Technological method for removing base metals in rhodium/iridium secondary replacement residues

A technology of secondary replacement and process method, applied in the direction of improving process efficiency, etc., can solve the problems of large dispersion of precious metal rhodium iridium, low leaching rate of base metals, etc., achieve low base metal content, increase leaching rate, and reduce dispersion loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

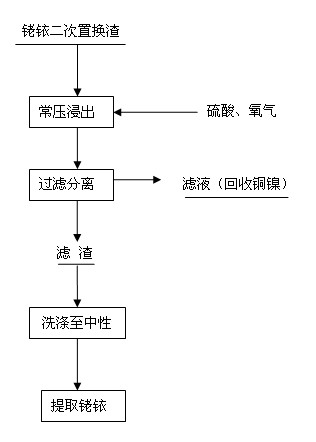

Method used

Image

Examples

Embodiment 1

[0018] (1) Put 400g of rhodium-iridium secondary replacement slag, add water and sulfuric acid, make the liquid volume 3200L according to the solid-liquid ratio of 1:8, and make the acidity of the solution 2mol / L;

[0019] (2) Stir and heat up, and when the temperature rises to 80°C, oxygen is introduced to carry out the leaching reaction. During the reaction, the temperature is controlled between 80°C and 85°C, and the oxygen flow rate is controlled at 0.6m 3 / h, filter after reacting for 30h;

[0020] (3) The filter residue was washed to neutral, and the leaching rate of the base metal was 90.4%, and the rhodium-iridium and other precious metals were enriched by 8 times for the rhodium-iridium secondary replacement residue.

[0021] Through this method, the slag is replaced twice.

Embodiment 2

[0023] (1) Put 420g of rhodium-iridium secondary replacement slag, add water and sulfuric acid, make the liquid volume 4200L according to the solid-liquid ratio of 1:10, and make the acidity of the solution 3mol / L;

[0024] (2) Stir and heat up, and when the temperature rises to 80°C, oxygen is introduced to carry out the leaching reaction. During the reaction, the temperature is controlled between 80°C and 85°C, and the oxygen flow rate is controlled at 0.8m 3 / h, filter after reacting for 40h;

[0025] (3) The filter residue was washed to neutral, and the leaching rate of base metals in the secondary replacement residue was 90.4%, and the enrichment of rhodium, iridium and other precious metals was 8 times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com