Brazing filler metal for brazing Al-Mg-Zn magnesium alloy

A technology of al-mg-zn and magnesium alloy, which is applied in the direction of welding/cutting medium/material, welding medium, welding equipment, etc., can solve the problems of high solder cost and high solder cost, and avoid oxidation and over-burning, Effect of good spreadability and gap filling properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

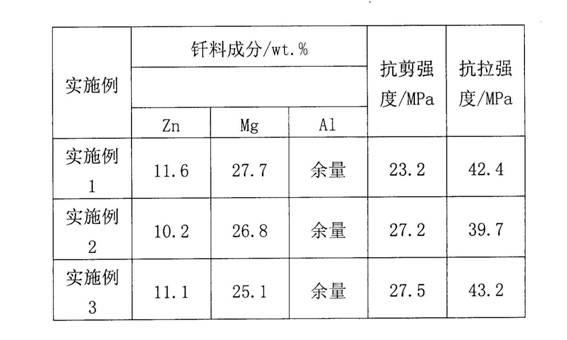

Embodiment 1

[0016] a. According to the chemical composition and mass percentage of the solder: Zn: 11.6%, Mg: 27.7%, and the balance is Al;

[0017] b. Use the flux protection method to smelt the solder alloy, pour it into ingots, and then use mechanical division to divide the solder into long strips.

[0018] When using the brazing filler metal of the present invention to braze AZ31B magnesium alloy, the AZ31B magnesium alloy sample is polished with sandpaper and cleaned with acetone to remove surface dirt before brazing. The flux is evenly spread, and the joint is fixed by a clamp and placed in an argon protection device for high-frequency induction brazing. During the brazing process, the argon flow rate is 0.3L / min, the heating rate is 200°C / min, and the brazing temperature range is 490-510°C. After holding for 100s, cool to room temperature. After brazing, the appearance of the joint was well formed, and the shear strength and tensile strength of the brazed joint were measured, and ...

Embodiment 2

[0020] a. According to the chemical composition and mass percentage of the solder: Zn: 10.2%, Mg: 26.8%, and the balance is Al;

[0021] b. Use the flux protection method to smelt the solder alloy, pour it into ingots, and then use mechanical division to divide the solder into long strips.

[0022] When using the brazing filler metal of the present invention to braze AZ31B magnesium alloy, the AZ31B magnesium alloy sample is polished with sandpaper and cleaned with acetone to remove surface dirt before brazing. The flux is evenly spread, and the joint is fixed by a clamp and placed in an argon protection device for high-frequency induction brazing. During the brazing process, the argon flow rate is 0.3L / min, the heating rate is 200°C / min, and the brazing temperature range is 490-510°C. After holding for 100s, cool to room temperature. After brazing, the appearance of the joint was well formed, and the shear strength and tensile strength of the brazed joint were measured, and ...

Embodiment 3

[0024] a. According to the chemical composition and mass percentage of the solder: Zn: 11.1%, Mg: 25.1%, and the balance is Al;

[0025] b. Use the flux protection method to smelt the solder alloy, pour it into ingots, and then use mechanical division to divide the solder into long strips;

[0026] When using the brazing filler metal of the present invention to braze AZ31B magnesium alloy, the AZ31B magnesium alloy sample is polished with sandpaper and cleaned with acetone to remove surface dirt before brazing. The flux is evenly spread, and the joint is fixed by a clamp and placed in an argon protection device for high-frequency induction brazing. During the brazing process, the argon gas flow rate was 0.3 L / min, the heating rate was 300 °C / min, and the brazing temperature range was 490-510 °C. After holding for 100 s, cool to room temperature. After brazing, the appearance of the joint was well formed, and the shear strength and tensile strength of the brazed joint were mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com