Hard carbon coated lithium ion battery anode material and preparation method thereof

A lithium-ion battery and negative electrode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of low carbonization rate of resin, high volatile matter, poor affinity, etc., to improve the first Coulombic efficiency and comprehensive electrical performance , Improve the effect of cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

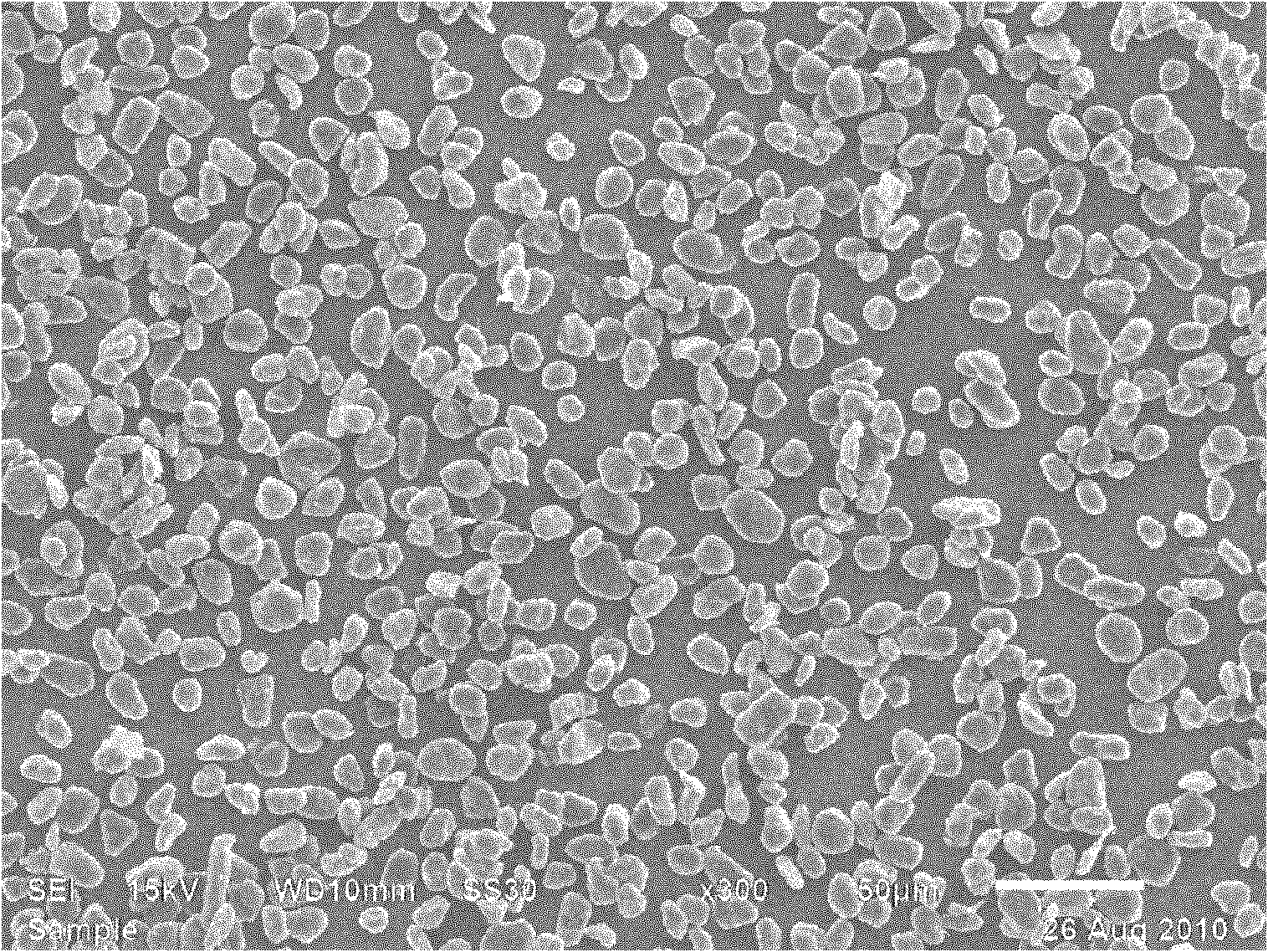

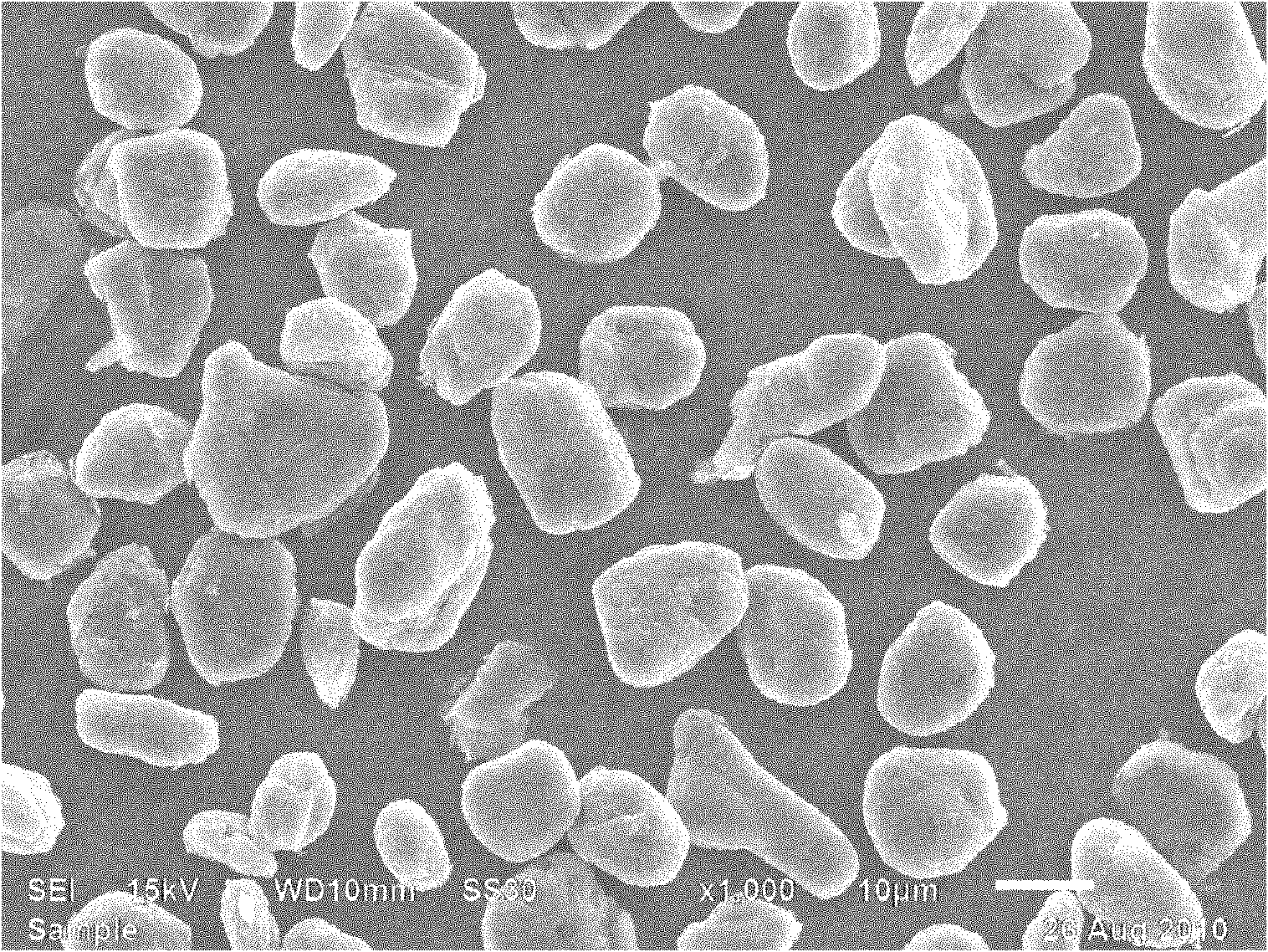

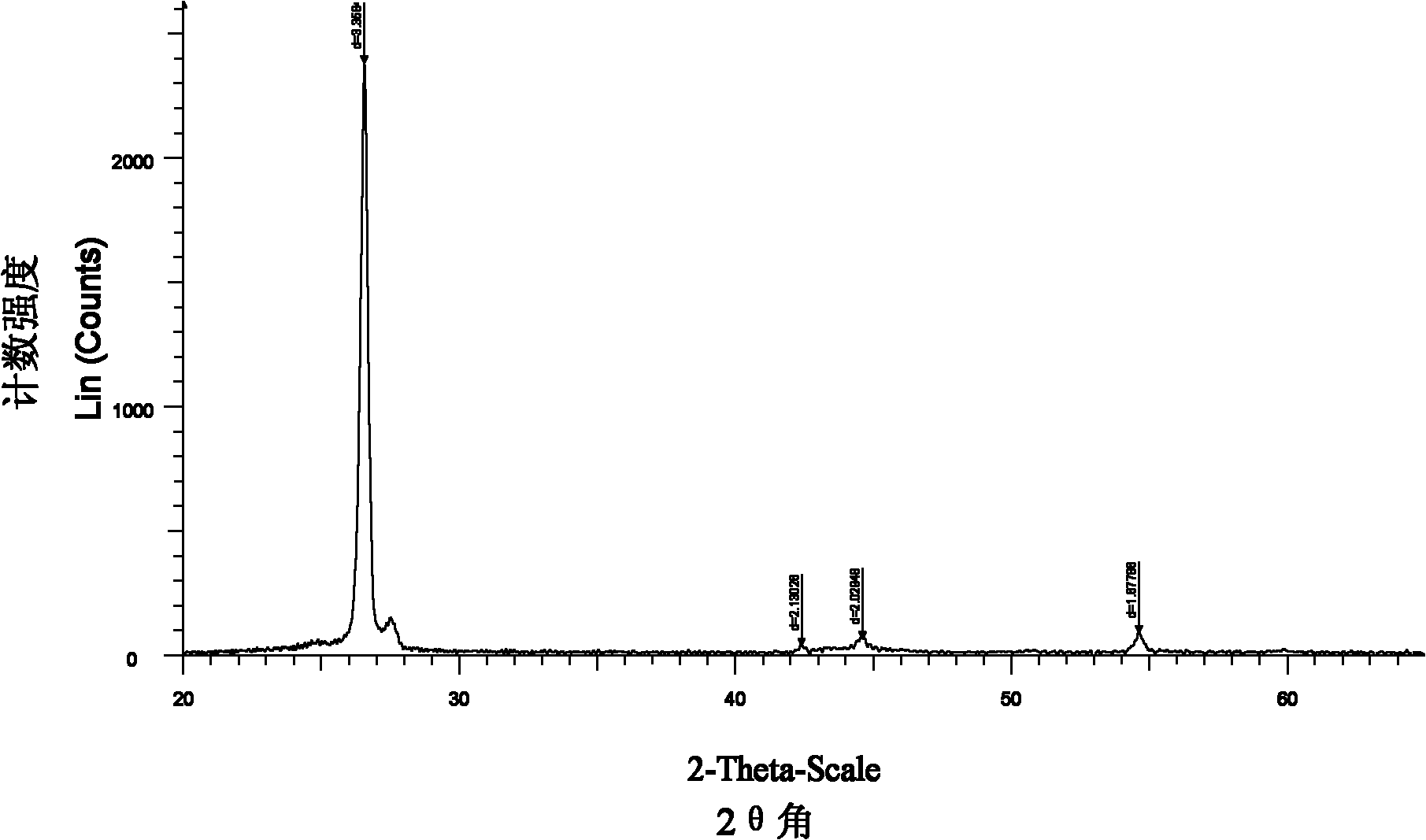

[0018] Weigh 10g of boric acid, 33g of heat-shrinkable phenolic resin, and 67g of asphalt into a mixing mixer, mix and stir for 1 hour at room temperature, add 890g of natural graphite micropowder with an average particle size of 18 μm and a degree of graphitization ≥ 80%, and continue stirring for 2 hours. Put it into a ceramic crucible and put it into a plate kiln. Under the protection of nitrogen atmosphere, raise it to 150°C at a rate of 1.5°C / min, keep it for 2 hours, then raise