Method for extracting grease from wet alga mud by using mixed organic solvent

A technology of organic solvents and mixed solvents, applied in the direction of fat oil/fat production and fat production, can solve the problems of large amount of alcohol, low solubility, low solubility, etc., to save drying energy consumption, high oil extraction rate, simple separation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

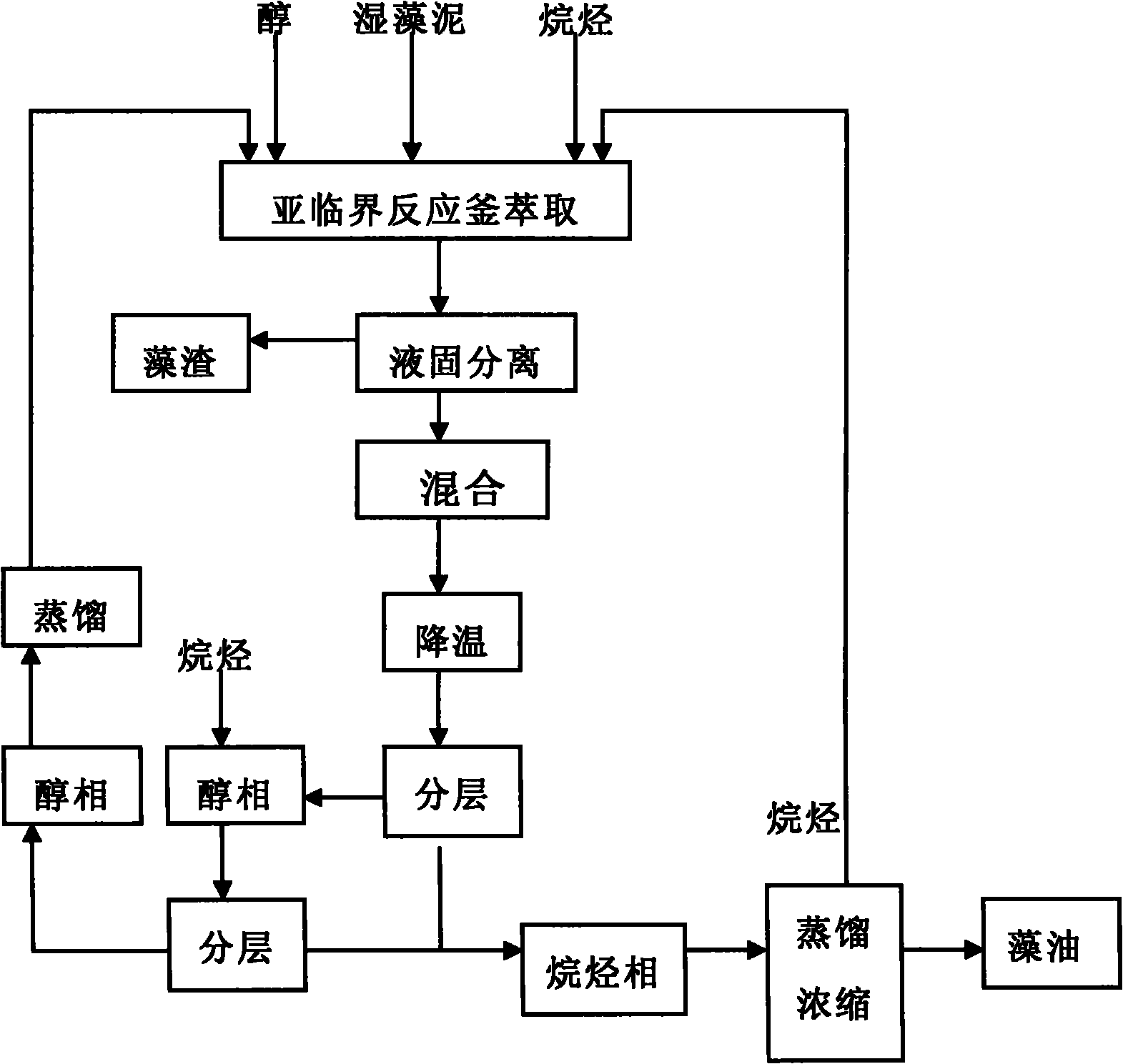

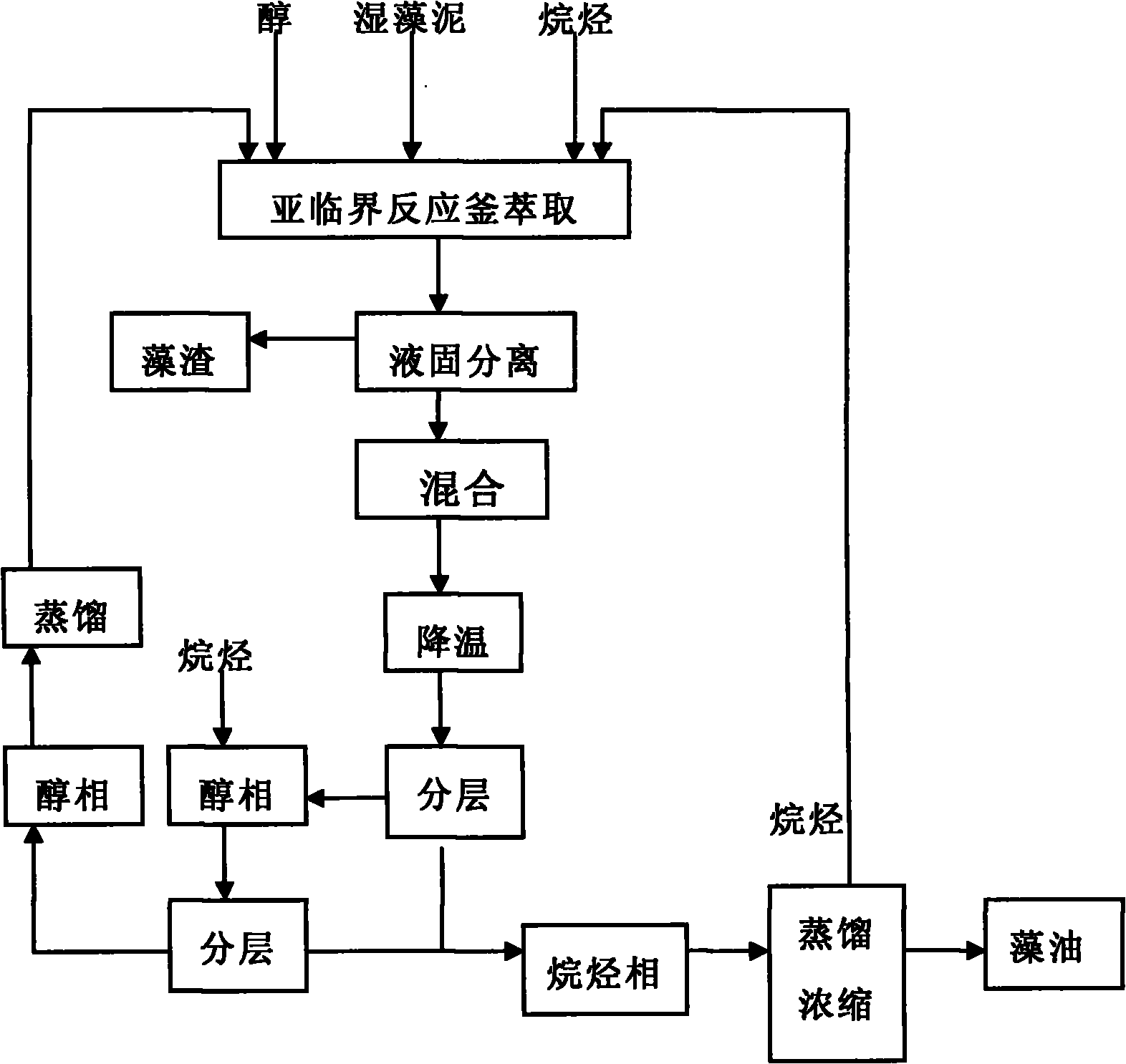

Method used

Image

Examples

Embodiment 1

[0027] Take Nannochloropsis wet algal mud 100g (water content 60%, initial total lipid content 33.4%), add the mixed liquid of the analysis pure ethanol (ethanol content 99%) of 400ml and normal hexane (both volume ratios are 1 / 6), be placed in the stainless steel pressure reaction kettle and seal, pass into N in the reaction kettle 2 Heat to 1.5MPa, heat to 110°C and maintain the reaction for 1 hour, then take out the algae pulp, centrifuge at 6500rpm for 10min, remove the microalgae cell residue, let the supernatant stand, separate the upper n-hexane phase, and use 60ml n-hexane for the ethanol phase Extracted twice, combined all n-hexane phases, concentrated by rotary evaporation, and dried to obtain 11.2 g of algae oil, with a total lipid extraction rate of 83.8%.

Embodiment 2

