Mesoporous silicon oxide particle/degradable polymer nano composite fiber, preparation method and application thereof

A technology of nanocomposite fibers and mesoporous silica, which is applied in the direction of non-active components of polymer compounds, chemical post-treatment of synthetic polymer artificial filaments, fiber treatment, etc., can solve problems such as composite materials that are rarely reported, and achieve improved mechanical properties. Effects of strength and biodegradability, high activity loading, high activity controlled release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

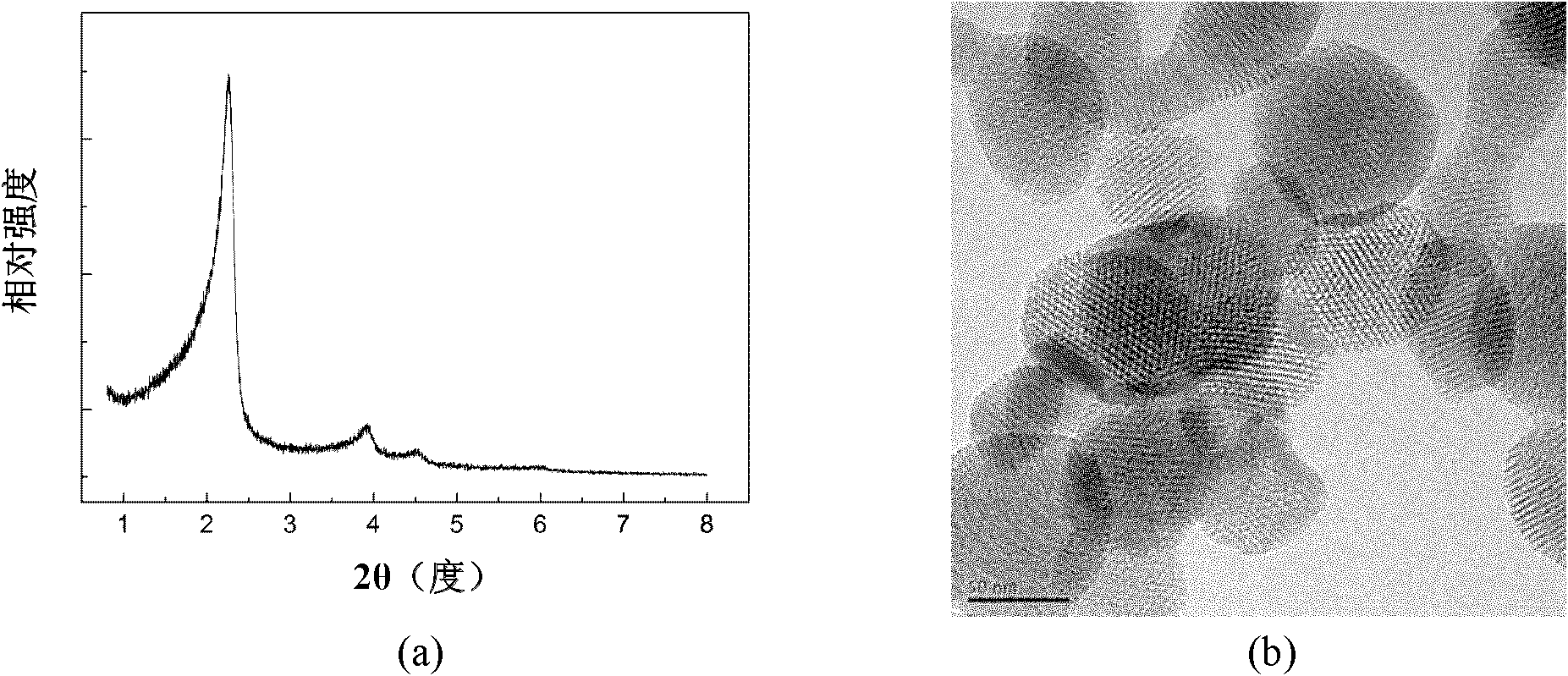

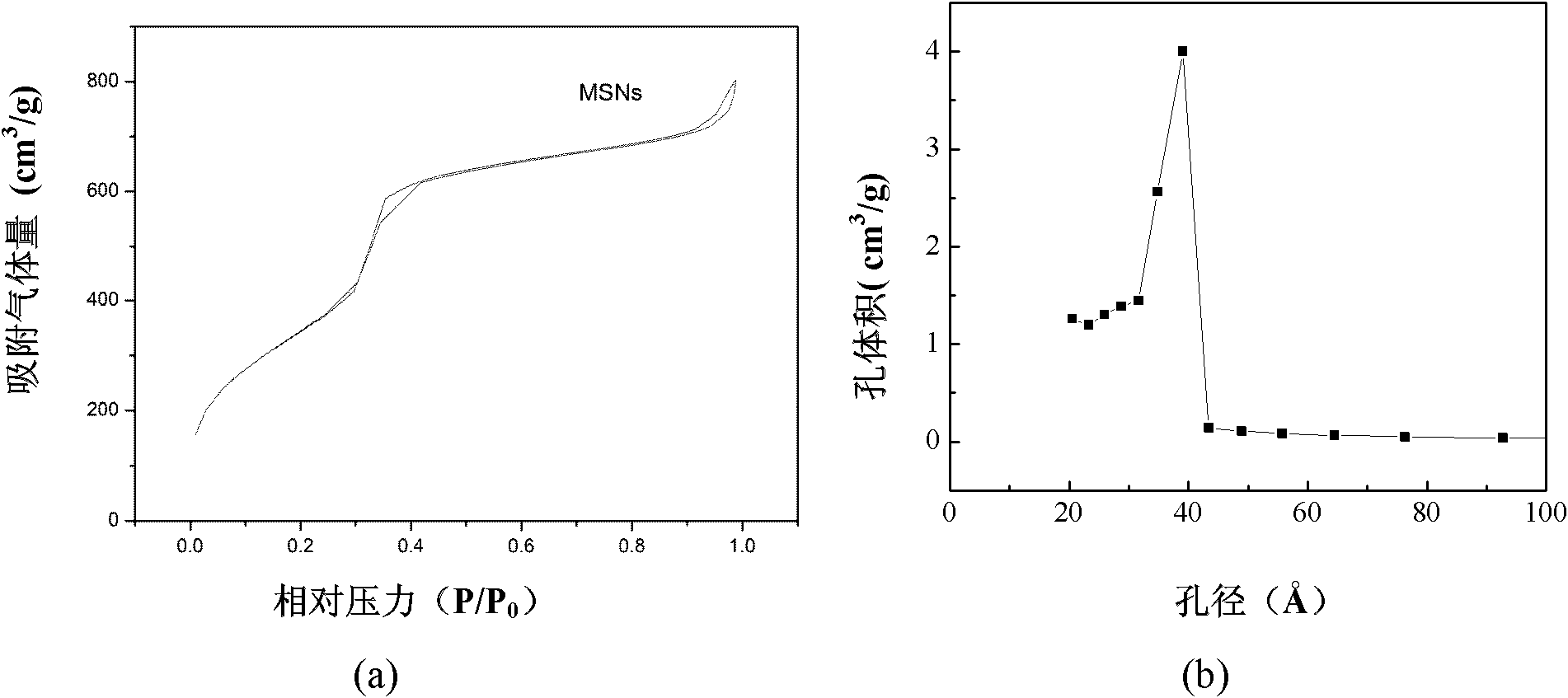

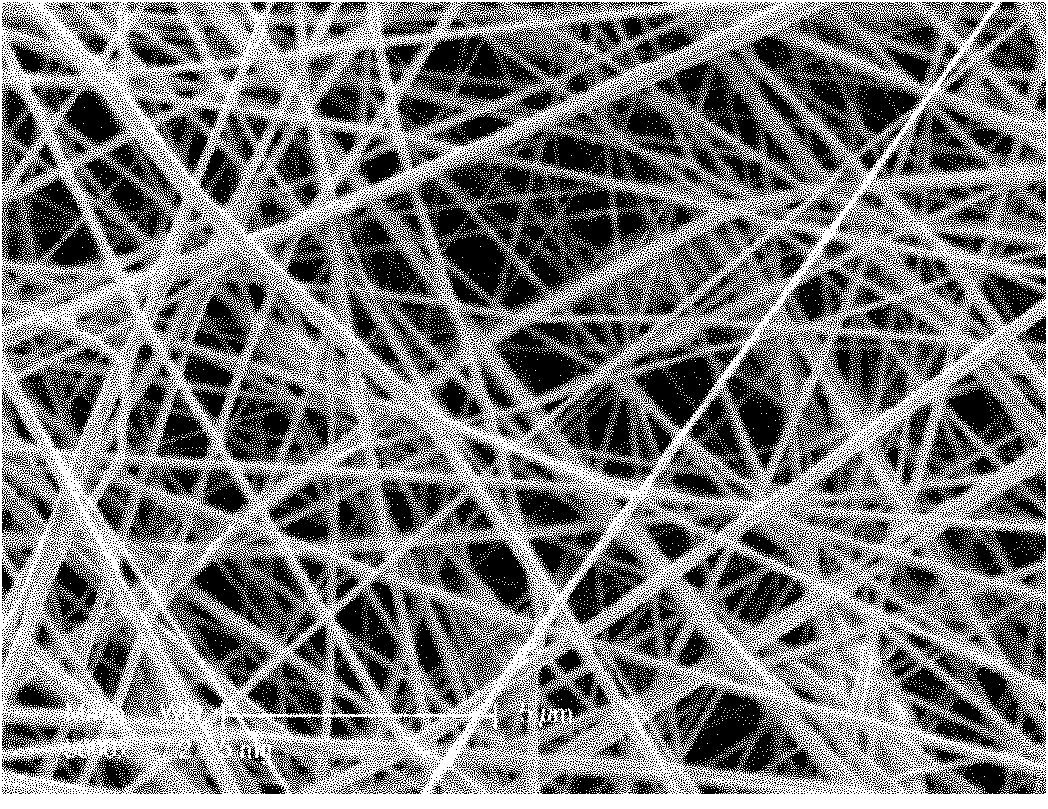

[0048] Example 1 Preparation of Mesoporous Silica Nanoparticles MSN-1

[0049] Weigh 1.116g of cetyl dimethyl sodium bromide, add 880 mL of deionized water, raise the temperature to 50°C, and keep the temperature for 2 hours until the cetyl dimethyl sodium bromide is completely dissolved. Then 52.8mL of 27% concentrated ammonia water was added, and after 10min, 5.6mL of ethyl orthosilicate was slowly added dropwise. Stir at constant temperature for 2h to stop