Method for producing microbial ecological agent by using kitchen garbage

A technology for micro-ecological preparations and kitchen waste, applied in the biological field, can solve the problems of ineffective utilization of cellulose, low yield of ethanol or biogas, homology of animal feed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

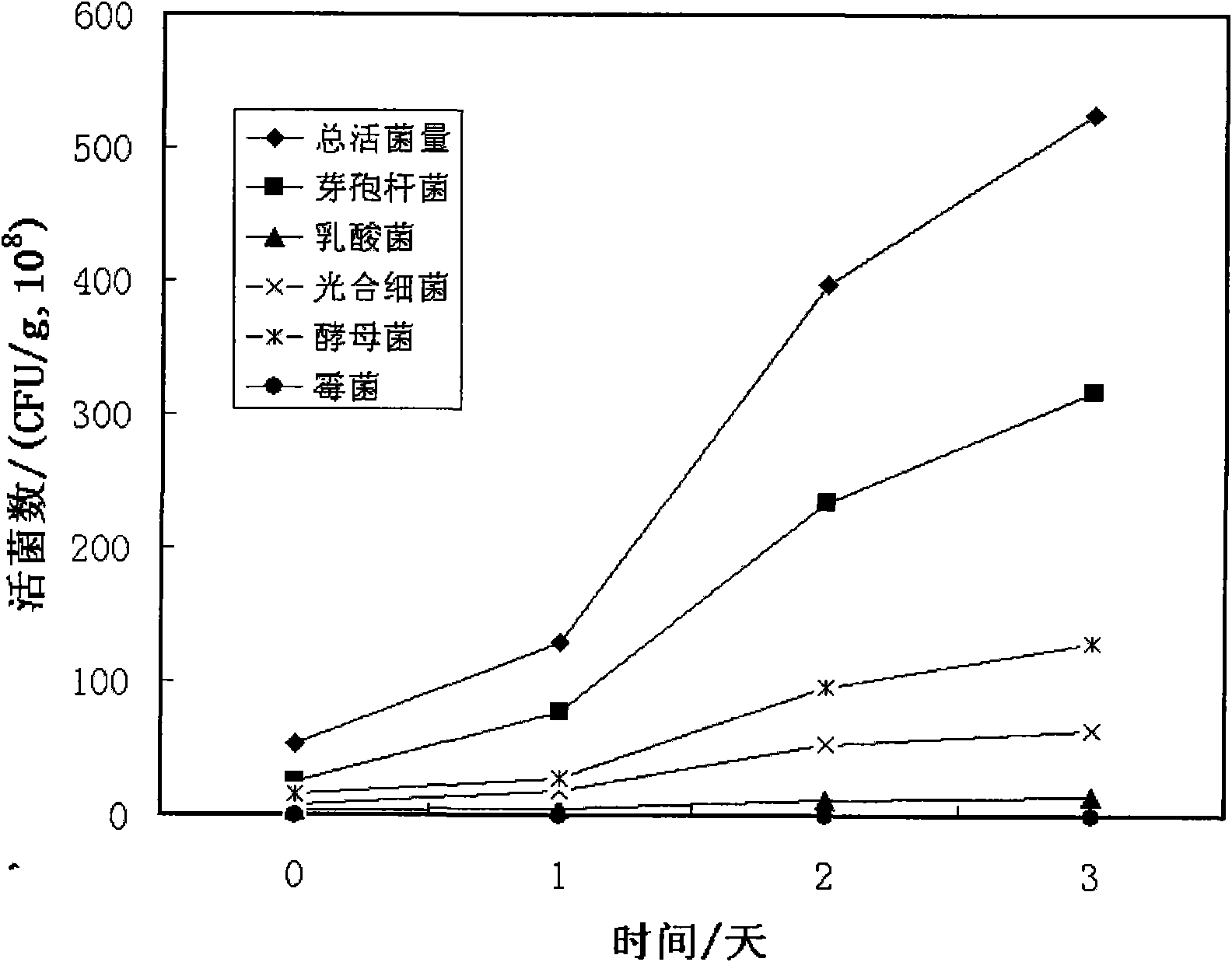

Embodiment 1

[0019] First, 500g of food waste including rice, noodles, meat, eggs, fruits and vegetables collected from the canteen was crushed by a crusher, and then the crushed food waste was put into a glass container and sterilized at 100°C for 20 minutes. , when the temperature drops to 30°C, add 50g of crushed rice husks as a carrier, and at the same time add 50ml of 9 kinds of probiotics including 3 kinds of Bacillus (Bacillus natto, Bacillus coagulans, Bacillus subtilis), 1 photosynthetic A mixed probiotic agent composed of bacteria (Rhodoceus swamp), 2 kinds of yeast (Saccharomyces cerevisiae, Candida), 2 kinds of lactic acid bacteria (Lactic acid bacteria, Lactobacillus acidophilus) and 1 kind of mold (Rhizobia), After fully stirring, put it into a closed stainless steel container for anaerobic fermentation culture. The culture conditions were temperature 25°C, stirring 3 times a day, and samples were taken every day to detect the viable bacteria content of different probiotics. ...

