Method for manufacturing high-strength carbon/carbon hot-press die

A technology of hot-pressing molds and manufacturing methods, which is applied in the field of hot-pressing molds, can solve problems such as low axial mechanical properties, lack of densification process, and poor integrity, and achieve the goals of increasing furnace loading, reducing thickness, and improving production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Step 1, the carbon fiber of 3K is impregnated with the speed of 0.5m / s by filling the glue tank of epoxy resin glue; The epoxy resin glue is epoxy resin and epoxy resin reactive diluent 660 (butyl butyl glycidyl ether) mixed resin glue, the epoxy resin reactive diluent diluent 660 (butyl glycidyl ether) in the epoxy resin glue is 10% by mass, and the balance is epoxy resin;

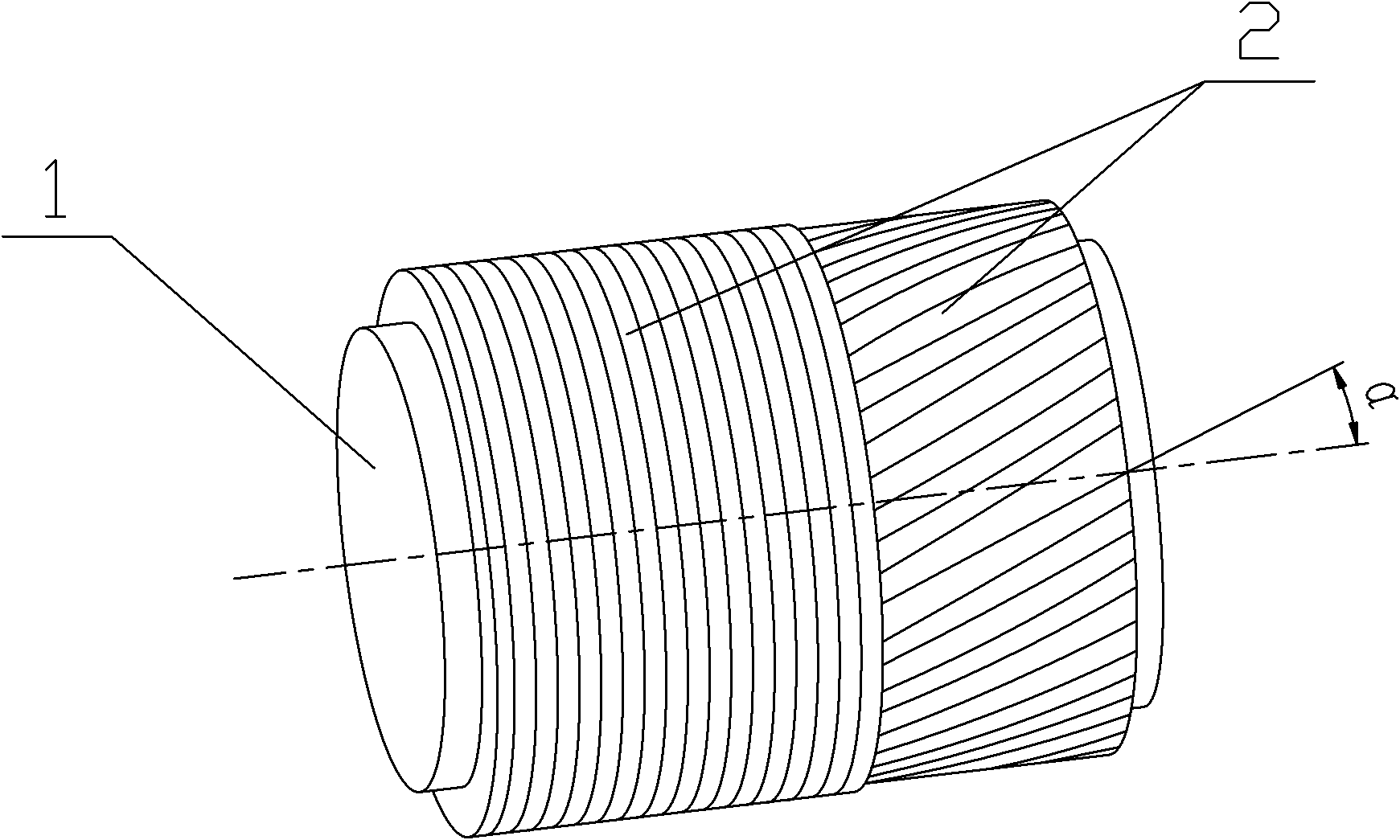

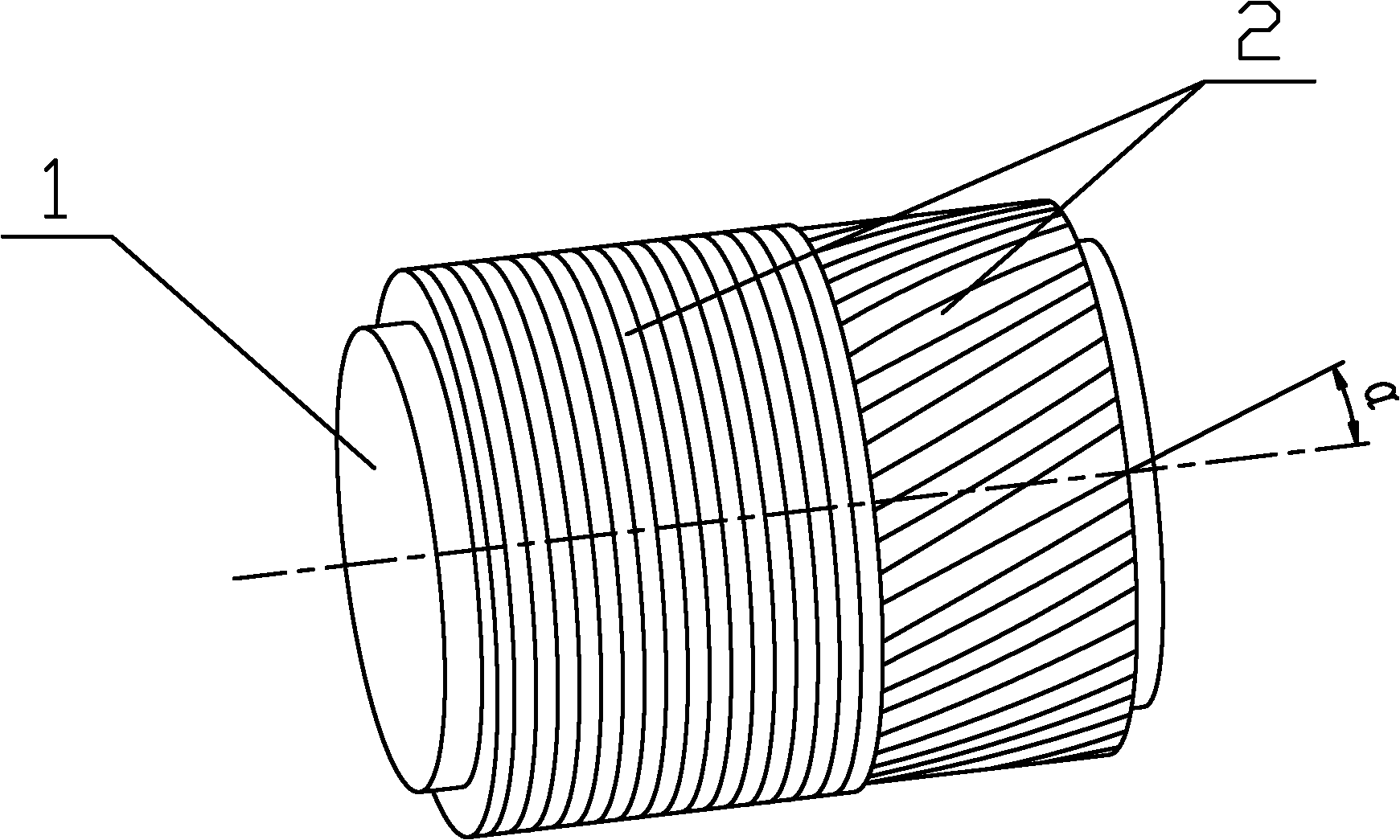

[0027] Step 2. Continuously wrap the impregnated carbon fiber in the graphite mandrel 1 in a hoop direction, wrap 3 layers in the hoop and then wrap 3 layers in the longitudinal direction, and repeat the winding until the desired diameter is reached. The direction of the longitudinal winding is The included angle with the graphite mandrel 1 axis is 10°;

[0028] Step 3. Put the preform in a resistance carbonization furnace, cure at 60°C for 60 hours, and then raise the temperature to 900°C at a heating rate of 15°C / h for carbonization;

[0029] Step 4, impregnating the carbonized preform in phenol...

Embodiment 2

[0033] Step 1, the carbon fiber of 12K is impregnated with the speed of 0.5m / s by filling the glue tank of epoxy resin glue; The epoxy resin glue is epoxy resin and epoxy resin reactive diluent 660 (butyl butyl glycidyl ether) mixed resin glue, the epoxy resin reactive diluent diluent 660 (butyl glycidyl ether) in the epoxy resin glue by mass percent is 20%, and the balance is epoxy resin;

