Impact dynamic tension test method and device thereof of ring laser

A laser shock and tensile test technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of complex loading method, many influencing factors, low strain rate, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

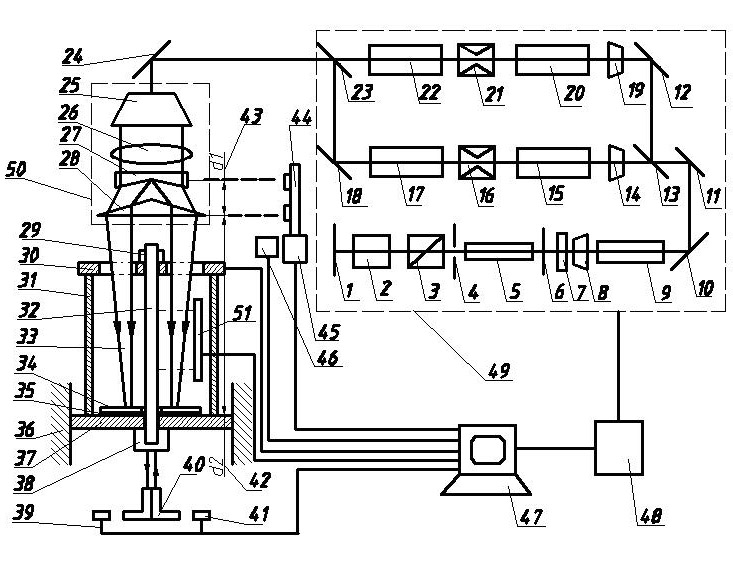

[0029] Combine below figure 1 Describe in detail the details and working conditions of the specific device proposed by the present invention.

[0030] Such as figure 1 As shown, the described a kind of laser shock dynamic tensile test device includes: high-power pulsed laser 49, 45° total reflection mirror E24, spot adjustment device 50, spoke bracket 30, fixed distance support 31, clamp A29, clamp B38 , target material 37, optical glass sheet 34, guide rail A36, guide rail B44, absorbing layer 35, trigger 46, stepper motor 45, computer 47, laser power supply 48, stress sensor, optical extensometer 51, auxiliary displacement sensor; The high-power pulse laser 49 includes: total reflection mirror 1, KD*P crystal 2, polarizer 3, aperture stop 4, YAG crystal A5, YAG crystal B9, YAG crystal C15, YAG crystal D17, YAG crystal E20, YAG crystal F22, output mirror 6, isolator 7, beam expander A8, beam expander B14, beam expander C19, 45° total reflection mirror A10, 45° total reflect...

PUM

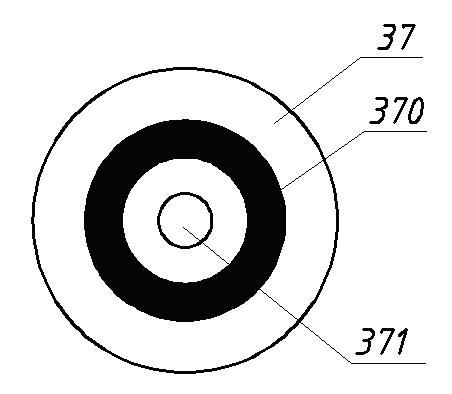

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com