High-reliability intelligent-card encapsulating glue and preparation method thereof

A technology of card encapsulation and reliability, applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as difficult to meet the requirements of high reliability, achieve superior water resistance and resistance to cold and heat cycles, shrinkage Low rate, good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

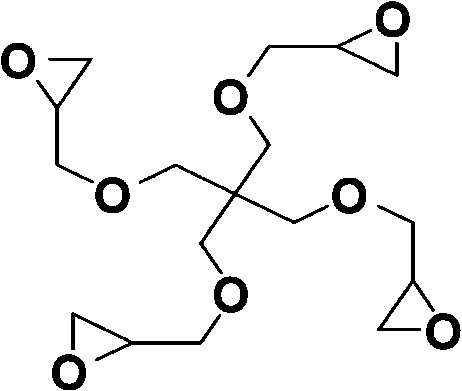

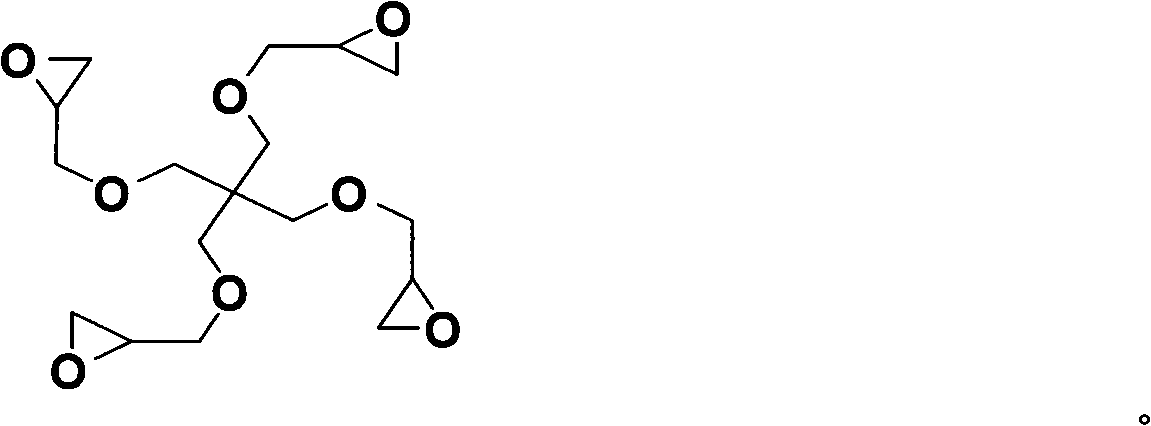

Image

Examples

Embodiment 1

[0025] Accurately weigh the following raw materials, 3,4-epoxycyclohexylmethyl-3,4-epoxycyclohexyl carboxylate 50g, functional resin 5g, 1,4-butanediol 2.5g, β-( 3,4-epoxycyclohexyl) ethyltrimethoxysilane 5g drops in reactor, and rotating speed 800 rev / mins, mixes 15 minutes at room temperature, then takes by weighing photoinitiator to be the IHT of Beijing Yingli Science and Technology Development Co., Ltd. - Put 0.5g of PT445 into the reaction kettle under the condition of avoiding light, rotate at 800 rpm, mix at room temperature for 15 minutes to make it a homogeneous solution, then weigh 37g of silicon micropowder, add it into the reaction kettle in three equal batches, The temperature is 20°C, the vacuum degree is -0.07MPa, the rotation speed is 800 rpm, and the mixture is stirred for 2 hours to obtain the product.

Embodiment 2

[0027] Accurately weigh the following raw materials, bis(7-oxabicyclo[4.1.0]3-heptylmethyl)adipate 30g, functional resin 10g, 1,4-butanediol 2g, γ-glycidol Put 5g of oxypropyltrimethoxysilane into the reaction kettle at a speed of 1000 rpm, mix at room temperature for 20 minutes, then weigh the photoinitiator as IHT-PT432 1g from Beijing Yingli Science and Technology Development Co., Ltd. under dark conditions Put it into the reaction kettle at a speed of 1000 rpm, mix at room temperature for 20 minutes to make it into a homogeneous solution, then weigh 52g of silicon micropowder, add it to the reaction kettle in three batches, at a temperature of 20°C and a vacuum of -0.05 MPa, rotating speed 1000 rpm, stirring and mixing for 2 hours to obtain the product.

Embodiment 3

[0029] Accurately weigh the following raw materials, bis(7-oxabicyclo[4.1.0]3-heptylmethyl)adipate 15g, bisphenol A epoxy resin (E51) 10g, functional resin 20g, 1 , 5g of 4-butanediol and 9g of γ-mercaptopropyltrimethoxysilane were put into the reactor at a speed of 1000 rpm, mixed at room temperature for 25 minutes, and then the photoinitiator was weighed as Beijing Yingli Technology Development Co., Ltd. Put 1g of IHT-PT4361g into the reaction kettle under the condition of avoiding light, rotate at 1000 rpm, mix at room temperature for 20 minutes to make it a homogeneous solution, then weigh 30g of silicon micropowder and 10g of quartz powder, and add them to the reaction in three equal batches In the kettle, at a temperature of 20°C, a vacuum degree of -0.05MPa, and a rotation speed of 1000 rpm, stir and mix for 2 hours to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com