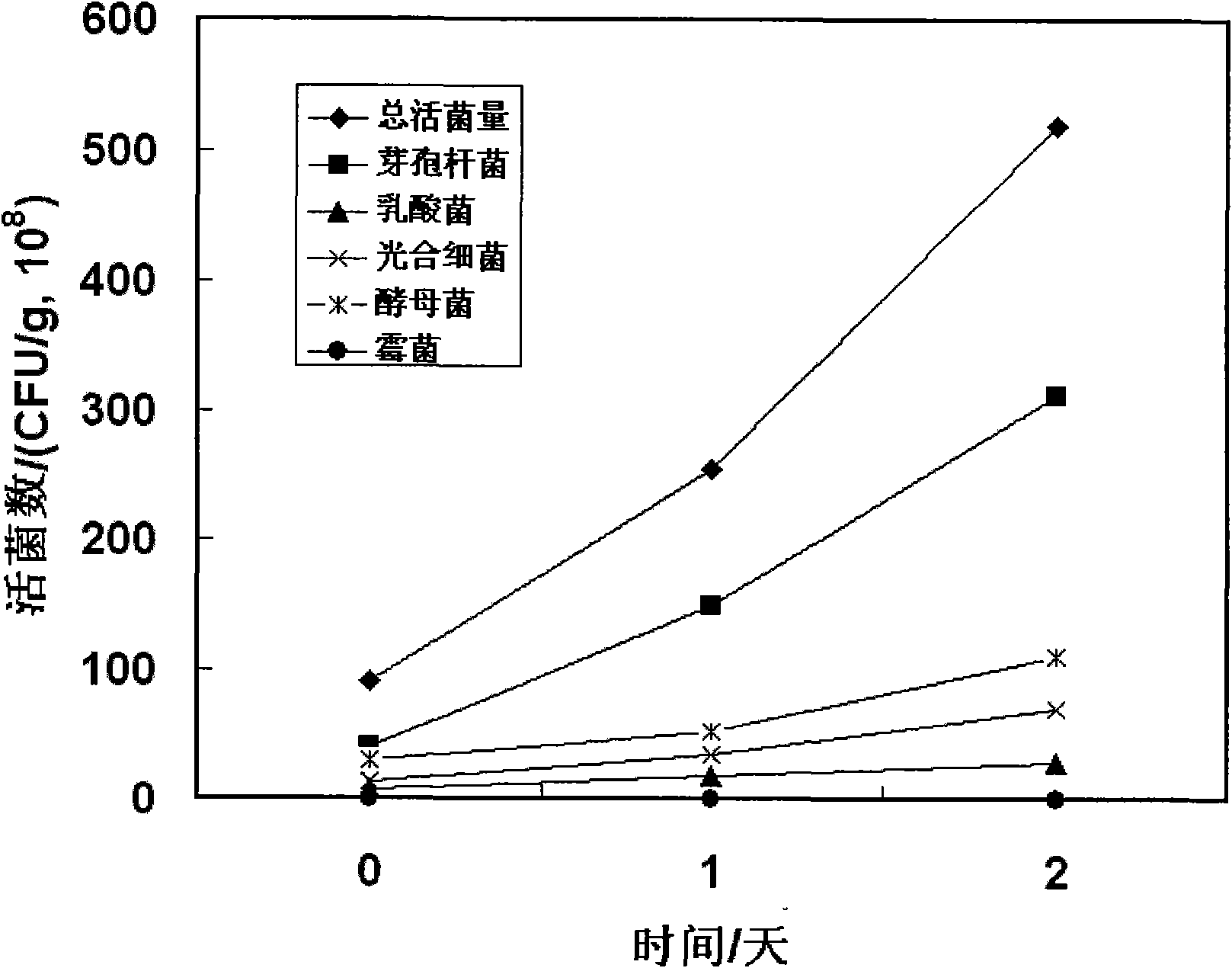

Embodiment 2

[0021] First, 500g of food waste including rice, noodles, meat, eggs, fruits and vegetables collected from the cafeteria was pulverized by a pulverizer, and then the pulverized food waste was put into a glass container and sterilized at 68°C for 30 minutes. , when the temperature drops to 40°C, add 150g of crushed wheat bran as a carrier, and at the same time add 100ml of 9 kinds of probiotics including 3 kinds of Bacillus (Bacillus natto, Bacillus coagulans, Bacillus subtilis), 1 photosynthetic A mixed probiotic agent composed of bacteria (Rhodoceus swamp), 2 kinds of yeast (Saccharomyces cerevisiae, Candida), 2 kinds of lactic acid bacteria (Lactic acid bacteria, Lactobacillus acidophilus) and 1 kind of mold (Rhizobia), After fully stirring, put it into a closed stainless steel container for anaerobic fermentation culture. The culture conditions were 35°C, stirring 3 times a day, and samples were taken every day to detect the viable bacterial content of different probiotics....

