Titanium-based amorphous alloy and preparation method thereof

An amorphous alloy and titanium-based technology, which is applied in the field of amorphous alloys and their preparation, can solve the problem that titanium-based amorphous alloys cannot be harmless to the human body, and achieve the best bending plasticity, large critical size, and wide preparation conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This example is used to illustrate the preparation of the titanium-based amorphous alloy provided by the present invention.

[0030] A total of 50 grams of raw materials Ti, Cu, Ag, and Sc were put into a vacuum induction furnace according to a certain ratio, evacuated to 50 Pa, and then filled with argon (the purity of argon is 99% by volume), at about 2000 ° C , smelting for 2 minutes to fully melt the alloy raw material, and then remelt 3 times to fully alloy it;

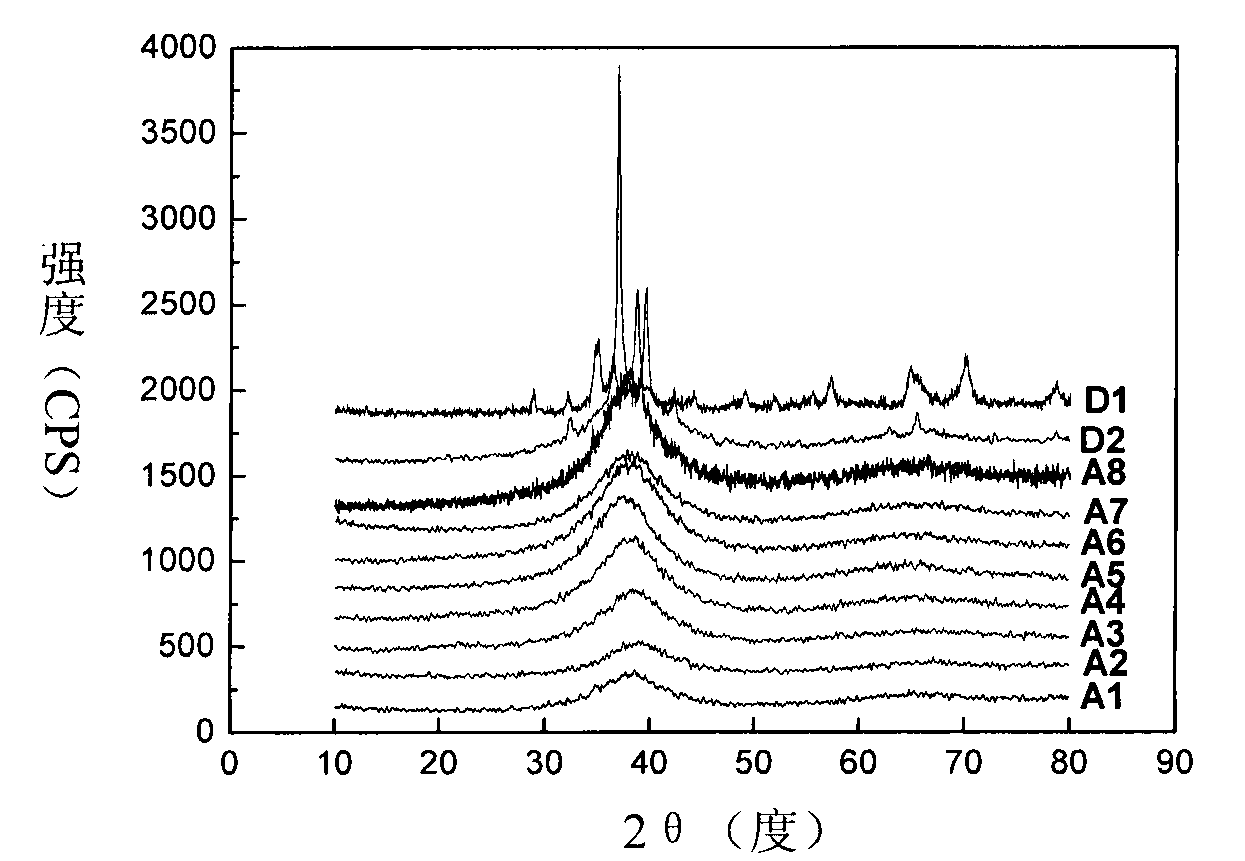

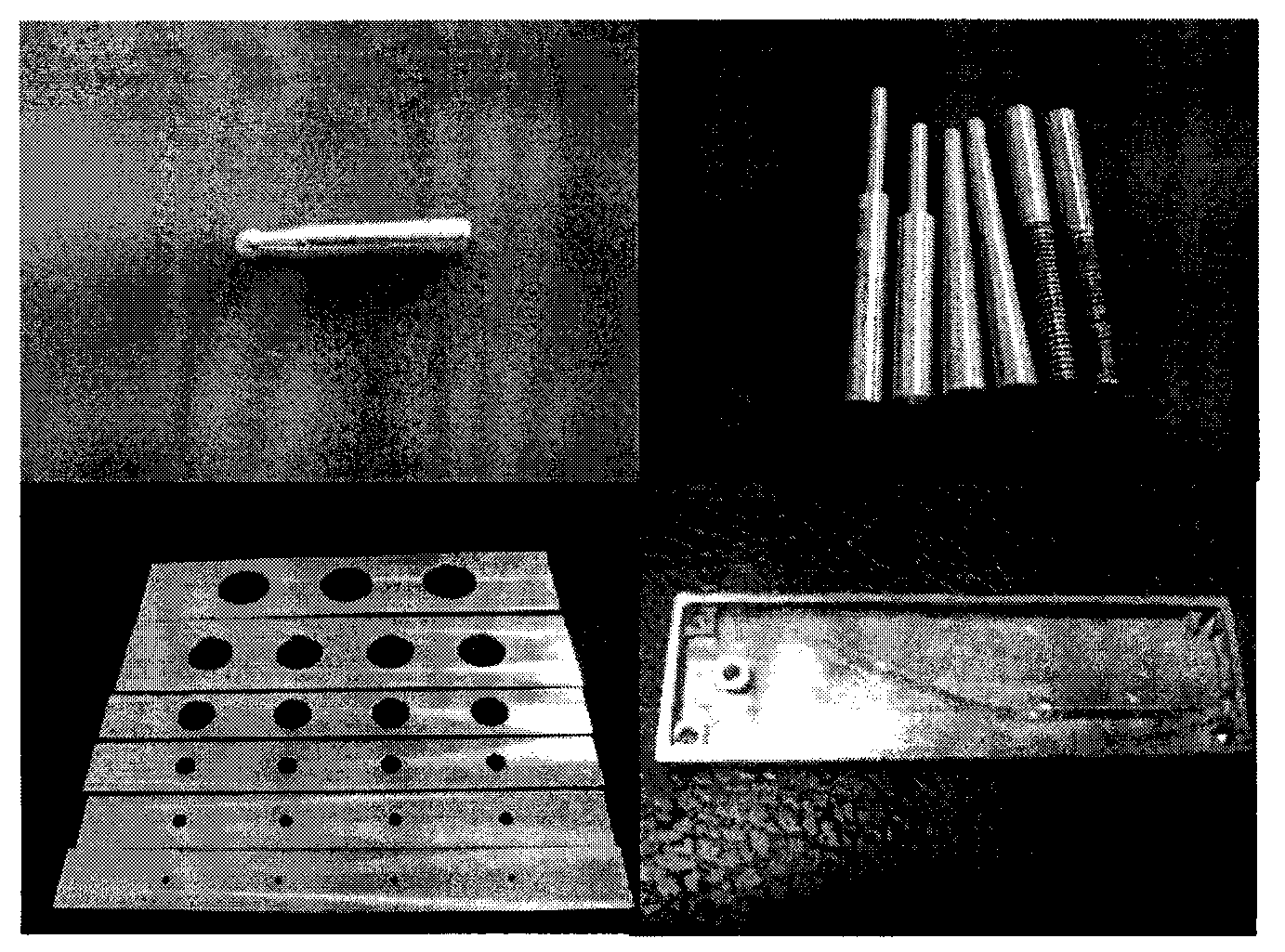

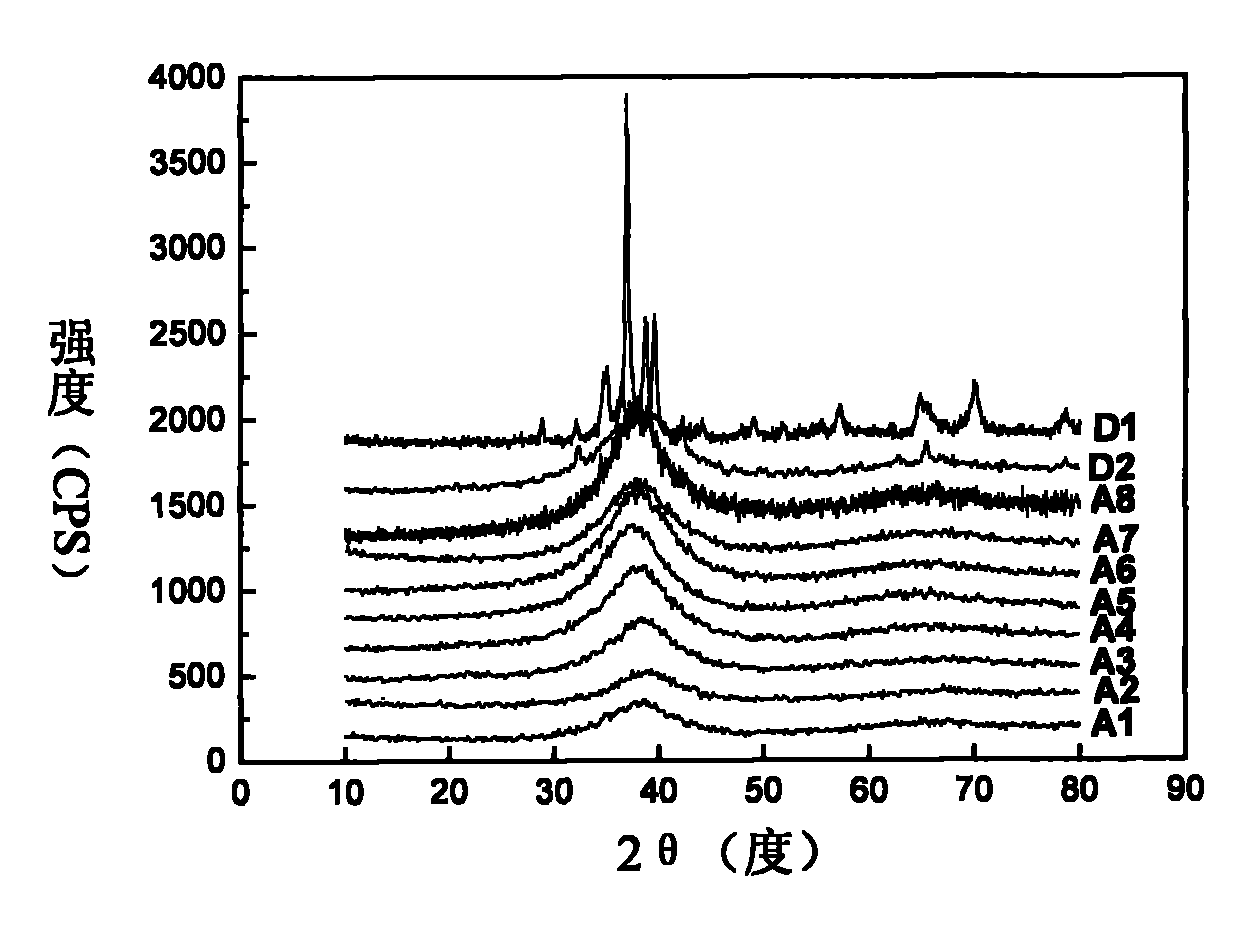

