Process method for producing aromatic hydrocarbon by moving bed continuous reforming

A process method and moving bed technology, applied in the field of aromatic hydrocarbon production, can solve the problems of low catalyst activity, low reaction efficiency, slow catalyst renewal speed, etc., and achieve the goal of improving overall activity, improving economic benefits, and improving market adaptability and resilience. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

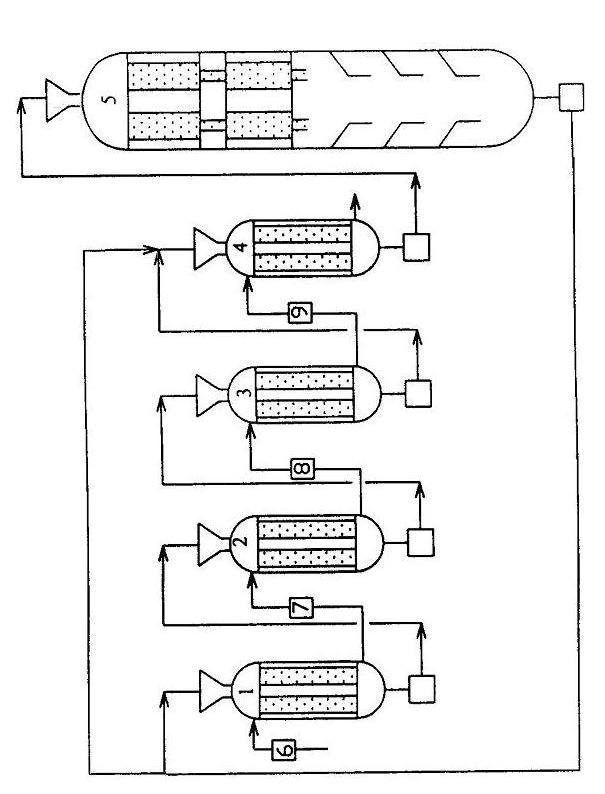

Image

Examples

Embodiment 1

[0027] In the embodiment, the catalysts used in the prehydrogenation of naphtha raw materials are as follows: Mo-Ni / alumina catalyst uses the FH-40A catalyst developed by Fushun Petrochemical Research Institute, Mo-Co / alumina catalyst uses Fushun Petrochemical Research Institute The developed FDS-4A catalyst and W-Mo-Ni-Co / alumina catalyst use the FH-40C catalyst developed by Fushun Petrochemical Research Institute. The main properties of the catalyst are listed in Table 1. FH-40A catalyst and FDS-4A catalyst are mixed in proportion to form the first catalyst bed (bed Ⅰ), FH-40C catalyst forms the second catalyst bed (bed Ⅱ), and the reaction materials pass through bed Ⅰ and bed in turn. II. There are mainly three types of naphtha raw materials used, and the specific properties are shown in Table 2. Raw material 1 is straight run naphtha of a certain domestic crude oil, raw material 2 is straight run naphtha of imported crude oil, and raw material 3 is a mixture of imported ...

Embodiment 1~3

[0033] Adopt the method of the present invention, raw material and hydrogen pass through bed I and bed II successively under hydrogenation condition, bed I is the mixed catalyst bed of Mo-Ni type catalyst and Mo-Co type catalyst, bed II is W- Mo-Ni-Co type catalyst.

[0034] Different catalyst ratios can be used to effectively process different types of raw materials, so that the oil produced by hydrogenation meets the requirements of catalytic reforming feed. The specific process conditions and reaction results are shown in Table 3.

[0035] Table 3 Main process conditions and properties of hydrogenated oil in Examples 1-3.

[0036] Example

[0037] Reaction pressure / MPa

Embodiment 4

[0039] According to the catalyst compounding scheme in Example 1, different raw materials can be processed at a higher space velocity, and qualified catalytic reforming raw materials can be obtained. The specific conditions and results are shown in Table 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com