[0029] Take Nannochloropsis wet algae mud 100g (water content 60%, initial total fat content 33.4%), add the mixed liquid of the industrial ethanol (ethanol content 85%) of 400ml and normal hexane (both volume ratios are 1 / 3 ), placed in a high-pressure reactor and sealed, and passed into the reactor with N 2 Heat to 1.5MPa, heat to 110°C and react for 1 hour, then take out the algae slurry, centrifuge at 6500rpm for 10min, remove the microalgae cell residue, let the supernatant stand, separate the upper layer of n-hexane phase, and extract the ethanol phase with 100ml of n-hexane Once, all n-hexane phases were combined, concentrated by rotary evaporation, and dried to obtain 8.68 g of algae oil, with a total lipid extraction rate of 65%.

Embodiment 3

[0031] Weigh 100g of Nannochloropsis wet algae mud (water content 60%, initial total lipid content 33.4%), add 320ml of analytical pure ethanol and n-hexane mixed liquid (the volume ratio of the two is 1 / 5), and place under high pressure The reactor was sealed, and N was introduced into the reactor. 2 Heat to 1.5MPa, heat to 100°C and react for 1 hour, then take out the algae pulp, centrifuge at 6500rpm for 10min, remove the microalgae cell residue, let the supernatant stand, separate the upper n-hexane phase, and extract the ethanol phase with 60ml of n-hexane Twice, all n-hexane phases were combined, concentrated by rotary evaporation, and dried to obtain 10.69 g of algae oil, with a total lipid extraction rate of 80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com