Dry leak testing machine

A leak tester, dry technology, applied in the direction of measuring the acceleration and deceleration rate of fluid, using liquid/vacuum for liquid tightness measurement, etc. Damage and other problems, to achieve the effect of intuitive test results and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

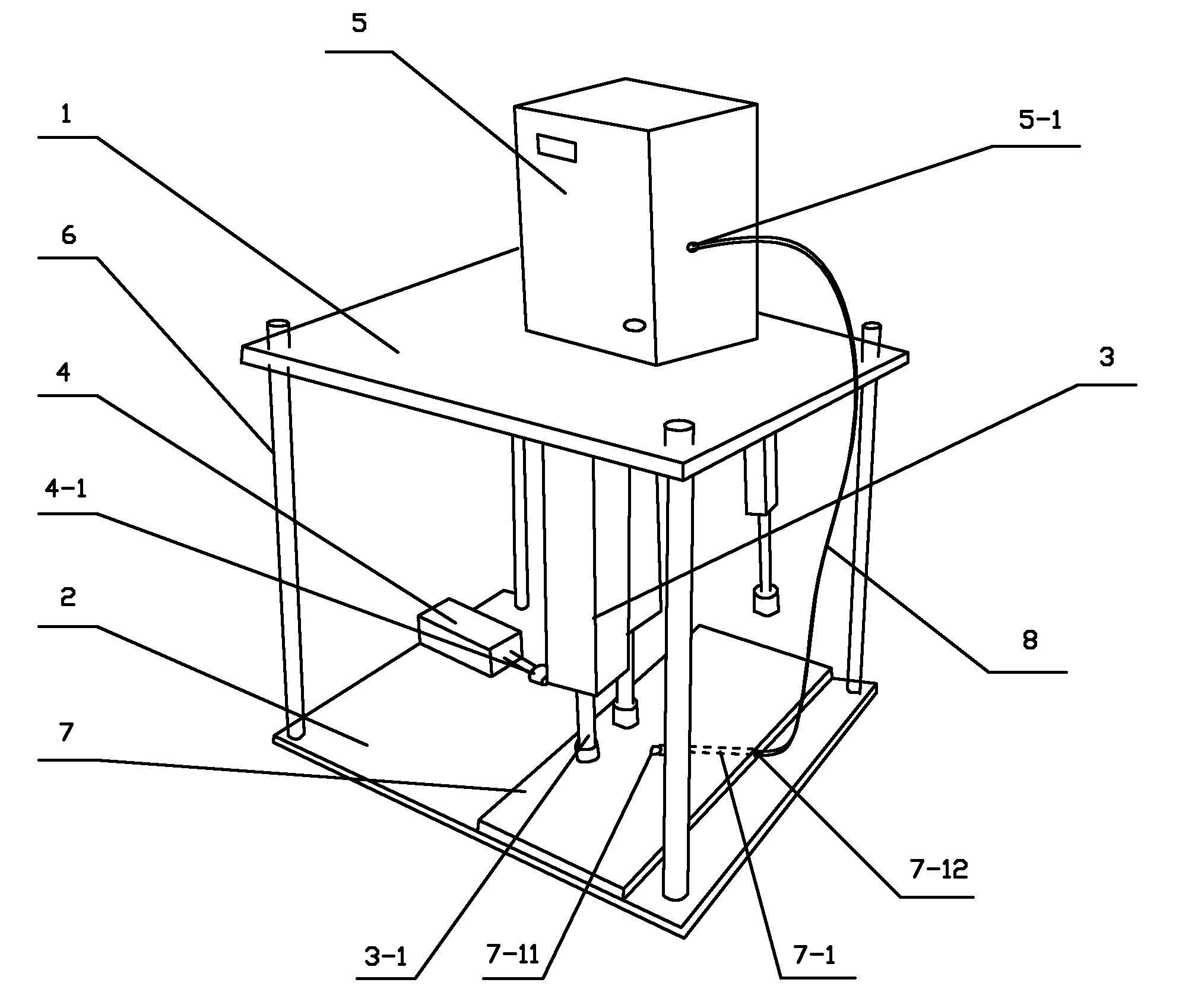

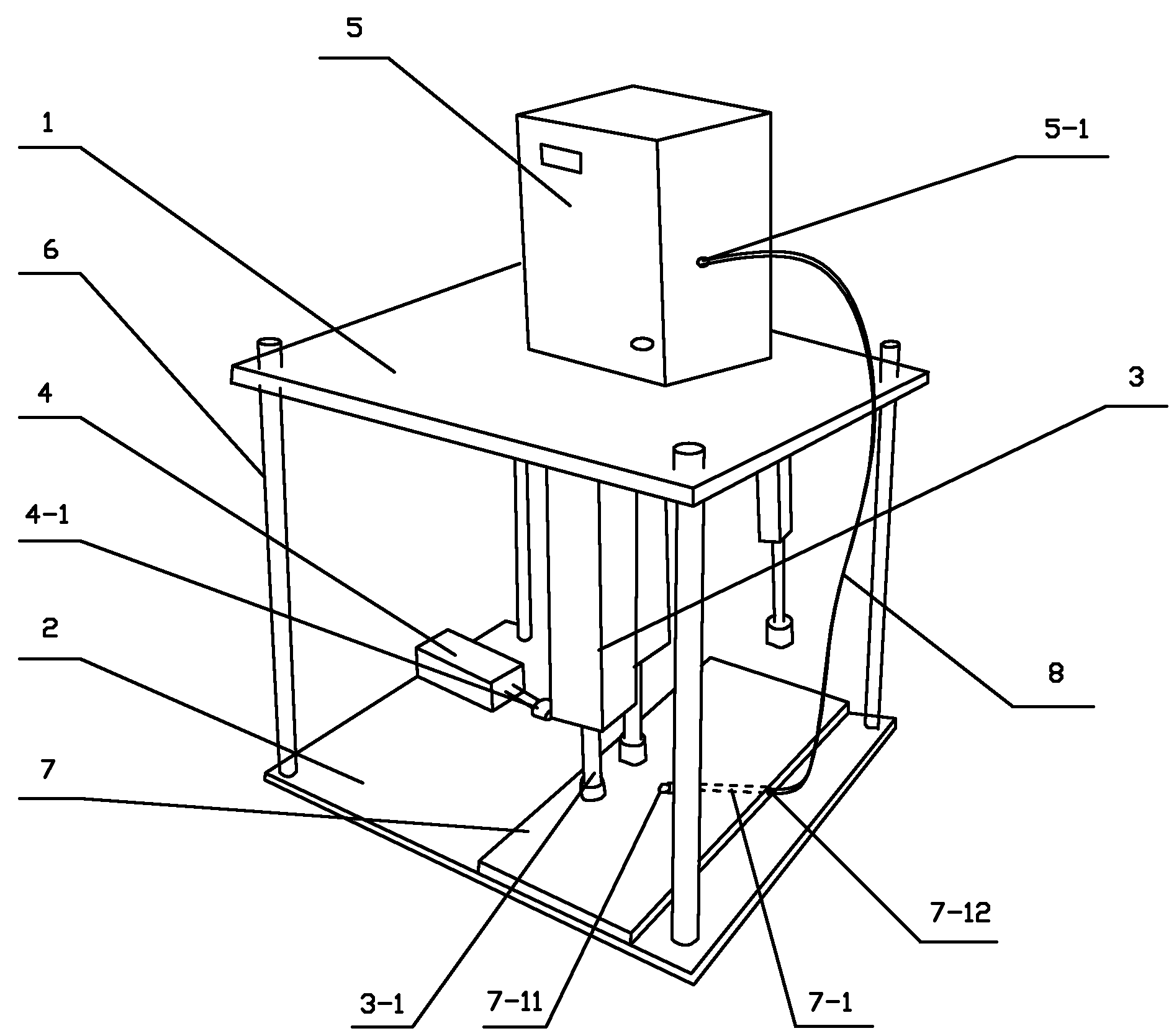

[0008] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. It mainly includes an upper workbench 1, a lower workbench 2, a longitudinal cylinder 3, a transverse cylinder 4 and an airtight leak detector 5. The upper workbench is connected with the lower workbench through four fixing columns 6 to form a three-dimensional support. The air-tight leak detector is set on the upper part of the upper workbench. The air-tight leak detector is the FL-296 type air-tight leak detector produced by Nagano Fukuda (Tianjin) Instrument Co., Ltd., which is suitable for the small pressure drop test range of 1 to 999Pa. Range, the air inlet of the airtight leak detector is connected to the exhaust port of the air compressor through the air pipe, and the air outlet of the airtight leak detector is connected to the air hole on the bottom plate through the air pipe, the air pipe is equip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com