Method for generating cold plasma by discharge under high pressure and dielectric barrier discharge device

A technology of cold plasma and high pressure, which is applied in the field of plasma, can solve the problems of rising gas temperature, prolonging the discharge pulse time, and waste of electric energy, so as to reduce the discharge breakdown voltage and increase the discharge channel density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings, without any limitation to the present invention.

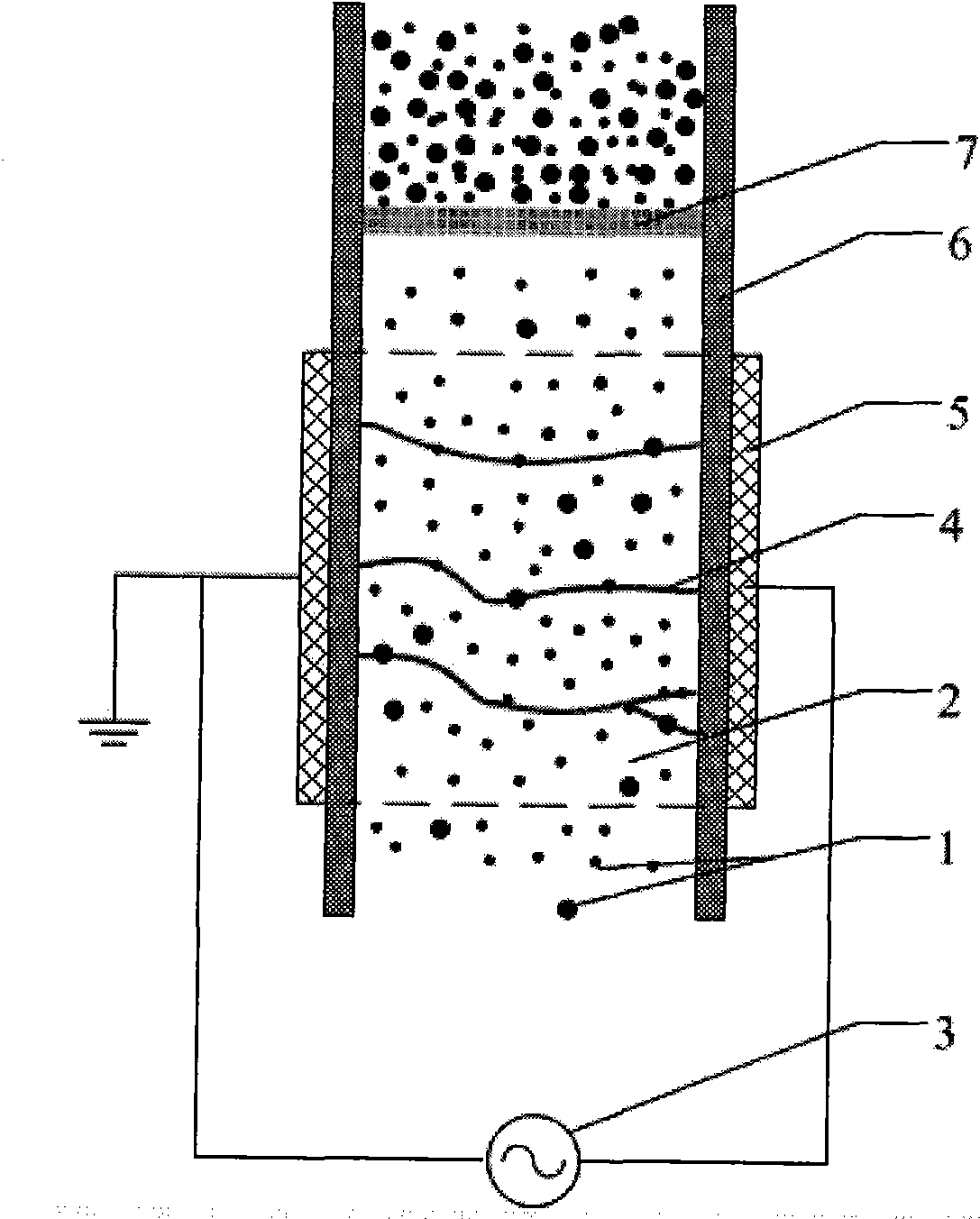

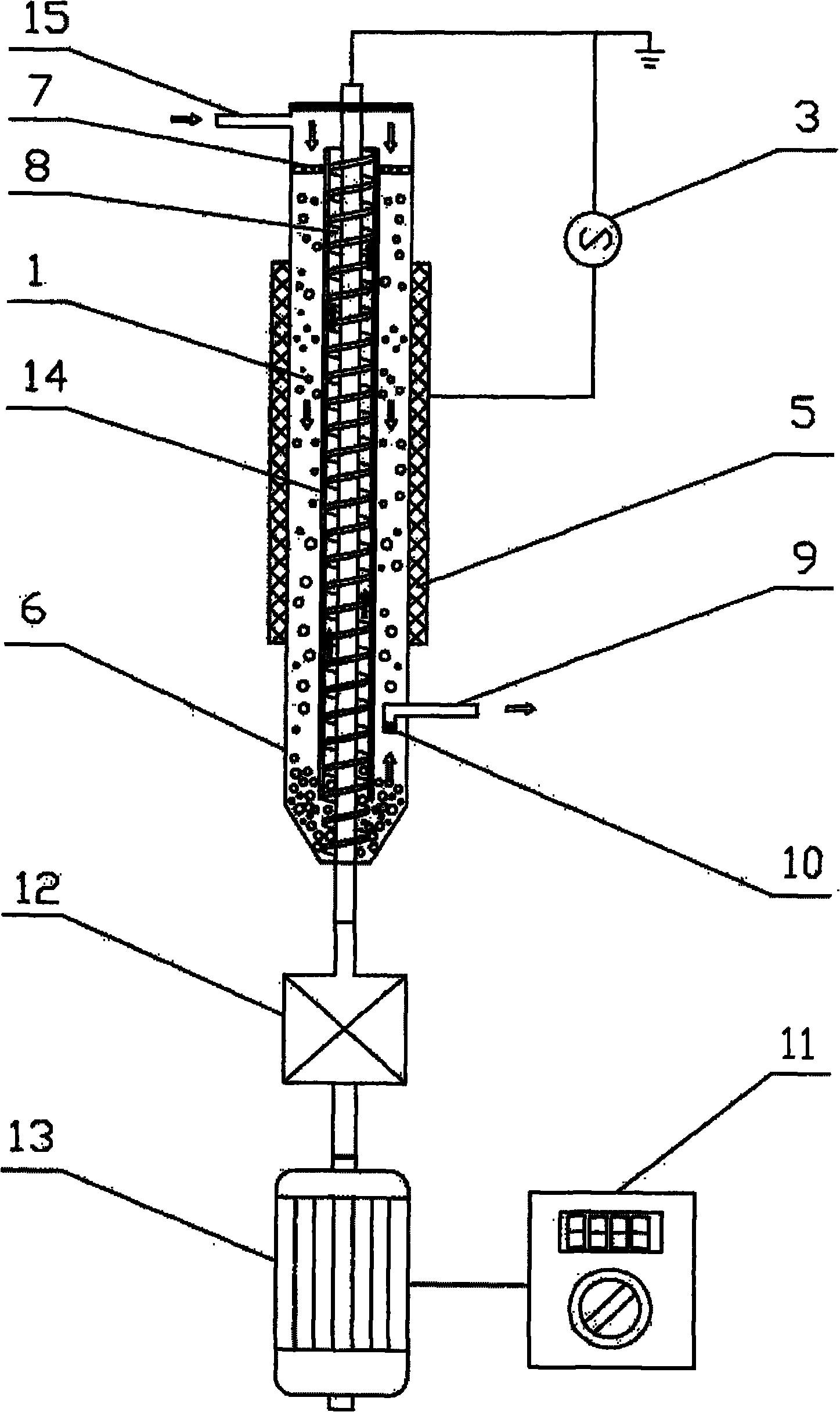

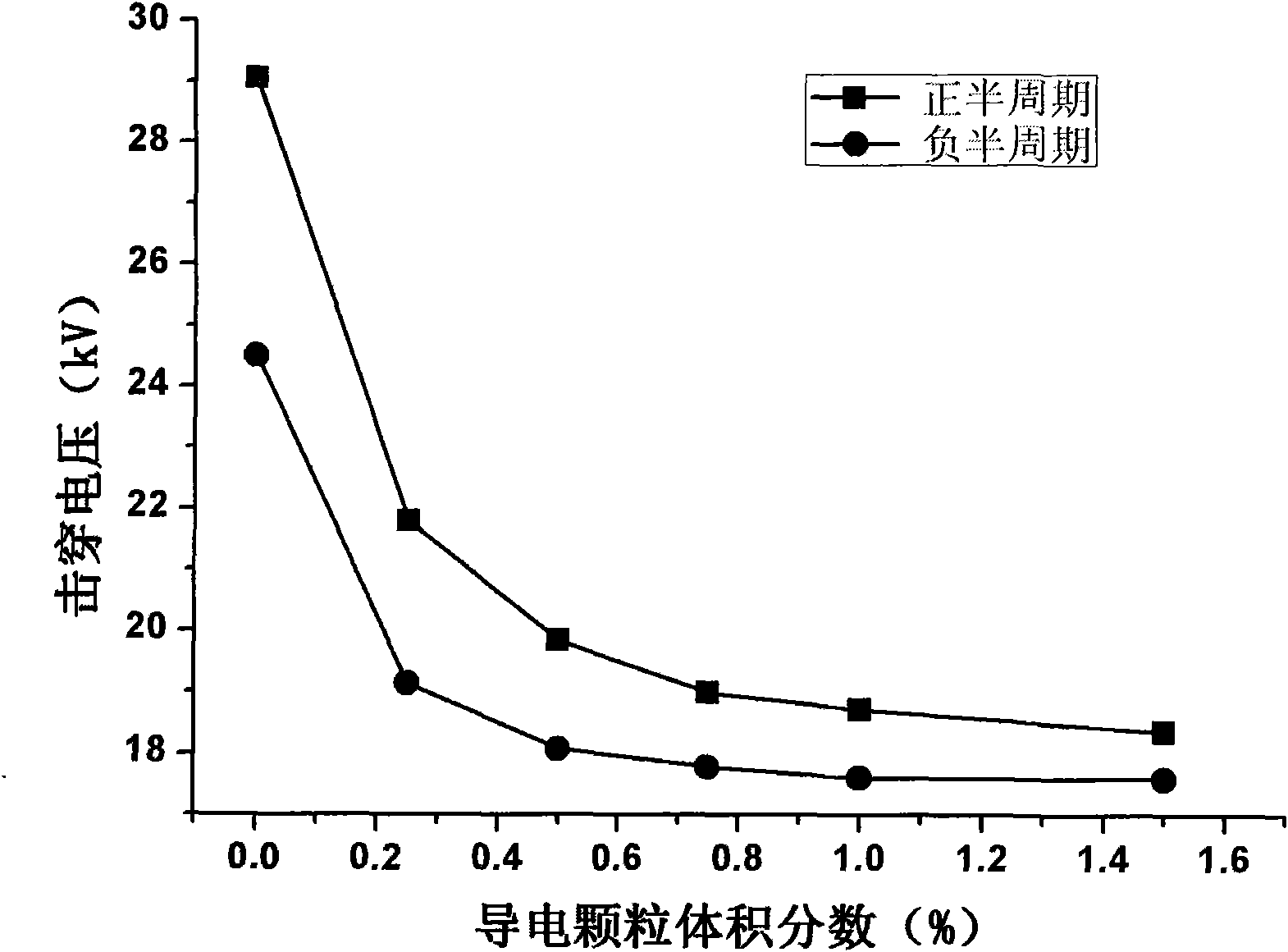

[0025] Description of drawings: figure 1 It is a schematic diagram of a dielectric barrier discharge principle device of the present invention; figure 2 It is a schematic diagram of an embodiment of the dielectric barrier discharge device of the present invention; image 3 yes figure 2 Implement the experiment result of example conductive particle (carbon powder) concentration to reduce discharge voltage effect; Figure 4 yes figure 2 Implementation example The experimental results of the effect of the concentration of conductive particles on increasing the discharge density.

[0026] figure 1 It is a schematic diagram of a dielectric barrier discharge principle device applying the above principle method. Among them, a pair of discharge electrodes 5 separated and placed in parallel, an insulating dielectric barr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com