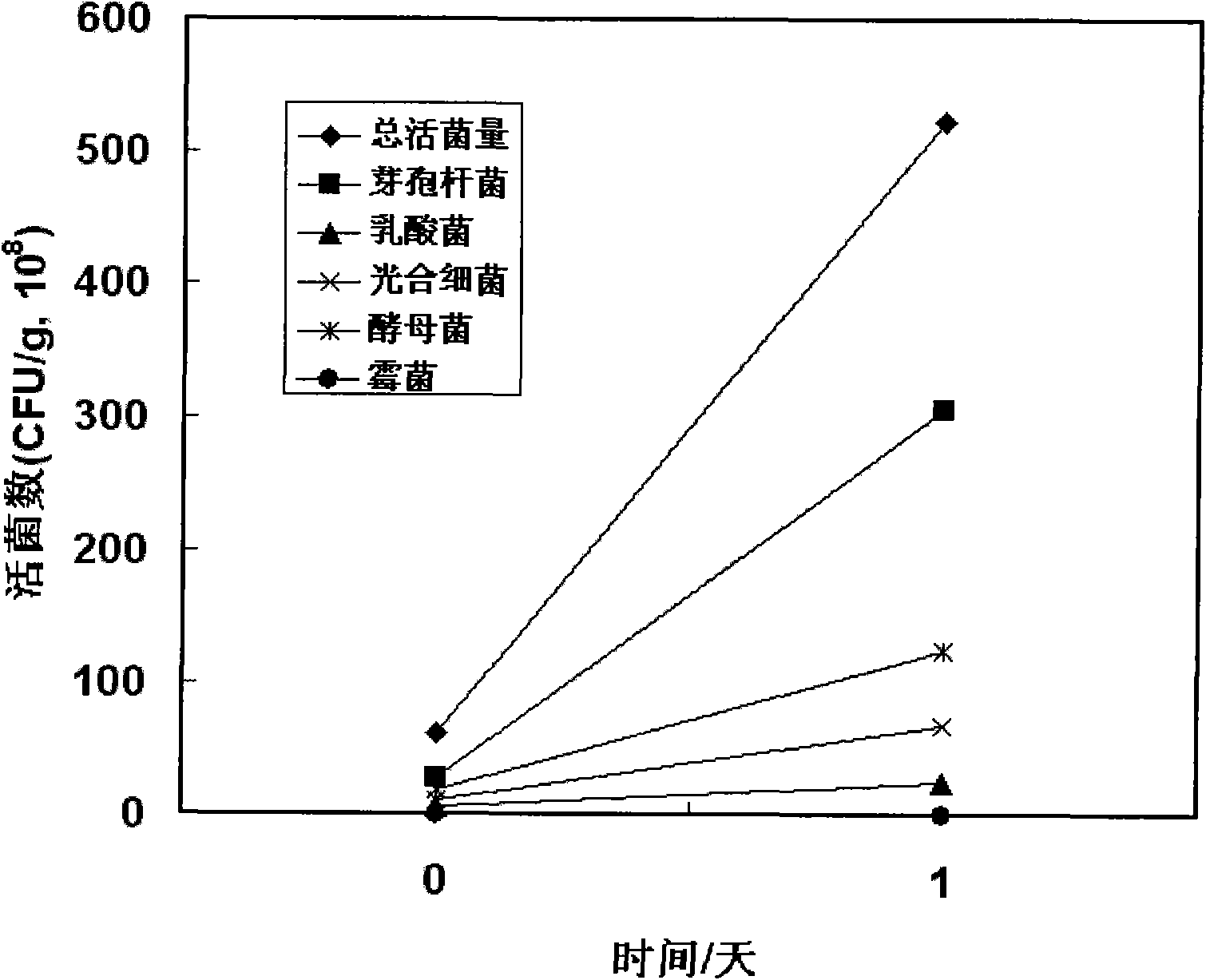

Embodiment 3

[0023] First, 500g of food waste including rice, noodles, meat, eggs, fruits and vegetables collected from the cafeteria was pulverized by a pulverizer, and then the pulverized food waste was put into a glass container and sterilized at 82°C for 20 minutes. , when the temperature is lowered to 40 ° C, add 1500 g of crushed starch, rice bran, rice husk, and wheat bran mixture as a carrier, and add 250 ml of 9 kinds of probiotics including 3 kinds of Bacillus (Bacillus natto, Bacillus coagulans) simultaneously. , Bacillus subtilis), 1 type of photosynthetic bacteria (Rhodoconas marsh), 2 types of yeast (Saccharomyces cerevisiae, Candida), 2 types of lactic acid bacteria (Lactic acid bacteria, Lactobacillus acidophilus) and 1 type of mold (Rhizobia ), the mixed probiotics are fully stirred and put into a closed glass container for anaerobic fermentation culture. The culture conditions were temperature 40°C, stirring 3 times a day, and samples were taken every day to detect the vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com