[0034] Step 2. Continuously wrap the impregnated carbon fiber in the graphite mandrel 1 in a hoop direction, wrap 5 layers in the hoop, then wrap 1 layer longitudinally, and repeat the winding until the desired diameter is reached. The direction of the longitudinal winding The included angle with the axis of the graphite mandrel 1 is 20°;

[0035] Step 3: Put the preform in a resistance carbonization furnace, cure at 80°C for 60 hours, and then raise the temperature to 900°C at a heating rate of 20°C / h for carbonization;

[0036] Step 4, immerse the carbonized preform in pitch for 8 hours...

Embodiment 3

[0040] Step 1, the carbon fiber of 8K is impregnated with the speed of 0.5m / s by filling in the glue tank of epoxy resin glue solution; Described epoxy resin glue solution is epoxy resin and epoxy resin active thinner 660 (but butyl glycidyl ether) mixed resin glue, the mass percent of epoxy resin reactive diluent diluent 660 (butyl glycidyl ether) in the epoxy resin glue is 15%, and the balance is epoxy resin;

[0041] Step 2: Continuously wrap the impregnated carbon fiber in the graphite mandrel 1 in a hoop direction, wrap 4 layers in the hoop, then wrap 2 layers in the longitudinal direction, and repeat the winding until the desired diameter is reached. The direction of the longitudinal winding is The included angle with the axis of the graphite mandrel 1 is 30°;

[0042] Step 3: Put the preform in a resistance carbonization furnace, cure at 70°C for 60 hours, and then raise the temperature to 900°C at a heating rate of 18°C / h for carbonization;

[0043] Step 4, immerse th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com