it to 1100°C at a rate of 2°C / min, keep it for 4 hours, and then cool it naturally to Take out the material below 200°C, crush and sieve, then raise the temperature to 2850°C at a rate of 3°C / min under the protection of nitrogen atmosphere, keep it warm for 3 hours, cool it down to below 200°C naturally, take out the material, crush and sieve it It is the anode material of lithium ion battery.

Embodiment 2

[0020] Weigh 10g of boric acid, 25g of epoxy resin, and 75g of asphalt into the mixing mixer, mix and stir for 1.5h at room temperature, add 890g of natural graphite powder with an average particle size of 18μm and a degree of graphitization ≥ 80%, continue stirring for 2h, and pack the mixture into Put it into a ceramic crucible and put it into a plate furnace, under the protection of nitrogen atmosphere, raise it to 180°C at a rate of 3°C / min, keep it for 2h, then raise it to 1100°C at a rate of 1.5°C / min, keep it for 4h and then cool it naturally to 200°C The material is taken out below ℃, and after crushing and screening, it is the negative electrode material of lithium ion battery.

Embodiment 3

[0022] Weigh 15g of boron trioxide, 50g of heat-shrinkable phenolic resin, and 50g of asphalt into the mixing mixer, mix and stir for 2.5 hours at room temperature, add 885g of natural graphite powder with an average particle size of 18μm and a degree of graphitization ≥ 80%, and continue stirring 2h, put the mixture into a ceramic crucible and put it into a plate kiln, under the protection of nitrogen atmosphere, raise it to 160°C at a rate of 2.5°C / min, keep it for 2h, then raise it to 1080°C at a rate of 2°C / min, and keep it for 4h , and then naturally cooled to below 200°C to take out the material, crushed and sieved, then heated up to 3000°C at a rate of 2.5°C / min under the protection of nitrogen atmosphere, kept for 5 hours and then naturally cooled to below 200°C to take out the material, crushed , After sieving, it is the negative electrode material of lithium ion battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com