Method for enriching and culturing anaerobic ammonia oxidizing bacteria by using membrane bioreactor

A membrane bioreactor, anaerobic ammonium oxidation technology, applied in the direction of bacteria, aerobic and anaerobic process, can solve the problems of low enrichment efficiency and long enrichment time of anammox bacteria, and achieve enrichment The effect of improving efficiency, shortening enrichment time, and rapid enrichment culture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

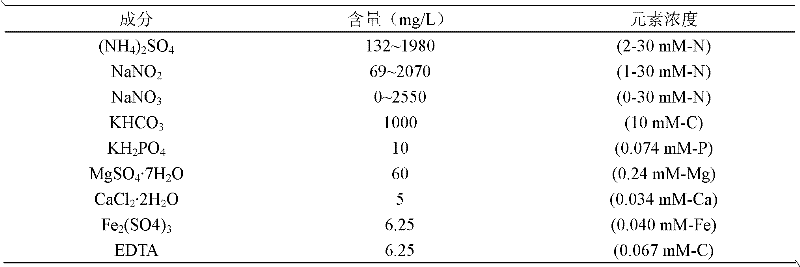

[0014] Specific embodiment one: the present embodiment utilizes the method for enriching and cultivating anammox bacteria in a membrane bioreactor, and is characterized in that the method for cultivating anammox bacteria using a membrane bioreactor as an enrichment reactor is realized in the following steps: 1. Add the simulated sewage medium into the water tank of the membrane bioreactor, and take the sludge from the anoxic biochemical pool of the A / O process of the urban sewage plant. Store anaerobically at room temperature for 3 to 5 days, and then inoculate the sludge in the anaerobic tank of the membrane bioreactor. The inoculation conditions of the sludge are 9920-9940 mg / L of total suspended solids and 4300-9940 mg / L of volatile suspended solids. 4340mg / L, the inoculum volume is 2-4L; 2. After inoculation, carry out enrichment culture in the membrane bioreactor. 7.5~8.5, the dissolved oxygen in the water is 0.06~0.09mg / L, the pH value in the anaerobic tank is 7.0~8.0, t...

specific Embodiment approach 2

[0015] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the temperature of the anoxic biochemical pool is 17-19 ° C when the sludge is taken in step 1, and the sludge is anaerobically stored at room temperature for 4 days, and the inoculum size is 3 L . Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0016] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that mud discharge in step two refers to discharging 50 mL of mud-water mixture every day during enrichment culture for 1 to 20 days; During enrichment culture for 1 to 20 days, stop the operation of the membrane bioreactor for 30 minutes every day, and settle the sludge in the membrane bioreactor for 30 minutes, then remove 75% of the supernatant liquid in the membrane bioreactor by siphon method, Supplement the simulated sewage culture medium with the same volume as the excluded liquid to the membrane bioreactor. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com