Method for preparing chitin

A technology of chitin and chitin, which is applied in the field of comprehensive utilization of waste water in the process of food and pharmaceutical processing, can solve the problems of large amount of waste water, pollute the environment, etc., and achieve the effect of reducing emissions and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

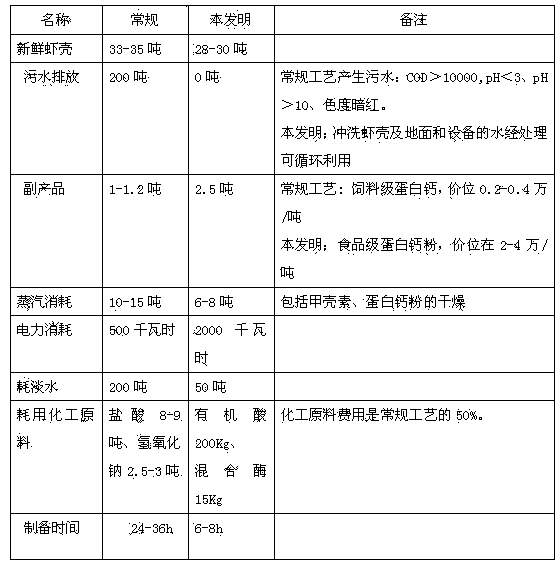

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing chitin from dried shrimp shells, the method comprises the following steps:

[0030] ① Crush 300Kg of dried shrimp shells (moisture ≤ 10%) to 5 meshes, suck it into a 3000L enamel reaction kettle (equipped with 6 ultrasonic probes, and the ultrasonic frequency is 40KHZ) with vacuum, add 2000Kg of deionized water at the same time, stir, and the speed is 50r / min.

[0031] ②Raise the temperature to 60°C, slowly add 60Kg of organic mixed acid, which consists of the following organic acids: lactic acid, formic acid, propionic acid, citric acid, malic acid, gluconic acid and a small amount of phytic acid. By weight percentage: 55% lactic acid, 8% formic acid, 12% propionic acid, 10.5% citric acid, 9.5% malic acid, 4.5% gluconic acid, 0.5% phytic acid.

[0032] ③ Adjust the rotation speed to 20r / min. After reacting for 30 minutes, cool down to 50°C and add 4.5Kg of mixed enzyme. The mixed enzyme is composed of the following enzymes: acid protease, papain...

Embodiment 2

[0039] A method for preparing chitin directly from fresh shrimp shells by wet method. In this method, the fresh shrimp shells are washed with fresh water (the amount of fresh water for washing is 0.5-2 times that of the shrimp shells), and the rinse water is passed through the grid sedimentation tank, and then passed through the grid into the Adsorption pool (sandstone, natural zeolite, activated carbon layer, chitosan resin layer), through the grid to the clear water pool (the water is reused). The washed shrimp shells are centrifuged, the shrimp shells are wet crushed or screw extruded into 3-10 meshes, the slurry is put into the reaction kettle, and deionized water is added according to 20%-50% of the slurry weight, and the following process refers to that of Example 1. method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com