Edge finishing method of capacitive touch screen

A technology of capacitive touch screen and edge processing, applied in the direction of electrical digital data processing, input/output process of data processing, instruments, etc., can solve the problems of increasing processing steps and processing costs, not being able to process external panels, and reducing production yield , to achieve the effect of saving processing steps and improving processing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0034] Embodiment 1 (for capacitive touch screens of all structures)

[0035] The edge processing method of this capacitive touch screen is characterized in that comprising the following steps:

[0036] Step 1, such as Figure 4 As shown, organic resin is used to coat the inside of the outer panel 1 to form the inner protective layer 2; the thermal melting temperature of the organic resin forming the inner protective layer 2 is between 150-200°C, and the refractive index of the inner protective layer 2 is between that of the electrode material Between air and air, the thickness of the inner protective layer 2 is 1-5 μm.

[0037] Step two, such as Figure 4 As shown, the outer protective layer 3 is formed by coating the outer surface of the outer panel 1 with an organic resin; and the thickness of the outer protective layer 3 is set to 20-100 nm.

[0038] Step three, such as Figure 5 As shown, the abrasive tool 4 with a tapered longitudinal section is used to grind away the ...

Embodiment approach 2

[0041] Embodiment 2 (for capacitive touch screens of all structures)

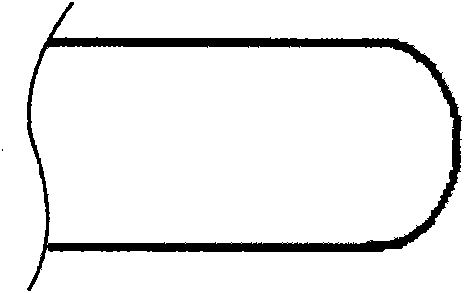

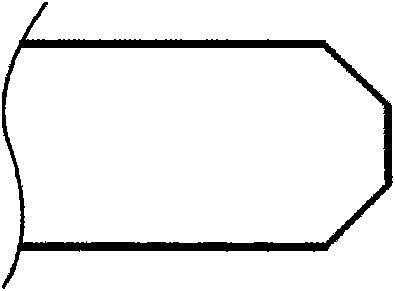

[0042] Such as Figure 8 As shown, in the case that the other steps are the same as those in the first embodiment, in step 3, while the inner protective layer 2 and the outer protective layer 3 in the inner and outer edge regions of the outer panel 1 are worn away, the part of the exposed area 5 is further worn away Outer panel 1 plate quality 7, forms pre-etched shape 9, further etches as Figure 9 The sleek shape shown in 8. The pre-etched shape 9 can be as Figure 10 The protruding inclined shape 10 can also be as Figure 11 The upper and lower asymmetric shapes 12 are shown.

Embodiment approach 3

[0043] Embodiment 3 (for capacitive touch screens with the first and second structures)

[0044] This embodiment is mainly aimed at capacitive touch screens with the first and second structures. In order to save costs, when other steps are the same as those in Embodiment 1 or Embodiment 2, the difference is that in Step 1 and Step 2, the internal protection Both the first layer and the outer protective layer use ordinary organic resin, and there is no need to limit the thickness of the inner protective layer and the outer protective layer, and after step 4 is completed, the inner protective layer and the outer protective layer are peeled off by a peeling process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com