Method for simulating three-dimensional light intensity distribution of thick photoresist backside oblique incidence photoetching process

A technology of thick photoresist and light intensity distribution, used in microlithography exposure equipment, photolithography exposure devices, special data processing applications, etc., can solve the problem of inability to simulate three-dimensional light intensity distribution, and achieve high simulation accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

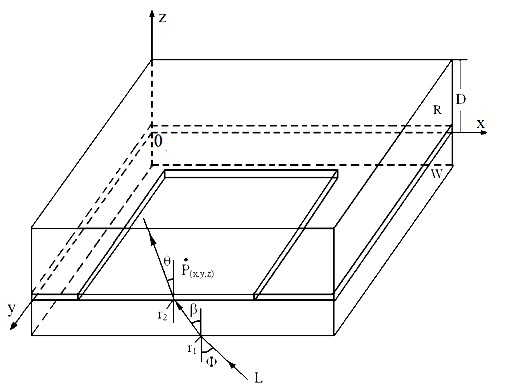

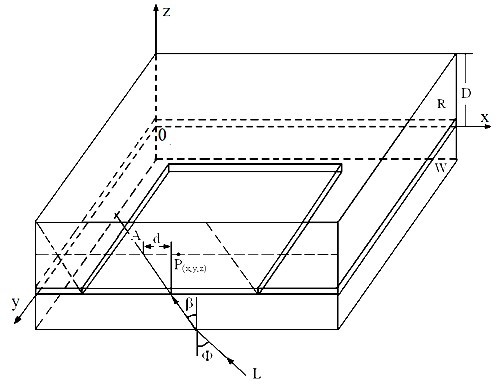

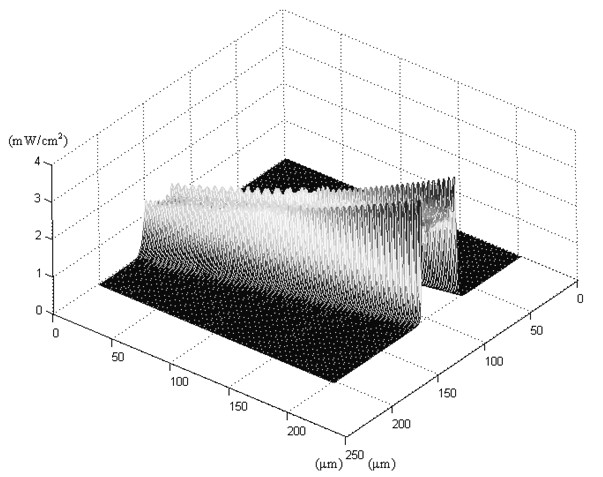

[0016] Based on the theory of scalar diffraction, the invention adopts the paraxial approximation technology of oblique incidence of ultraviolet light to process and simplify the Fresnel-Kirchhoff diffraction integral equation. At the same time, the reflection and refraction effects at the air / reticle and reticle / SU-8 adhesive interfaces during the propagation of ultraviolet light, as well as the absorption of ultraviolet light by SU-8 adhesive, were considered. It can quickly and accurately simulate the three-dimensional light intensity distribution inside the SU-8 glue during the oblique incident backside photolithography process of SU-8 glue ultraviolet light. The basic steps of this method are as follows: (1) According to the photolithography process conditions and parameters, input the coordinates A of the four boundary vertices of the mask hole 1(x1,y1,0) 、A 2(x1,y2,0) 、A 3(x2,y1,0) and A 4(x2,y2,0) , the incident angle Φ of obliquely incident ultraviolet light in air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com