Method for producing soft sheet

A manufacturing method and sheet technology, applied to flat products, applications, household appliances, etc., can solve problems such as multiple calendering times, achieve the effects of reducing calendering times, increasing yield, and promoting fibrosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

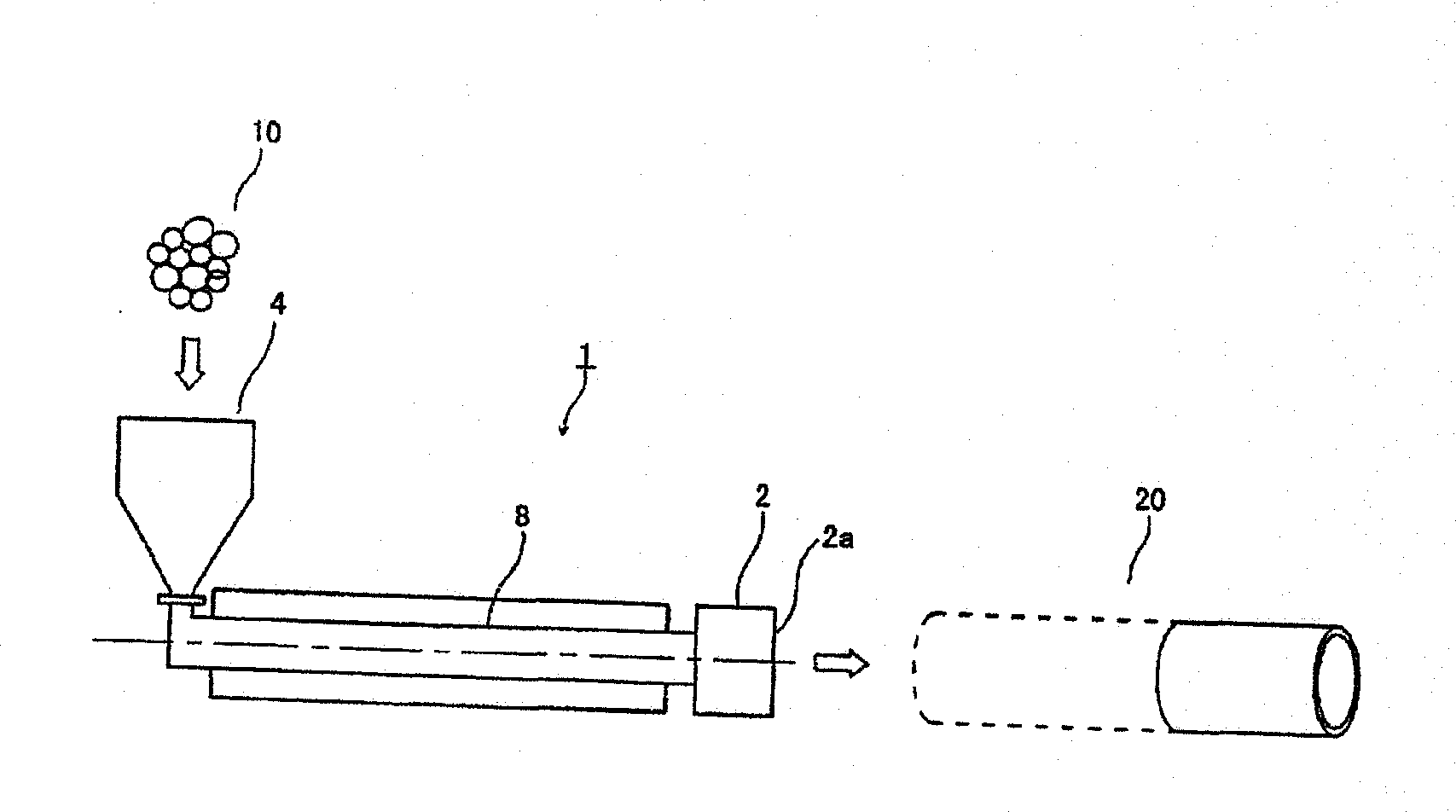

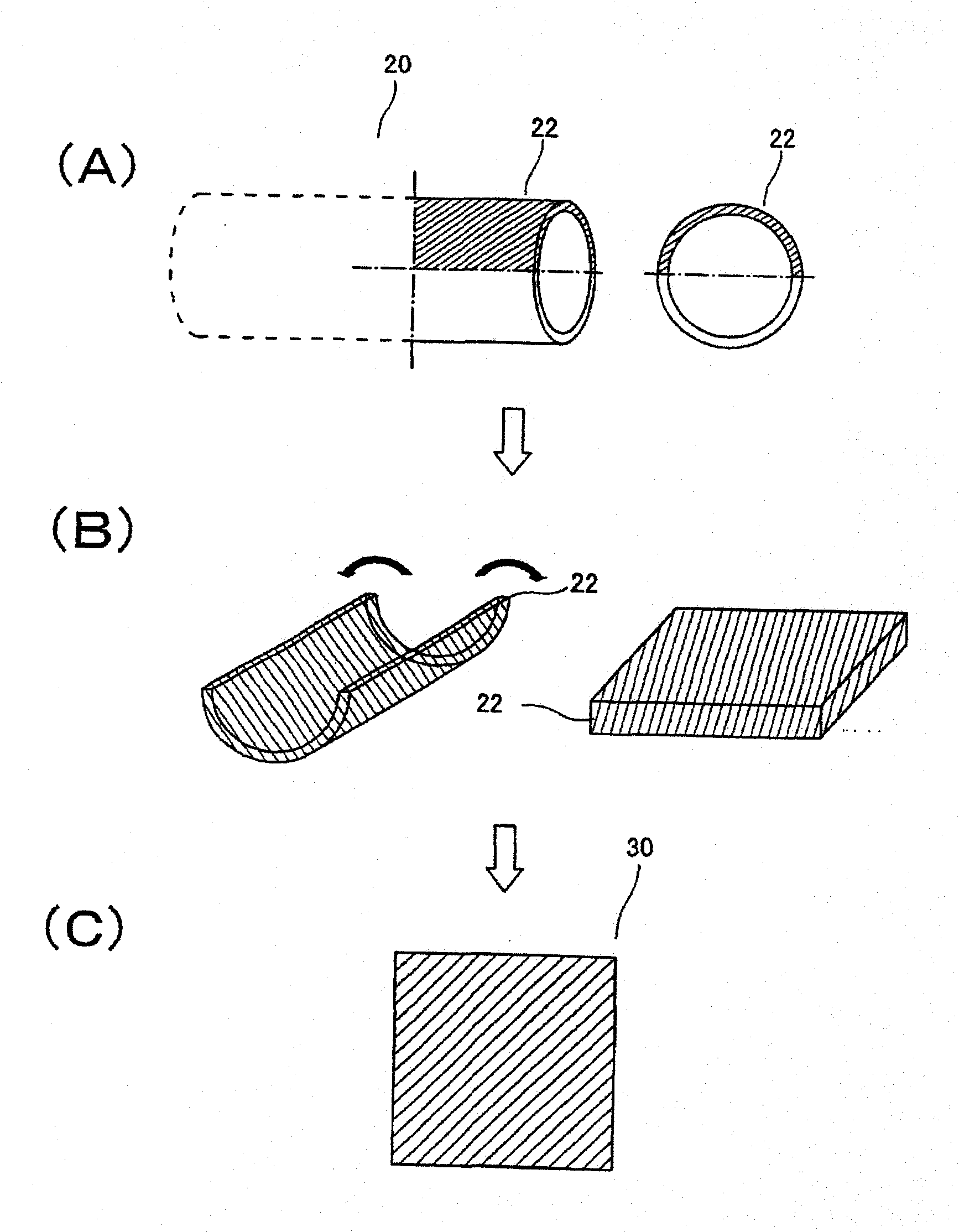

[0058] Hereinafter, examples and comparative examples of the present invention will be described in comparison. In the description below, the figure 1 with figure 2 The manufacturing method of the soft sheet that the present invention relates to shown is embodiment, and with Figure 4 with Figure 5 The production method of the flexible sheet according to the prior art shown is a comparative example.

[0059] In addition, these Examples and a comparative example are an Example and a comparative example for explaining this invention more concretely, and this invention is not limited to the range of an Example.

[0060] (raw material)

[0061] The raw materials of Example material 10 and Comparative example material 110 are shown in Table 1.

[0062] [Table 1]

[0063] project Product name Company Name Example comparative example PTFE Teflon 6-J DuPont-Mitsui Fluorochemicals Corporation 47% by weight 46% by weight clay Crown Clay S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compression ratio | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| softness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com