Method for removing impurities from large-particle metallurgical silicon material

A technology for metal impurities and metallurgical silicon, which is applied in the field of removing metal impurities from large-particle metallurgical silicon materials, can solve the problems of secondary pollution of the surface of silicon materials, dust cannot be used for subsequent processes, excessive oxidation, etc., and achieves good metal impurities removal effect. , the effect of reducing energy consumption and avoiding dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

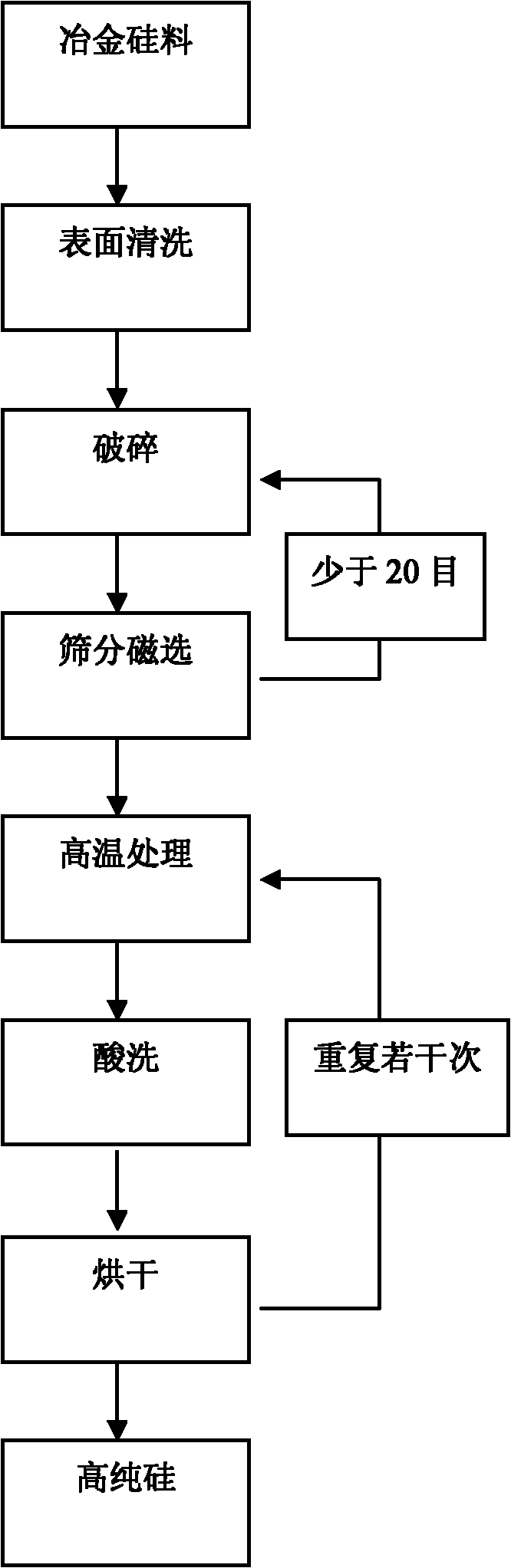

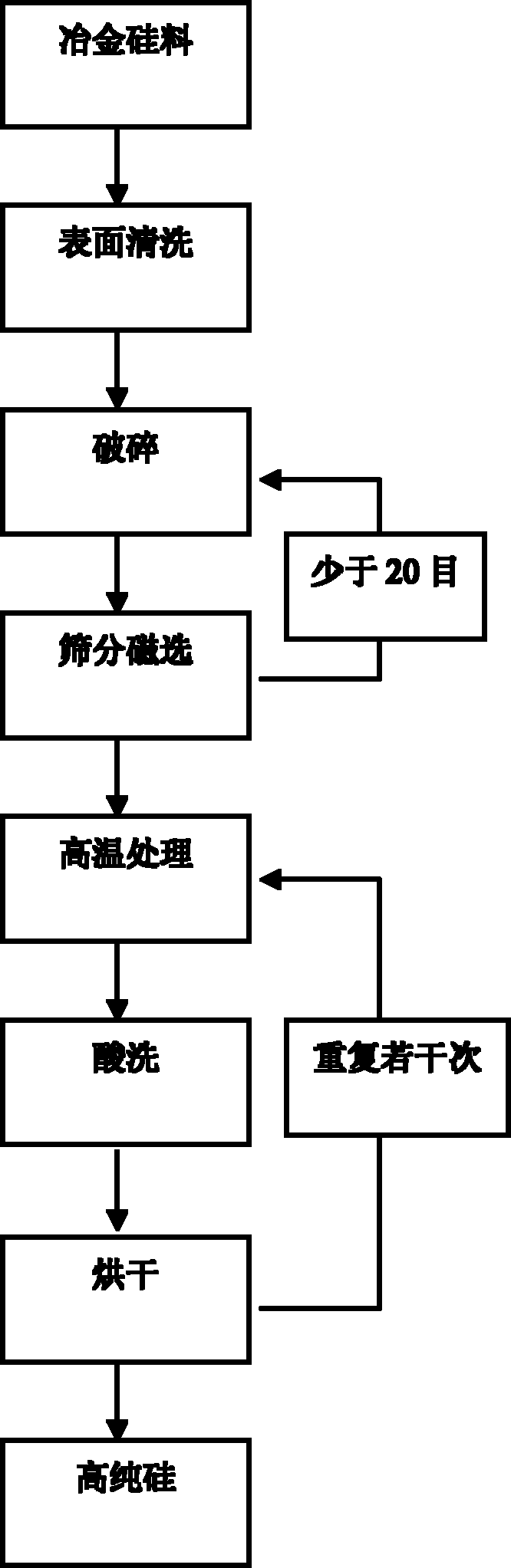

Image

Examples

Embodiment 1

[0023] HNO first 3 Wash the silicon material with a mixed acid of HF for 1-2 minutes, and then ultrasonically clean the silicon material with deionized water with a resistivity greater than 7MΩ·cm for 10-20 minutes to remove impurities on the surface of the silicon material, among which HNO in the mixed acid 3 The mole fraction of HF acid is 15-50%, and the mole fraction of HF acid is 1-5%. Then, the surface-cleaned silicon material is crushed and screened. The process of crushing and screening is to blast the metallurgical silicon water and put it into a pulverizer (including a ball mill and an electromagnetic separator inside) to pulverize for 2-3 times, and then use a sieve to screen out the particles. The diameter is 20-50 mesh powder. The silicon material whose particle size does not meet the requirements is crushed and screened again until the particle size of the silicon material meets the requirements. The metallurgical silicon material with a particle size of 20 mes...

Embodiment 2

[0029] Screen 30 mesh metallurgical silicon materials, and the test results of the silicon materials are as follows:

