Zero emission process of vanadium extraction wastewater

A zero-discharge, wastewater technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, inorganic chemistry, etc., can solve the problems of complex process, low treatment cost, occupation of equipment, etc., and achieve simple process operation. , the effect of improving the recovery rate and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

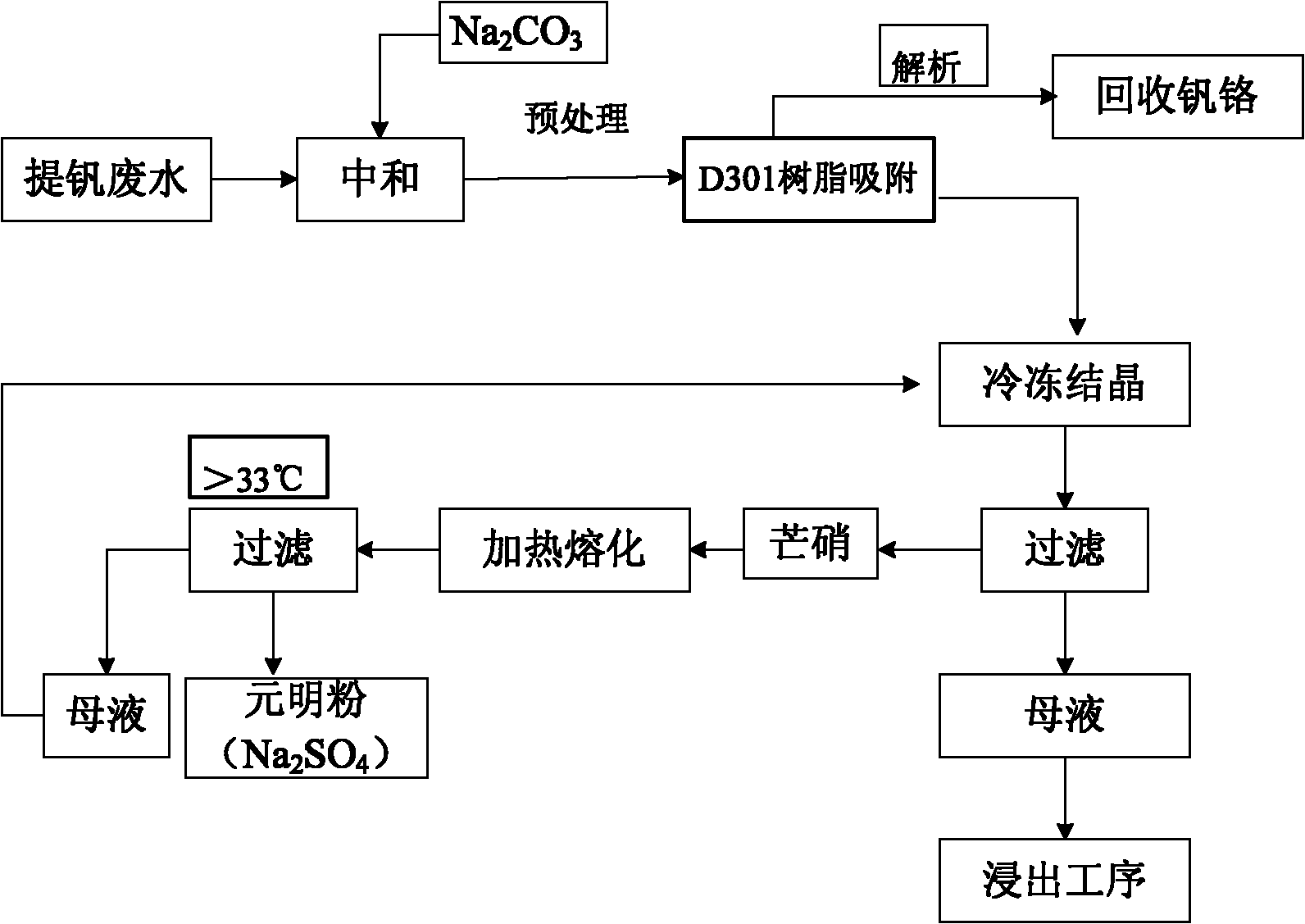

[0056] Get the vanadium extraction tail liquid 1L of Chengde No. 1 Vanadium Chemical Plant, its main chemical composition is shown in Table 2; Put into capacity and be in the volumetric flask of 5L, according to operating technique of the present invention, for example figure 1 The vanadium extraction waste water recycling process flow shown is for the treatment of the vanadium extraction tail liquid.

[0057] Table 2 Main chemical composition of vanadium extraction tail liquid (g / L)

[0058] V 5+ (mg / l

[0059] Table 3 National GB8978-1996 "Comprehensive Wastewater Discharge Standard" primary standard

[0060] V5+(mg / l)

[0061] As can be seen from the above table, the vanadium extraction wastewater is acidic, and the first pollutant V in the wastewater is 5+ 、Cr 6+ The content is relatively high, far higher than the maximum allowable discharge concentration of the first category of pollutants in the "Integrated Wastewater Discharge Standard", and the ...

Embodiment 2

[0066] Get the vanadium extraction tail liquid 1L of Chengde No. 1 vanadium chemical plant, its main chemical composition is shown in Table 5; Put into capacity and be in the volumetric flask of 5L, carry out the processing of extracting vanadium tail liquid according to the operation technique of the present invention, the composition after processing See Table 6

[0067] Table 5 Main chemical composition of vanadium extraction tail liquid (g / L)

[0068] V 5+ (mg / l

[0069] Table 6 Main chemical components after vanadium extraction tail liquid treatment

[0070] V 5+ (mg / l)

[0071] According to the measurement results, the suspended solids are all removed, the recovery rate of vanadium is 99.7%, and the recovery rate of chromium is 99.9%, which basically realizes the effective recovery of vanadium and chromium. After crystallization, the content of sodium salt in the tail liquid is greatly reduced, and the filtrate can be returned to leaching process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com