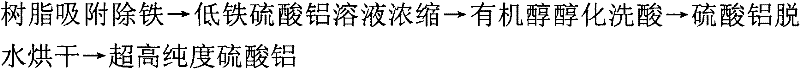

Method for removing impurity iron in aluminum sulfate solution through ion exchange

A technology of ion exchange and cation exchange, applied in the field of ion exchange removal of impurity iron in aluminum sulfate solution, can solve the problems of large investment in production equipment, complicated process, high energy consumption, etc., and achieve high iron removal efficiency, simple operation, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: the thick aluminum sulfate solution that concentration is 30%~60%, is adjusted to pH value 1~3 with sulfuric acid, is pressed into the resin column that D001 macroporous cationic resin is housed with corrosion-resistant pump and carries out iron removal, The treatment temperature is 65° C., and the flow rate of the crude aluminum sulfate solution is 4 times the resin volume / h during treatment to obtain a low-iron aluminum sulfate solution.

[0030] After the adsorption and saturation of the macroporous cationic resin, the adsorption capacity of the resin is recovered through elution and regeneration. The elution conditions are: the eluent adopts hydrochloric acid with a concentration of 10%, the elution temperature is 50° C., and the flow rate of hydrochloric acid is 1 times the resin volume / h, a total of 2 times the resin volume of hydrochloric acid was used for elution; the concentration of 10% hydrochloric acid was used for regeneration, the temperature ...

Embodiment 2

[0033] Embodiment 2: the aluminum sulfate thick liquid that concentration is 30%, is adjusted to pH value 1 with sulfuric acid, is pressed into the resin column that JK008 macroporous cationic resin is housed with corrosion-resistant pump and carries out iron removal, and treatment temperature is 90 ℃ , the flow rate of the crude aluminum sulfate solution is 2 times the resin volume / h during processing, and a low-iron aluminum sulfate solution is obtained.

[0034]When the macroporous cationic resin is adsorbed and saturated, the resin can recover its adsorption capacity through elution and regeneration. The elution conditions are as follows: the eluent adopts hydrochloric acid with a concentration of 8%, the elution temperature is 30° C., and the flow rate of hydrochloric acid is 2 times the resin volume / h, a total of 1 times the resin volume of hydrochloric acid was used for elution; the concentration of 8% hydrochloric acid was used for regeneration, the temperature was 20°C...

Embodiment 3

[0037] Embodiment 3: the thick aluminum sulfate solution that concentration is 40%, is adjusted to pH value 2 with sulfuric acid, is pressed into the resin post that SPC-1 macroporous cationic resin is housed with corrosion-resistant pump and carries out deironing, and processing temperature is 70°C, the flow rate of the crude aluminum sulfate solution is 3 times the resin volume / h during treatment, and a low-iron aluminum sulfate solution is obtained.

[0038] When the macroporous cationic resin is adsorbed and saturated, the resin is eluted and regenerated to restore its adsorption capacity. The elution conditions are: water is used as the eluent, the elution temperature is 60°C, and the water flow rate is 1 times the resin volume / h , a total of 3 times the resin volume of water was used for elution; a concentration of 6% hydrochloric acid was used for regeneration, the temperature was 50°C, and the flow rate of hydrochloric acid was 3 times the resin volume / h, and a total of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com