heating, the reaction is terminated, and stand for aging for 2h. Then, pour off the supernatant, centrifuge and wash with ultrapure water and absolute ethanol twice respectively. Finally, it was extracted and refluxed in methanol / hydrochloric acid system for 24 hours, and then washed twice with ethanol. Finally dried, ground and collected. The obtained mesoporous material (referred to as MSN-1) was measured by X-Ray diffraction analysis, transmission electron microscope, nitrogen isothermal adsorption-desorption, etc. ...

Embodiment 2

[0050] Example 2 Preparation of Mesoporous Silica Nanoparticles MSN-2

[0051] Weighing 12g (EO 20 PO 70 EO 20 ; Average molecular weight is 5800, Aldrich company) add in the 37% concentrated hydrochloric acid of 312mL deionized water and 60mL. After the surfactant was completely dissolved, 27.5 mL of ethyl orthosilicate was added. After stirring at room temperature for 24 hours, it was then poured into a special airtight tetrafluoroethylene container and hydrothermally crystallized at 100°C for 24 hours. The obtained suspension was centrifuged, washed twice with water and ethanol, calcined at 600°C for 6 hours, and then ground. The obtained mesoporous material (referred to as MSN-2) has a pore size of 9.8 nm. BET calculation results show that the specific surface area of the material is 520m 2 / g.

Embodiment 3

[0052] Example 3 Preparation of Mesoporous Silica Nanoparticles MSN-3

[0053] Weigh 0.98g of hexadecyldimethyl sodium bromide, add it into 380mL of deionized water, raise the temperature to 30°C, and keep the temperature for 2 hours until the hexadecyldimethyl sodium bromide is completely dissolved. Then 52.8mL of 27% concentrated ammonia water was added, and after 10min, 5.6mL of ethyl orthosilicate was slowly added dropwise. Stir at constant temperature for 2h to stop heating, the reaction is terminated, and stand for aging for 2h. Then, pour off the supernatant, centrifuge and wash with ultrapure water and absolute ethanol twice respectively. Finally, it was extracted and refluxed in methanol / hydrochloric acid system for 24 hours, and then washed twice with ethanol. Finally dried, ground and collected. The obtained mesoporous material (referred to as MSN-3) has a pore size of 3.6 nm. The specific surface area of the material calculated by BET is 200m 2 / g.

[0054]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com