Method for recovering and recycling silicon slice cutting waste mortar

A silicon chip cutting and waste mortar technology, applied in the direction of lubricating composition, etc., can solve the problems of sewage COD increase, long maintenance time, high production cost, etc., and achieve the effect of reducing COD content, reducing labor intensity and reducing maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

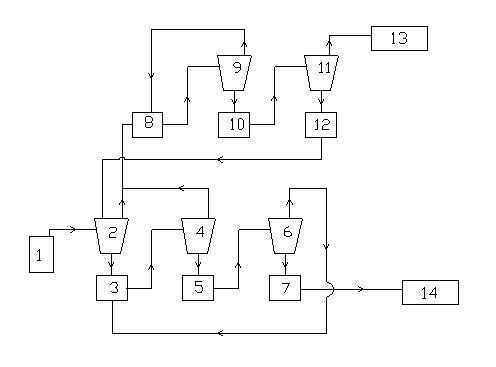

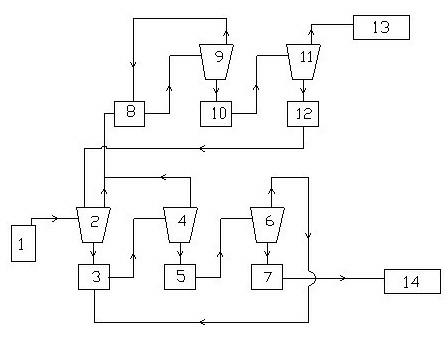

Image

Examples

Embodiment 1

[0023] The invention relates to a method for recycling waste mortar for cutting silicon wafers, said method comprising the following process steps:

[0024] Step 1. Preprocessing:

[0025] Mortar mixing, according to the ratio of raw pulp and water 1:0.35~0.55 for effective and uniform stirring, and at the same time, use steam to heat the mortar to 50-60°C; then use a plate and frame filter press for solid-liquid separation;

[0026] Step 2, recovery of PEG:

[0027] Add a decolorizer to the filtered liquid, and heat the liquid at the same time. The temperature is controlled at 55-65°C, stirred for 35-45 minutes, and then plate and frame filtered. The obtained filtrate is exchanged with an ion exchange resin; The exchanged liquid undergoes multi-effect distillation to reduce the moisture in the liquid to 15-20%, then undergoes vacuum distillation to control the moisture below 5%, and then undergoes rectification to control the moisture below 0.5%, and finally uses the filter ...

Embodiment 2

[0033] As a preferred version of the present invention, the difference from Example 1 is:

[0034] In step 1, effective and uniform stirring is carried out according to the ratio of raw pulp to water 1:0.45, and at the same time, the mortar is heated to 55°C with steam; and then the solid-liquid separation is carried out by using a plate and frame filter press;

[0035] Step 2, recovery of PEG:

[0036] Add a decolorizing agent to the filtered liquid, the added decolorizing agent is made of activated carbon accounting for 0.5% of the total weight of the liquid and 0.3% clay, while heating the liquid, the temperature is controlled at 60 ° C, stirred for 40 minutes, and then Carry out plate and frame filtration, and the obtained filtrate is exchanged by ion exchange resin; then the ion-exchanged liquid is subjected to multi-effect distillation to reduce the moisture in the liquid to 15-20%, and then the pressure is 0.09Mpa, and the temperature is 85°C. Under reduced pressure di...

Embodiment 3

[0038] The difference with embodiment 1 is:

[0039] In step 3, the separated solids are pickled again to remove metal oxides; Tandem settings.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com