Elementary cell automation machine coupling method for thin film boundary and deposition rate calculation

A cellular automaton and deposition rate technology, applied in chemical instruments and methods, membrane technology, electrical components, etc., can solve the problem of reducing the simulation speed, affecting the simulation accuracy, unable to meet the simulation accuracy and speed requirements of MEMS and IC processes, etc. problem, to achieve fast simulation speed, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

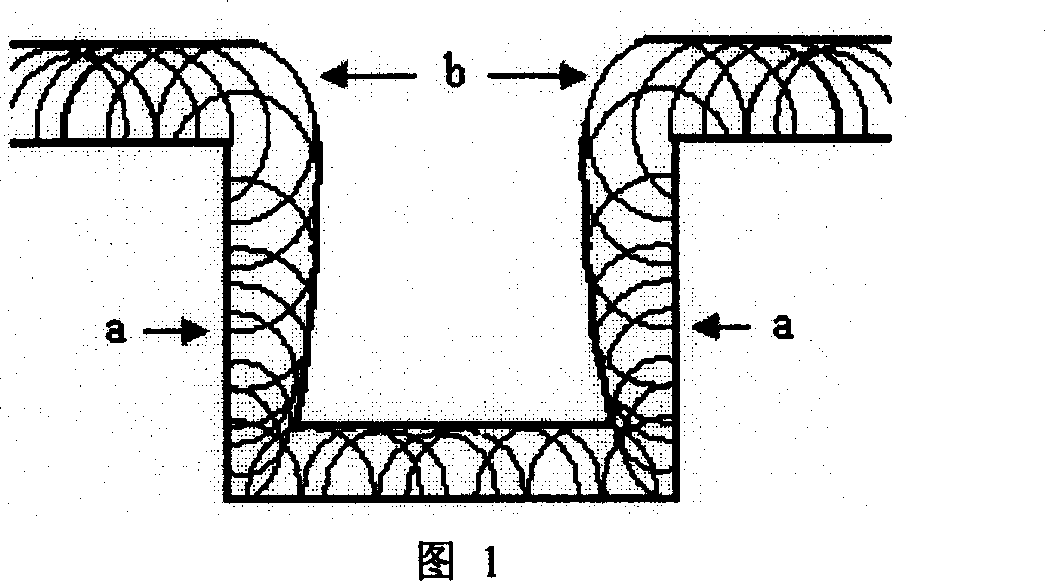

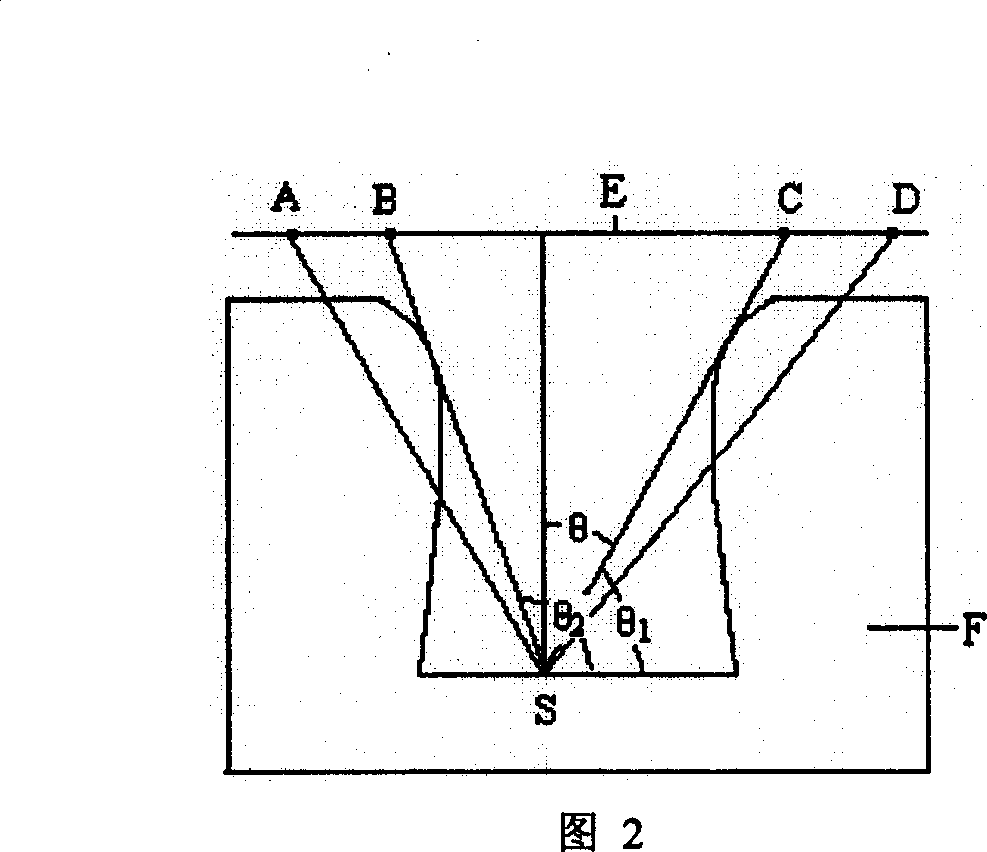

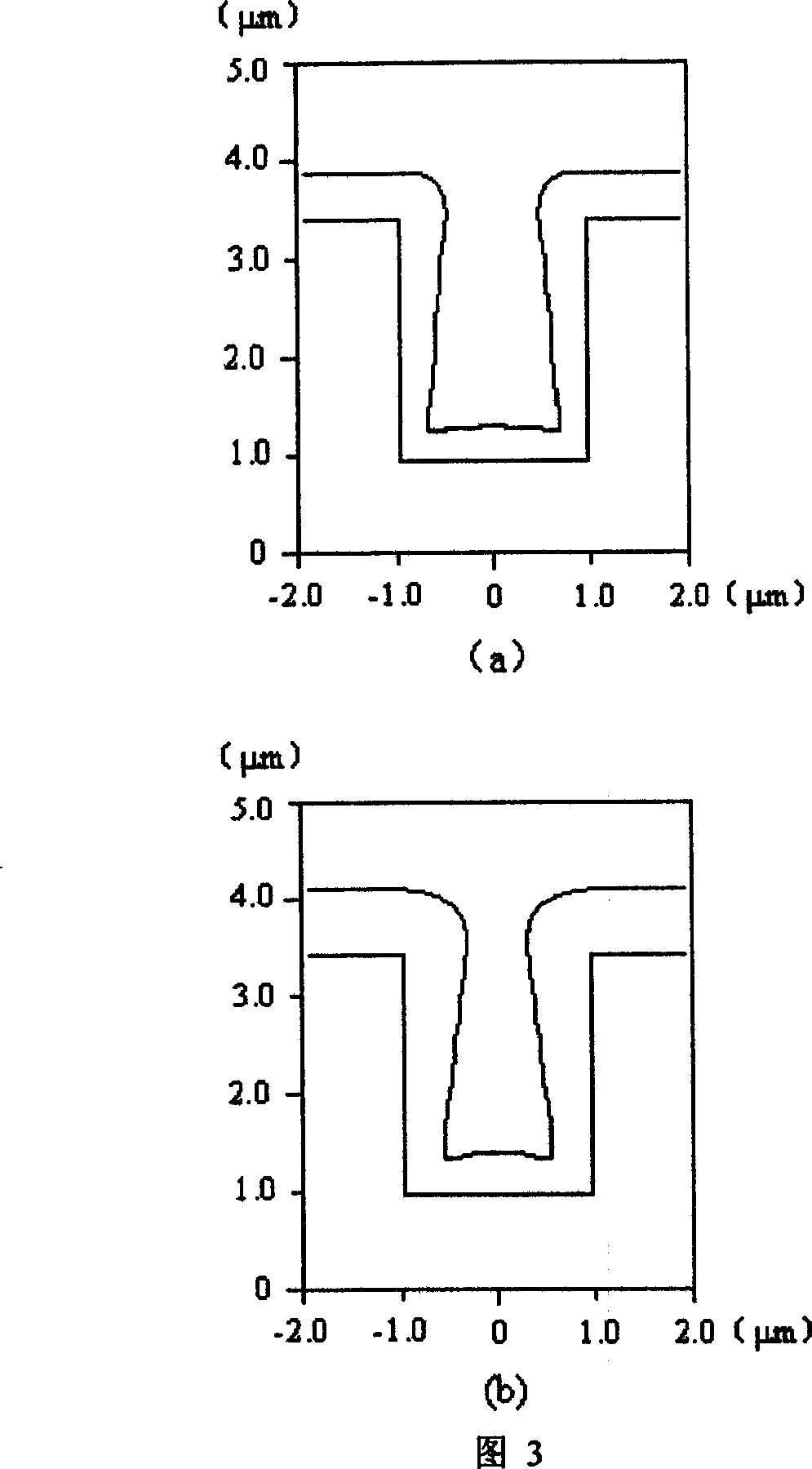

[0023] In the present invention, the cellular automaton adopts the two-dimensional Moore neighborhood, and utilizes the corresponding two-dimensional matrix to simulate the deposition process. Subdivide the substrate into an array of small squares with a side length a, and each square serves as a cell of CA. At a certain time t, the state C of the cell i,j (t) is defined as the area A of the deposited material in the cell at this time in (t) and the whole cell area A t The ratio of:

[0024] C i , j ( t ) = A in ( t ) A t - - - ( 1 )

[0025] In the film deposition simulation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com