Artificial tooth root or joint material and microarc oxidation preparation method thereof

A technology of artificial tooth root and micro-arc oxidation, which is used in dental preparations, dentistry, dental prostheses, etc., to achieve the effects of excellent wear and corrosion resistance, improved antibacterial ability, and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

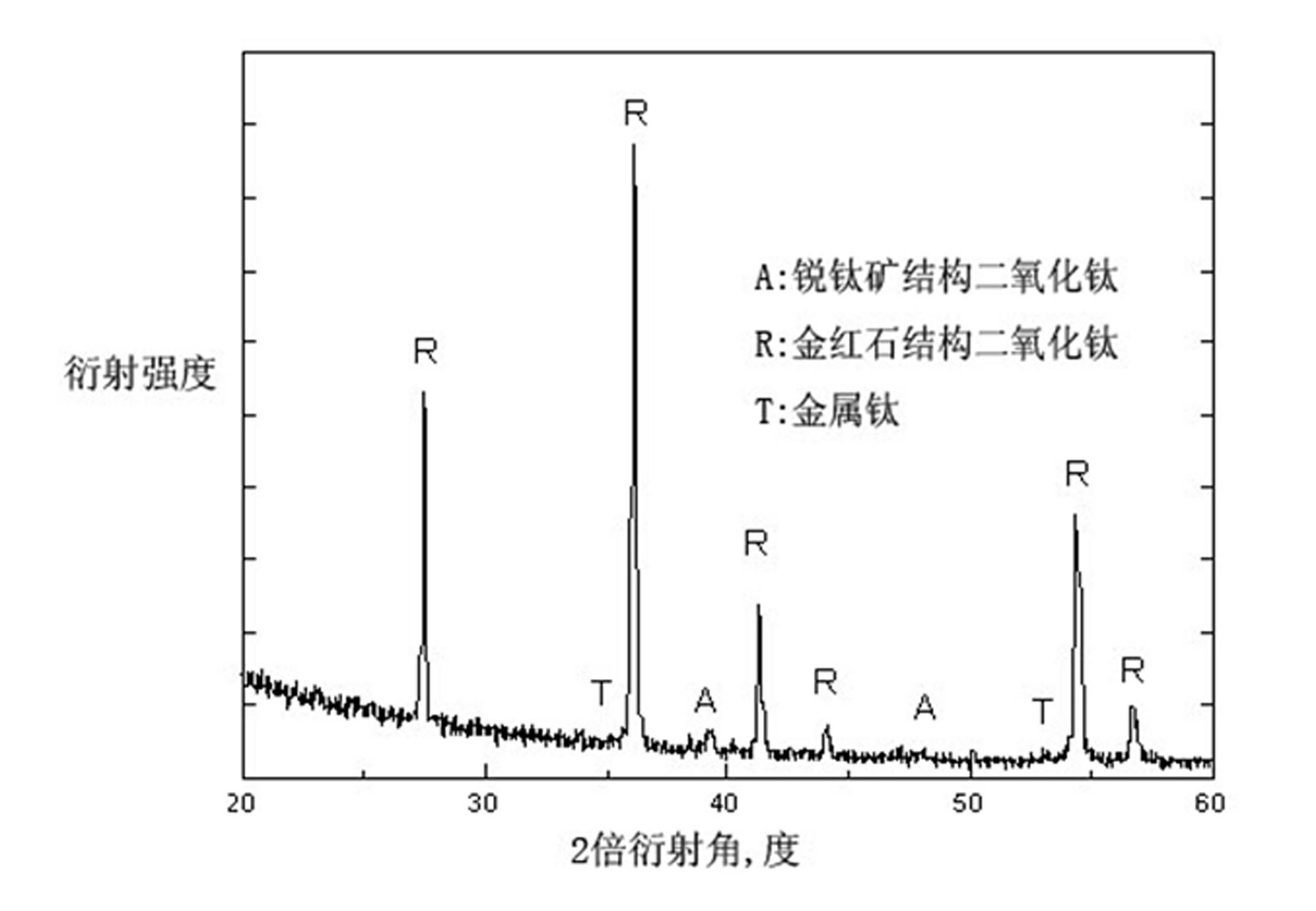

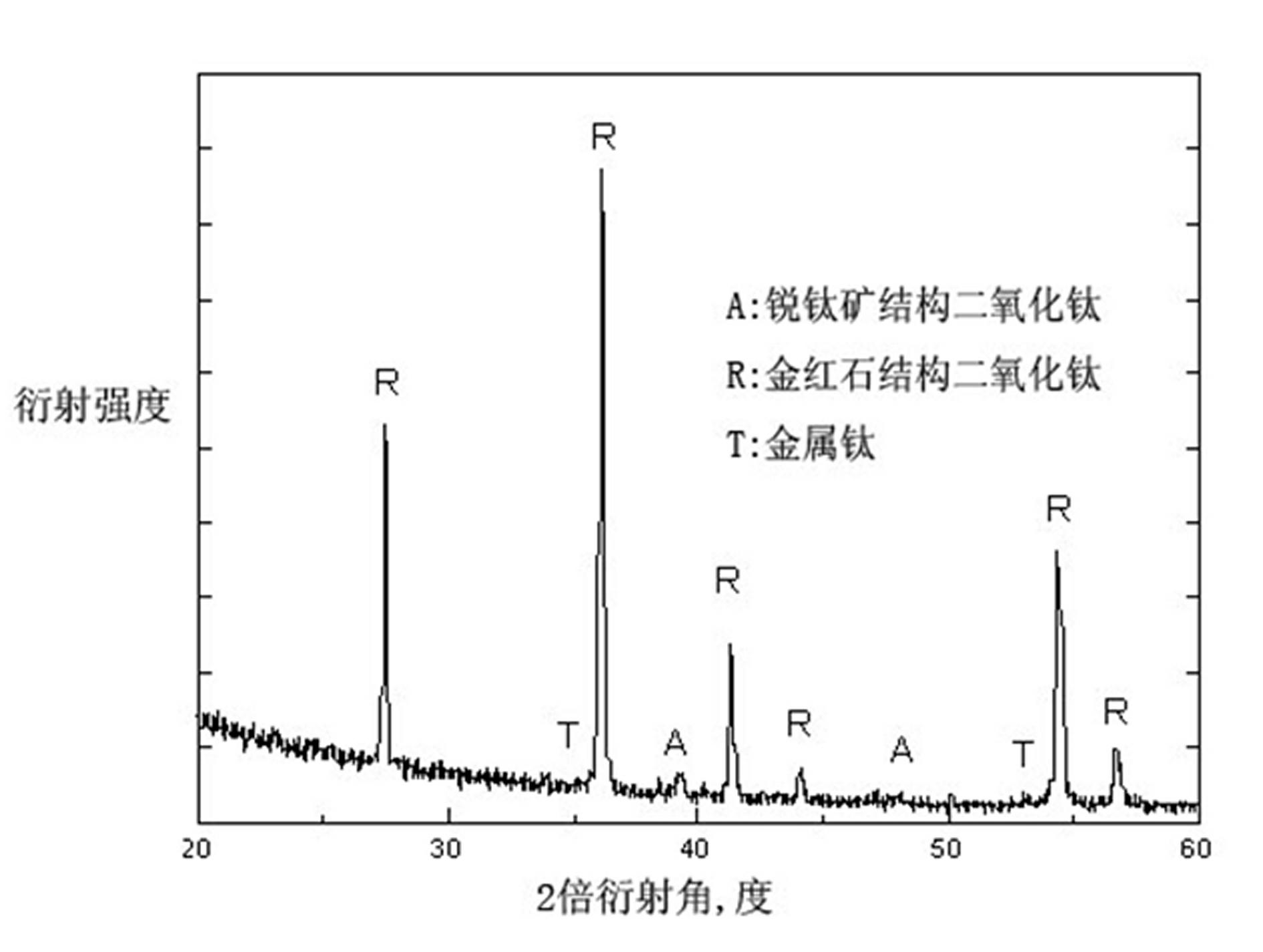

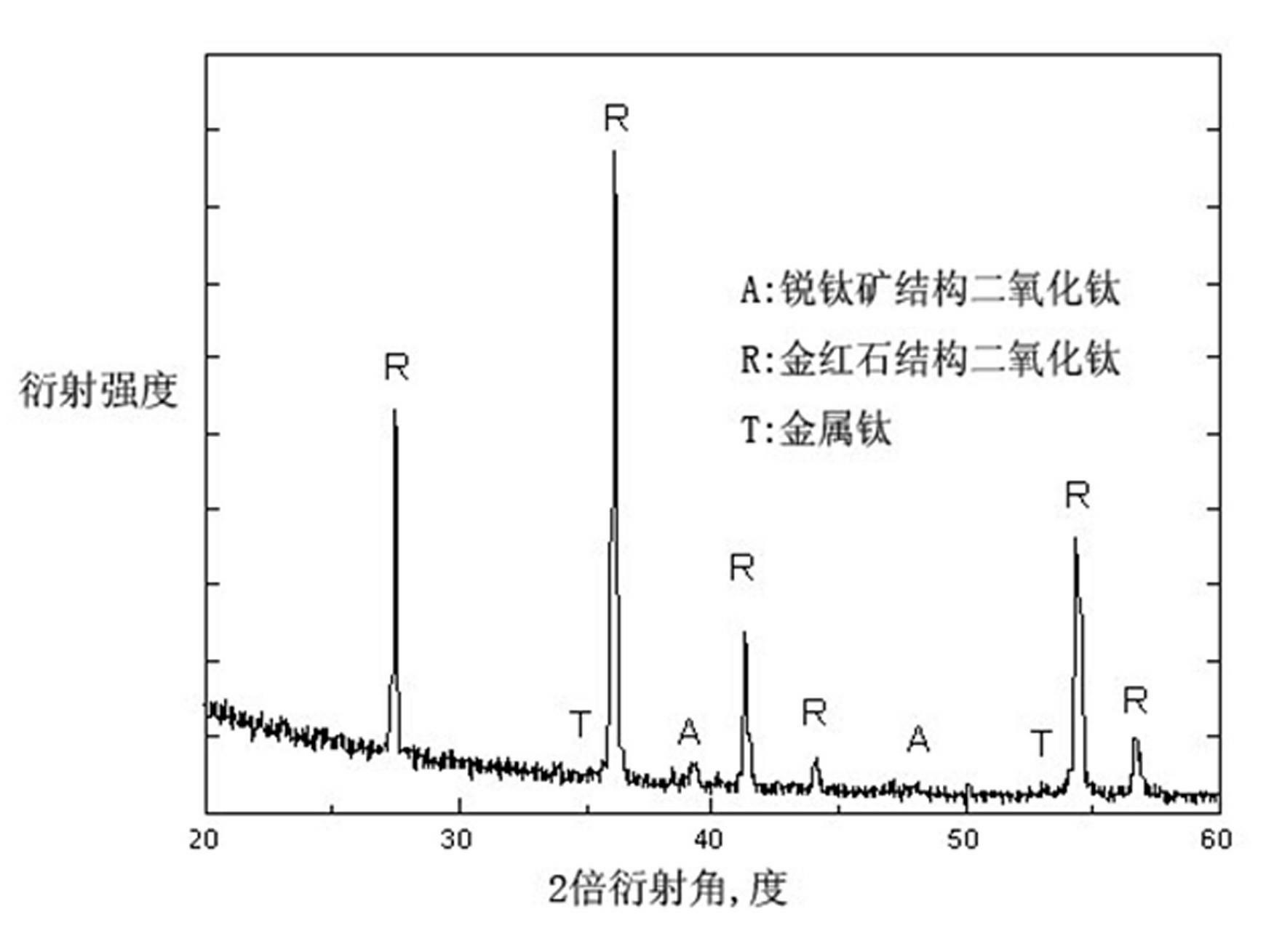

Image

Examples

Embodiment 1

[0028] (1) Firstly, use pure medical titanium to process the artificial tooth root;

[0029] (2) Artificial tooth root pretreatment: use metallographic sandpaper with labels of 600#, 800#, and 1000# to polish and polish the artificial tooth root step by step from coarse sand to fine sand, and then ultrasonically clean it with acetone, 70% alcohol and distilled water , dry and set aside.

[0030] (3) Configuration of electrolyte and addition of zinc and cerium elements: use sodium carbonate solution system, configure 10L sodium carbonate solution with a concentration of 20g / L and potassium hydroxide solution with a concentration of 1g / L; then add 0.1~0.5mmol / 1 L of zinc chloride and 0.1-0.5 mmol / L of cerium chloride were stirred and dissolved at a constant temperature of 40 degrees Celsius, and set aside;