[0031] Then the molten alloy sample is cast into a metal mold by high-pressure casting (wherein, pressure 20MPa, mold material SKD61) cooling molding (cooling speed is 102K / s), and the obtained size is 100 mm long * 10 mm wide * high 3 mm bulk Ti-based amorphous alloy sample Al. The mass fraction of elements contained in the alloy was analyzed by inductively coupled plasma emission spectroscopy (ICP-AES), and converted into atomic percentage, it can be known that the composition of the bulk titanium-based...

Embodiment 2

[0033] This example is used to illustrate the preparation of the titanium-based amorphous alloy provided by the present invention.

[0034] Prepare a titanium-based amorphous alloy according to the method in Example 1, except that the raw materials are Ti, Cu, Sn, Fe, Y, and obtain a large titanium-based amorphous alloy with a size of 100 mm long × 10 mm wide × 3 mm high Alloy sample A2. The mass fraction of the elements contained in the alloy is analyzed by inductively coupled plasma emission spectroscopy (ICP-AES), and converted into atomic percentage, it can be known that the composition of the bulk titanium-based amorphous alloy sample A2 is Ti 45 Cu 45 sn 4 Fe 5 Y 1 (Wherein, the total atomic percent of metallic impurity elements and the total atomic percent of nonmetallic impurity elements are 1% and 0.1%, respectively).

Embodiment 3

[0036] This example is used to illustrate the preparation of the titanium-based amorphous alloy provided by the present invention.

[0037] Prepare a titanium-based amorphous alloy according to the method of Example 1, except that the raw materials are Ti, Cu, Sn, Ag, Y, Sc, and obtain a large titanium-based alloy with a size of 100 mm long × 10 mm wide × 3 mm high Amorphous alloy sample A3. The mass fraction of the elements contained in the alloy is analyzed by inductively coupled plasma emission spectroscopy (ICP-AES), and converted into atomic percentage, it can be known that the composition of the bulk titanium-based amorphous alloy sample A3 is Ti 49 Cu 43 sn 3 Ag 3 Y 1 sc 1 (Wherein, the total atomic percent of metallic impurity elements and the total atomic percent of nonmetallic impurity elements are 2% and 0.15%, respectively).

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical dimension | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| critical dimension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com