Method for recovering celestite from waste residue in strontium carbonate production by celestite back salt method

A technology of lapis lazuli and strontium carbonate, which is applied in the removal of solid waste, calcium/strontium/barium sulfate, etc., can solve the problems of waste of resources, low utilization rate of lapis lazuli resources, environmental pollution, etc. Low cost and the effect of eliminating environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

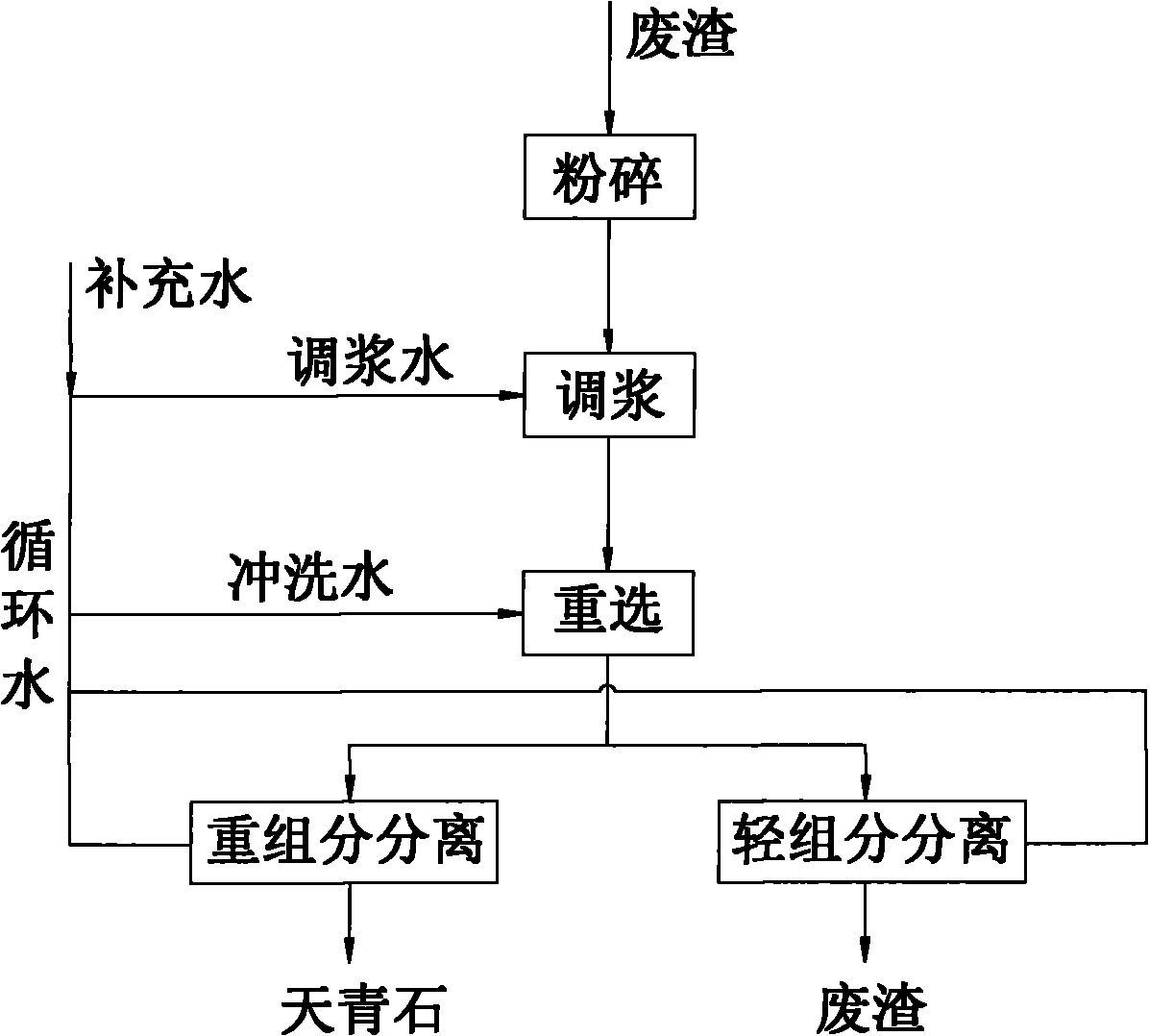

[0029] Example 1. refer to figure 1 , the method of recovering celestite from the waste slag of strontium carbonate produced by celestite black ash method, the waste slag containing 25% strontium sulfate is crushed to obtain waste slag powder; the particle size of waste slag crushing is required to be 120 mesh; 35% slurry; using a shaking table at a stroke rate of 300 times / min and a stroke of 13mm; when the flushing volume is 5 times the amount of slurry; select light components and heavy components in the slurry; dehydrate the heavy components , and dried to obtain lapis lazuli powder, the experimental results showed that the yield was 89.8%, and the grade was 85.0%.

Embodiment 2

[0030] Example 2. refer to figure 1 , the method of recovering celestite from the waste slag of strontium carbonate produced by celestite black ash method, the waste slag containing 25% strontium sulfate is crushed to obtain waste slag powder; the particle size of waste slag crushing is required to be 120 mesh; 40% slurry; use a shaker at 300 strokes per minute, stroke 13mm; when the amount of flushing water is 5 times the amount of slurry; select light components and heavy components in the slurry; dehydrate the heavy components , and dried to obtain lapis lazuli powder, the experimental results showed that the yield was 90.8%, and the grade was 84.6.0%.

Embodiment 3

[0031] Example 3. refer to figure 1 , the method of recovering celestite from the waste slag of strontium carbonate produced by celestite black ash method, the waste slag containing 25% strontium sulfate is crushed to obtain waste slag powder; the particle size of waste slag crushing is required to be 120 mesh; 38% slurry; using a shaker at a stroke rate of 300 times per minute and a stroke of 13 mm; when the flushing volume is 5 times the amount of slurry; select light components and heavy components in the slurry; dehydrate the heavy components , and dried to obtain lapis lazuli powder, the experimental results showed that the yield was 90.4%, and the grade was 84.4.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com