[0031](4) Micro-arc oxidation and pore size regulation of artificial tooth root: place the artificial tooth root in the electrolytic cell of the bipolar pulse micro-arc ox...

Embodiment 2

[0035] (1) First choose Ti6Al4V alloy to process the artificial joint;

[0036] (2) Artificial joint pretreatment: use the metallographic sandpaper of 600#, 800#, and 1000# to polish the artificial joint step by step from coarse sand to fine sand, and then ultrasonically clean it with acetone, 70% alcohol and distilled water , dry and set aside.

[0037] (3) Configuration of electrolyte and addition of zinc and cerium elements: use sodium carbonate solution system, configure 10L sodium carbonate solution with a concentration of 20g / L and potassium hydroxide solution with a concentration of 1g / L; then add 0.1~0.5mmol / 1 L of zinc chloride and 0.1-0.5 mmol / L of cerium chloride were stirred and dissolved at a constant temperature of 40 degrees Celsius, and set aside;

[0038] (4) Micro-arc oxidation and pore size regulation of artificial joints: place the artificial joint in the electrolytic cell of the bipolar pulse micro-arc oxidation equipment and add the prepared electrolyte...

Embodiment 3

[0041] (1) Firstly, use pure medical titanium to process the artificial tooth root;

[0042] (2) Artificial tooth root pretreatment: use metallographic sandpaper with labels of 600#, 800#, and 1000# to polish and polish the artificial tooth root step by step from coarse sand to fine sand, and then ultrasonically clean it with acetone, 70% alcohol and distilled water , dry and set aside.

[0043] (3) Configuration of electrolyte and addition of zinc and cerium elements: use sodium carbonate solution system, configure 10L sodium carbonate solution with a concentration of 20g / L and potassium hydroxide solution with a concentration of 1g / L; then add 0.1~0.5mmol / 1 L of zinc chloride and 0.1-0.5 mmol / L of cerium chloride were stirred and dissolved at a constant temperature of 40 degrees Celsius, and set aside;

[0044] (4) Micro-arc oxidation of artificial tooth root: place the artificial tooth root in the electrolytic cell of the bipolar pulse micro-arc oxidation equipment and ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com