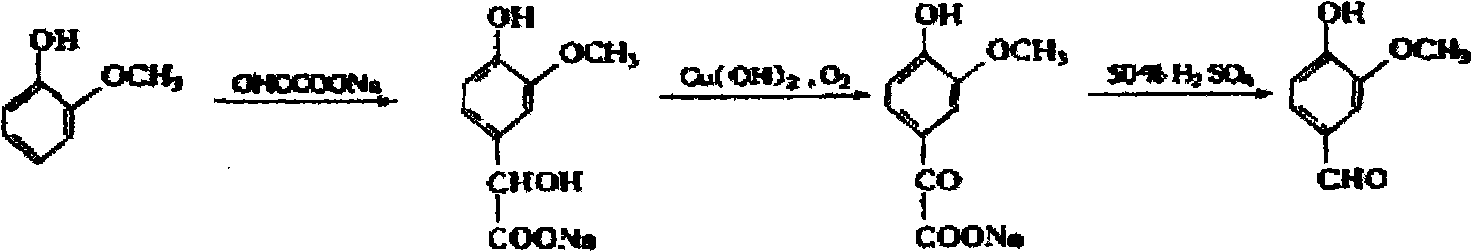

Catalyst for synthesizing vanillin by using a glyoxylic acid method and a one-pot method and preparation method thereof

A glyoxylic acid method and a catalyst technology are applied in the preparation of organic compounds, molecular sieve catalysts, carbon-based compounds, etc., which can solve the problem that the catalyst activity needs to be further improved, and achieve the inhibition of the formation of polymerization by-products, the high catalyst activity, and the preparation of The effect of the simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Catalyst preparation: Weigh 7.5g (0.03mol) of reagent copper sulfate and 2.4g (0.01mol) of reagent cobalt sulfate, and dissolve them in 100mL deionized water to prepare a metal salt solution. The rare earth Y-type molecular sieve (Re 2 o 3 ≥17%; SiO 2 / Al 2 o 3 ≥5;Na 2 O≤2%; loss on ignition ≥3%) 100g was added to the above metal salt solution and soaked for 30 minutes, then 5% sodium hydroxide solution was added dropwise to pH 11, the catalyst was separated by vacuum filtration, washed with a small amount of deionized water to remove sodium sulfate Salt, dry at 105°C, oxidize and roast in a high-temperature furnace at 550°C for 60 minutes, and set aside.

[0021] The catalyst is applied to the synthesis of vanillin: a 1000mL four-necked reaction flask equipped with an air distributor, a reflux condenser, a stirrer and three constant pressure dropping funnels is installed on a constant temperature water bath, and the three constant pressure dropping funnels 74.1g ...

Embodiment 2

[0023] Catalyst Preparation: The catalyst was prepared by the method in Example 1.

[0024] Catalyst is applied to the synthesis of ethyl vanillin: add 74.1g (0.4mol) 40% glyoxylic acid, 58.0g (0.42mol) ethyl guaiac respectively in the three constant pressure dropping funnels of embodiment 1 reactor Phenol and 100mL30% liquid caustic soda. Add 500 mL of deionized water and 106.6 g (0.8 mol) of 30% liquid caustic soda into the four-necked reaction flask, and add 5.0 g of the catalyst prepared by the method in Example 1, stir and blow in air, and the air pressure is 0.05 Mpa. After the solution was heated to 60°C, glyoxylic acid, ethyl guaiacol and alkali solution were added dropwise to the reaction bottle at the same time. The concentration of the 3-ethoxy-4-hydroxymandelic acid intermediate is less than 2.0%, and the dropping speed of the alkali solution is controlled to make the pH of the solution 11-13. The raw material solution was dropped in about 6 hours, then the tempe...

Embodiment 3

[0026] Catalyst preparation: Weigh 7.5g (0.03mol) of reagent copper sulfate and 7.2g (0.03mol) of reagent cobalt sulfate, and dissolve them in 100mL deionized water to prepare a metal salt solution. The rare earth Y-type molecular sieve (Re 2 o 3 ≥17%; SiO 2 / Al 2 o 3 ≥5;Na 2 O ≤ 2%; loss on ignition ≥ 3%) 100g was added to the above metal salt solution and soaked for 30 minutes, then 5% sodium hydroxide solution was added dropwise to pH 11, molecular sieves were separated by vacuum filtration, washed with a small amount of deionized water to remove sodium sulfate Salt, dry at 105°C, oxidize and roast in a high-temperature furnace at 550°C for 60 minutes, and set aside.

[0027]The catalyst is applied to the synthesis of vanillin: 74.1g (0.4mol) 40% glyoxylic acid, 54.0g (0.48mol) guaiacol and 100mL30% Liquid caustic soda. Add 500 mL of deionized water, 106.6 g (0.8 mol) of 30% liquid caustic soda into the four-necked reaction flask, add 5.0 g of catalyst, stir and blow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com