Method for preparing all-solid-state reference electrode (RE) based on EB-PVD (electron beam physical vapor deposition) and Sol-Gel

A reference electrode and all-solid-state technology, applied in the field of chemistry, can solve the problems of electrode potential instability, service life susceptible to environmental factors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

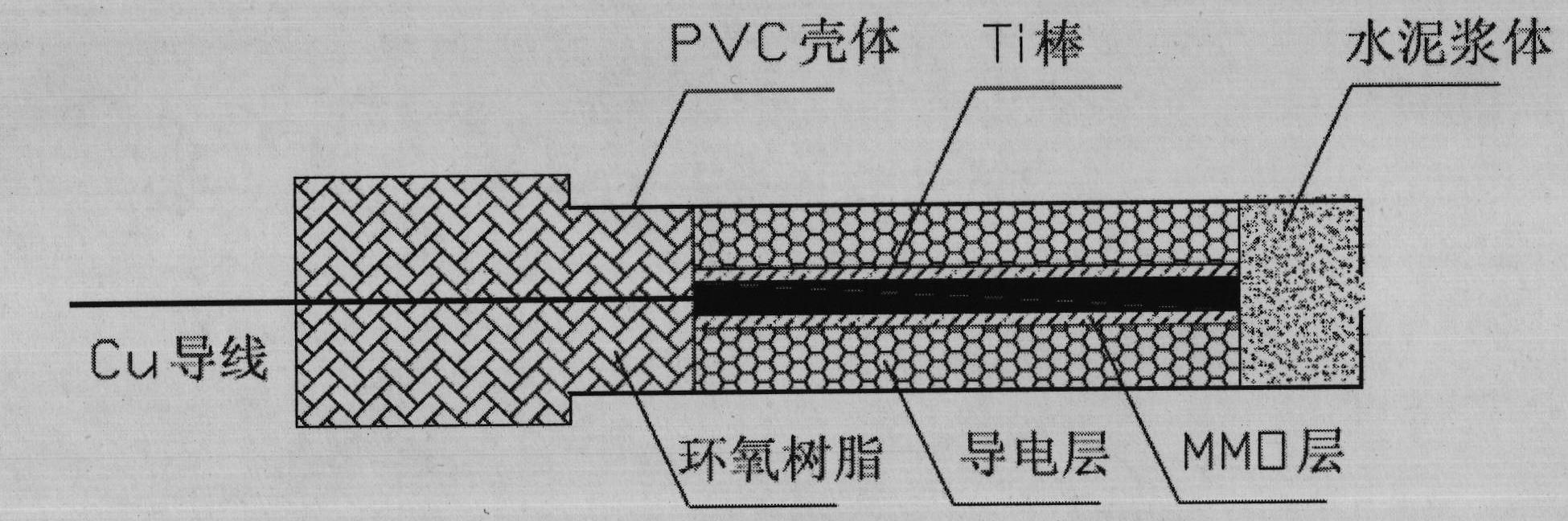

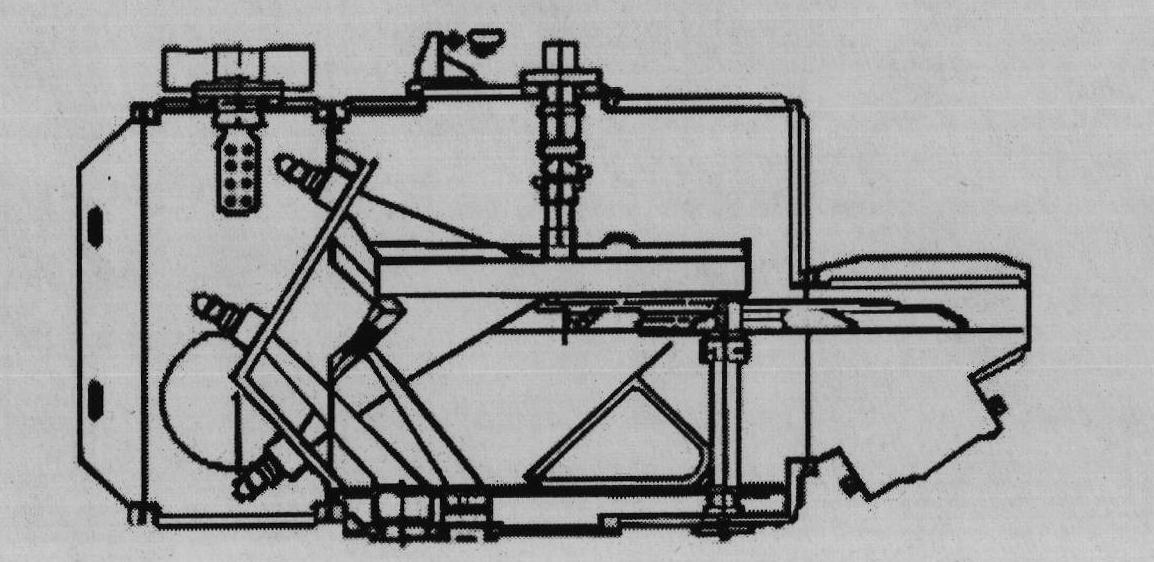

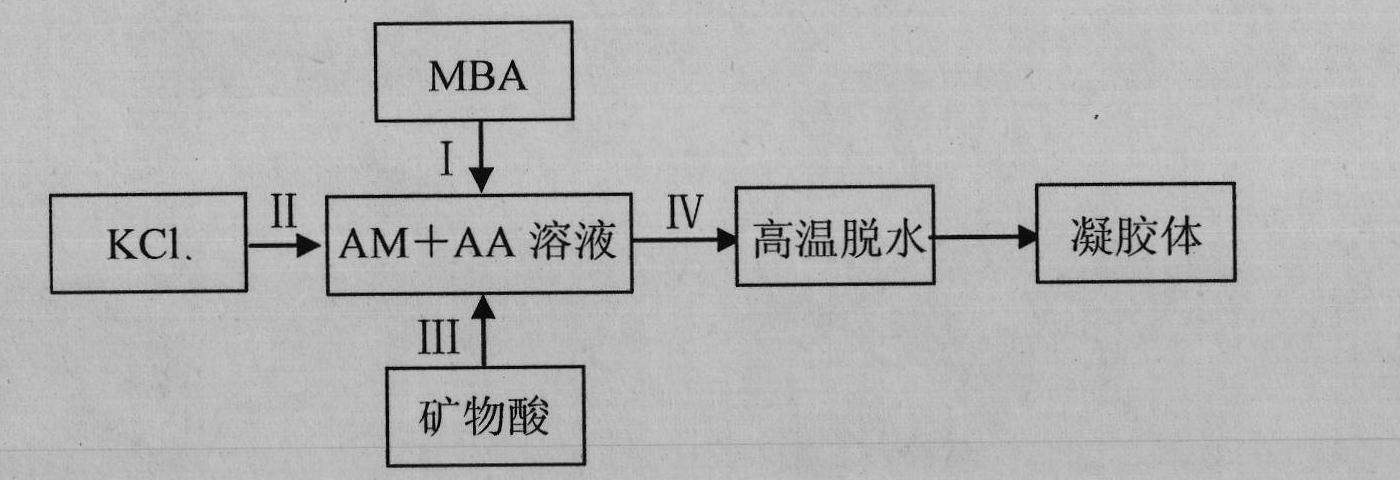

[0026] Example 1: Combining figure 1 , figure 2 , image 3 , a method for preparing an all-solid-state reference electrode based on EB-PVD and Sol-Gel in the present invention, firstly, adopting the EB-PVD technology satisfying large-scale industrial production, depositing a Mo / Ta binary alloy film on a Ti substrate, and then For the as-prepared film under control of O 2 Post-oxidation treatment is carried out under the atmosphere to form a mixed metal oxide layer, so that the binary alloy film layer has the function of a reference electrode; secondly, acrylamide and acrylic acid are used as carriers to prepare a conductive functional layer of Sol-Gel composite material that maintains the stability of the electrode potential ; Finally, integrate the prepared reference electrode functional layer and conductive layer to construct an all-solid reference electrode with a five-layer structure; the specific steps are as follows:

[0027] Step 1: Preparation of functional core of...

Embodiment 2

[0039] Example 2: Combining figure 1 , figure 2 , image 3 , Figure 4 The preparation method of the all-solid-state reference electrode based on EB-PVD and Sol-Gel of the present invention comprises the following specific steps:

[0040] 1. Preparation of MMO reference electrode functional core

[0041] The preparation of MMO includes two processes of EB-PVD state and oxidation state. By optimizing the EB-PVD deposition process parameters, the as-prepared binary alloy film was obtained on the Ti rod; furthermore, the as-prepared alloy film was processed by controlling the oxygen partial pressure oxidation treatment. use figure 2 The alloy film was prepared by dual-source evaporation EB-PVD, and the preparation process was optimized by adjusting parameters such as substrate temperature, deposition rate, target-base distance, and steam incident angle. In the process of changing the ratio of the substrate temperature Ts to the melting point Tm of the evaporation material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com