[0030] Fe(ppm)

Al(ppm)

Ca(ppm)

Cu(ppm)

Ni(ppm)

B(ppm)

P (ppm)

835.2

248.04

408.83

3.5

132

2.8

2.2

[0031] Clean the silicon material with pure water for 1min in the ultrasonic tank, dry it and put it into a high temperature furnace for heat treatment, at 50kPaAr50vol.%+N 2 Raise the temperature to 1150°C in a 50vol.% atmosphere, keep at this temperature for 10 hours, and then carry out acid leaching treatment at normal temperature and pressure after natural cooling. The mole fractions of each acid in the acid leaching agent are HF: 20%, HCl: 4%, HNO 3 : 0, the weight ratio of silicon material to acid leaching agent is 1:2, the acid leaching time is 10h, repeat the above operation 3 times, then wash and dry and send samples for testing.

[0032] The ICP-AES test results are as follow...

Embodiment 3

[0035] Screening 40 mesh metallurgical silicon materials, the implementation results:

[0036] Fe(ppm)

Al(ppm)

Ca(ppm)

Cu(ppm)

Ni(ppm)

B(ppm)

P (ppm)

427.8

96.4

419.57

4.9

34.3

6.8

40.9

[0037] Wash the silicon material with pure water in the ultrasonic tank for 1min, dry it and put it into a high-temperature furnace for heat treatment, heat it up to 1200°C in a 20kPa Ar atmosphere, keep it at this temperature for 15 hours, cool it naturally to normal temperature and pressure, and then carry out acid leaching treatment , the molar fractions of each acid in the acid leaching agent are HF: 40%, HCl: 4%: HNO 3 : 1%, the weight ratio of silicon material and acid leaching agent is 1:3, the acid leaching time is 36h, repeat the above operation 3 times, and then wash and dry.

[0038] The ICP-AES test results are as follows:

[0039] Fe(ppm)

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com