Flexible structure for vacuum-pumping system of vibratory forming machine

A vibration molding machine and vacuuming system technology, applied in ceramic molding machines, mechanical equipment, pipe components, etc., can solve the problems of high price and inability to obtain, and achieve technical obstacles, simple structure and low manufacturing cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

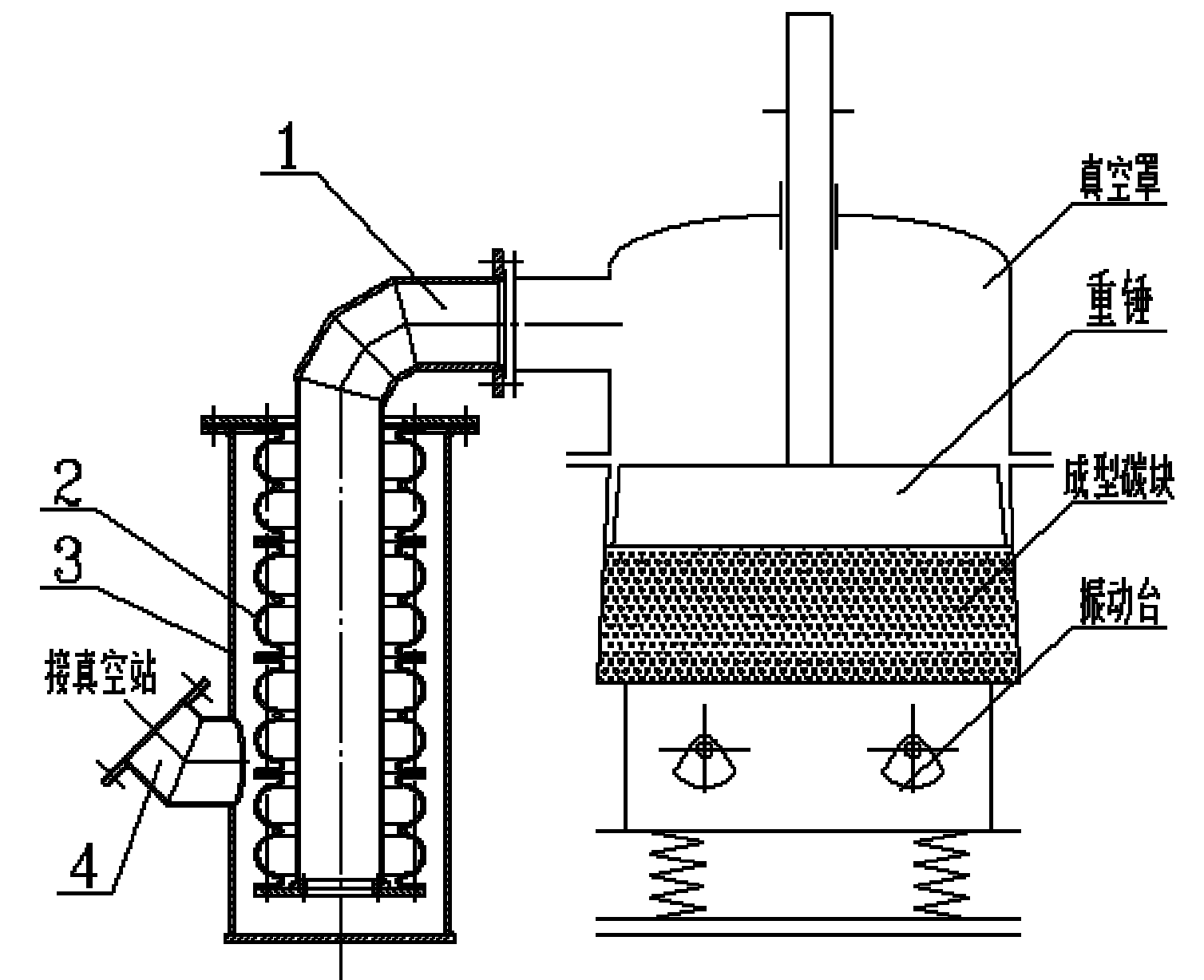

[0009] The embodiment of the present invention: one end of the inner tube 1 is connected to the vacuum cover on the vibration table, and the other end passes through the inner cavity of the airbag group 2 and is connected to the bottom of the airbag group 2. The whole airbag group 2 is installed in the housing 3, and the airbag The top of the group 2 is connected to the inner side of the top of the shell 3, and the shell 3 is connected to a vacuum station with a tube 4, and the shell is fixed on the frame or foundation of the vibration forming machine.

[0010] The working principle of the invention: when the carbon block is formed, the vacuum cover is buckled on the mold sleeve of the vibration table and vibrates together with the vibration table, the inner tube is put down together with the vacuum cover, and the airbag group is also stretched (see attached figure 1 ), and then the vacuum station starts to vacuum, the gas in the vacuum cover enters the outer shell 3 through the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com