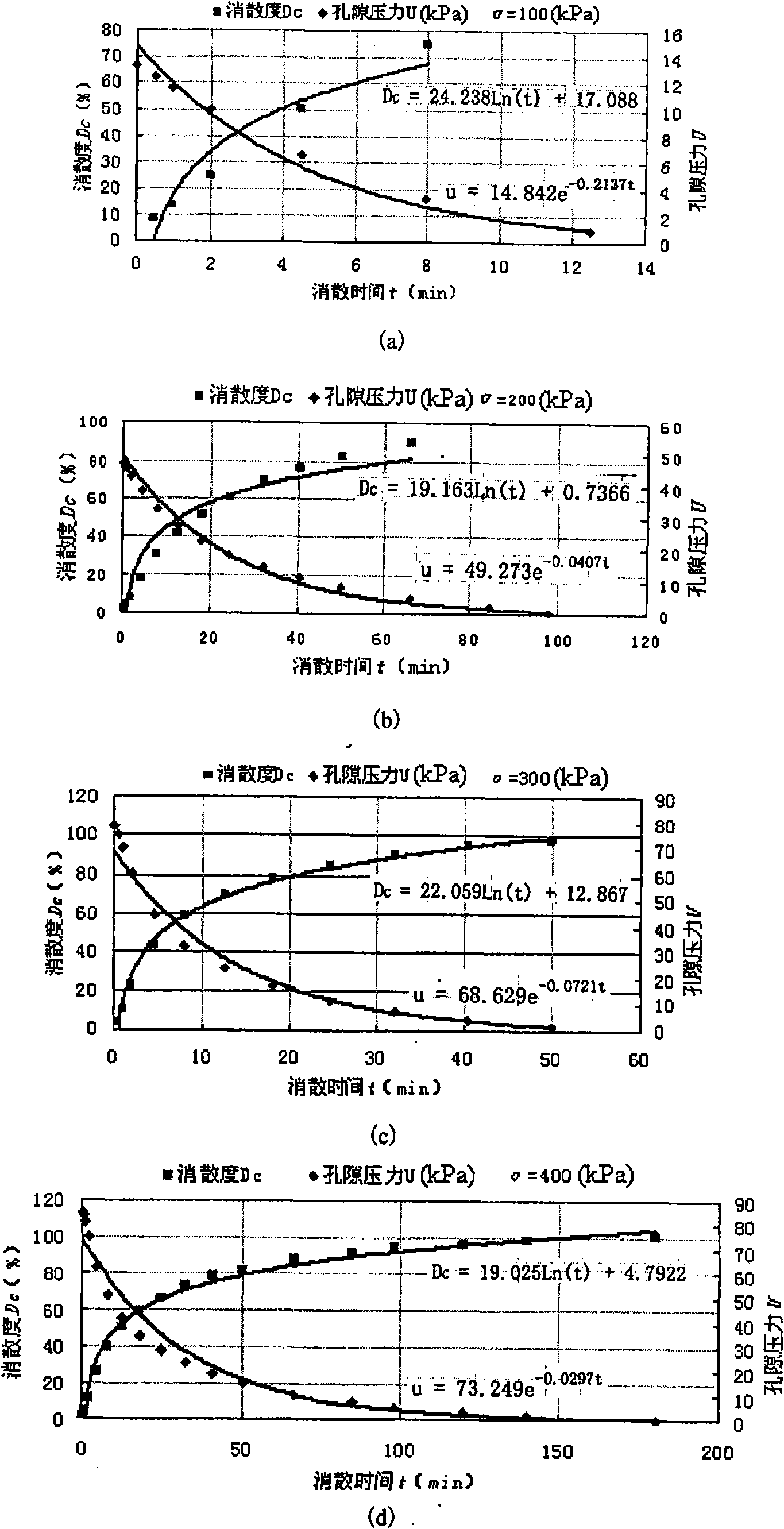

[0021] Embodiment one, see figure 1 , figure 2 , Table 1, Table 2, a stability pore pressure control technology for loess basement dumps. There is an aquifer on the loess basement of the loess dump. Under rainfall or other recharge conditions, the saturated water-bearing loess basement forms on the aquifer. The evolutionary weak layer 11 constitutes the potential slope sliding surface 14. The possible location of the sliding surface is determined according to the geological exploration results. For the selected section, the pore pressure u is obtained by fitting according to the soil mechanics laboratory test and the on-site water pressure meter monitoring of the dump site.

[0022] u=Ce Dt

[0023] In the above formula: u——pore pressure, kPa;

[0024] t——pore pressure dissipation time, min;

[0025] C——related parameters of pore pressure dissipation;

[0026] D——related parameters of pore pressure dissipation.

[0027] A, B, C, D—rel...

Embodiment 2

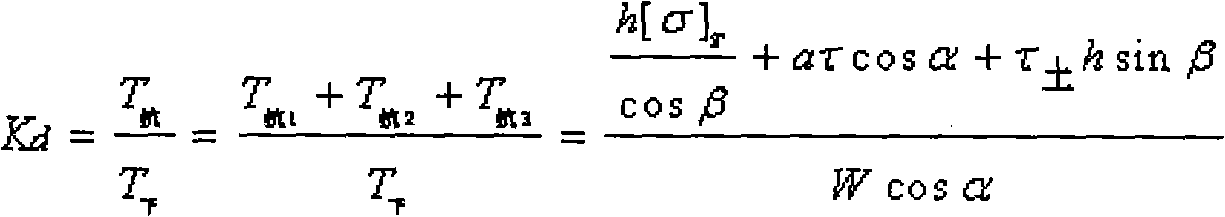

[0078] Embodiment two, see appendix figure 1 , figure 2 , the theory and formula in Table 1, Table 2 and Example 1, when h=138m, [σ] T =153.764kPa, a=240m, τ 0 =66.835kPa,D c =97.73%, α=7°, β=34°, τ 土 = 192.205kPa, W = 64836.8kN, considerably increased the amount of soil displacement. Ask for K d formula calculation

[0079] K d = 138 × 153.764 + 240 × 66.835 × 97.73 % × 0.83 × 0.99 + 192.205 × 0.67 × 240 64836.8 × 0.83 × 0.99 = 0.975

[0080] K d =0.975<1, the soil discharge step of this section stops soil dischar...

Embodiment 3

[0086] Embodiment three, see appendix figure 1 , figure 2 , the theory and formula in Table 1, Table 2 and Example 1, when h=138m, [σ] T =153.764kPa, a=240m, τ 0 =66.835kPa,D c = 43.07%, corresponding to an increase in pore pressure, α = 7°, β = 34°, τ 土 =192.205kPa, W=54880kN, use K d formula calculation

[0087] K d = 138 × 153.764 + 240 × 66.835 × 43.07 % × 0.83 × 0.99 + 192.205 × 0.67 × 240 54880 × 0.83 × 0.99 = 0.992

[0088] K d =0.992<1, adopt the same control measures as in Embodiment 2. The specific conten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com