Nickel-bismuth hybridized nanowire and preparation method thereof

A nanowire and hybridization technology, applied in the direction of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of demanding operability, complicated preparation process, low gas sensitivity, etc., and is suitable for large-scale industrial production , easy-to-implement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

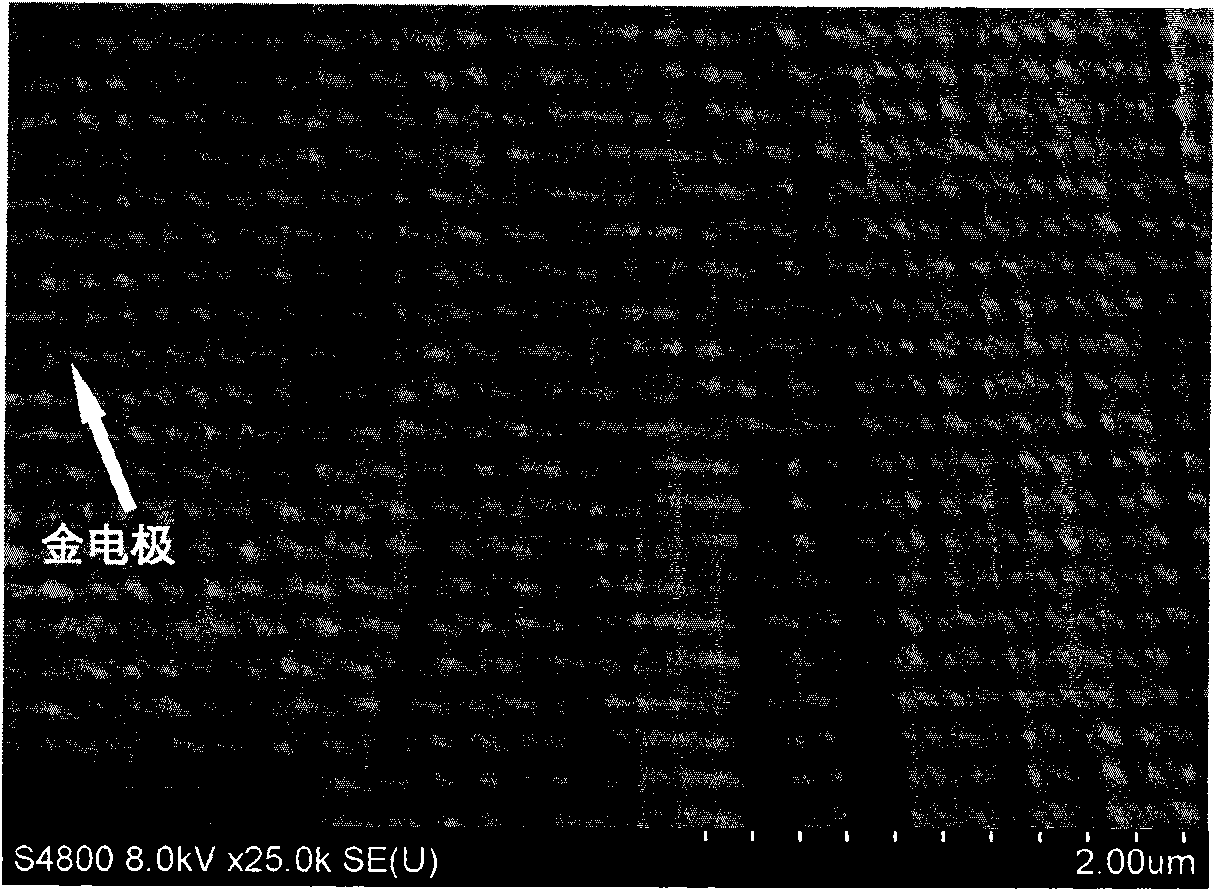

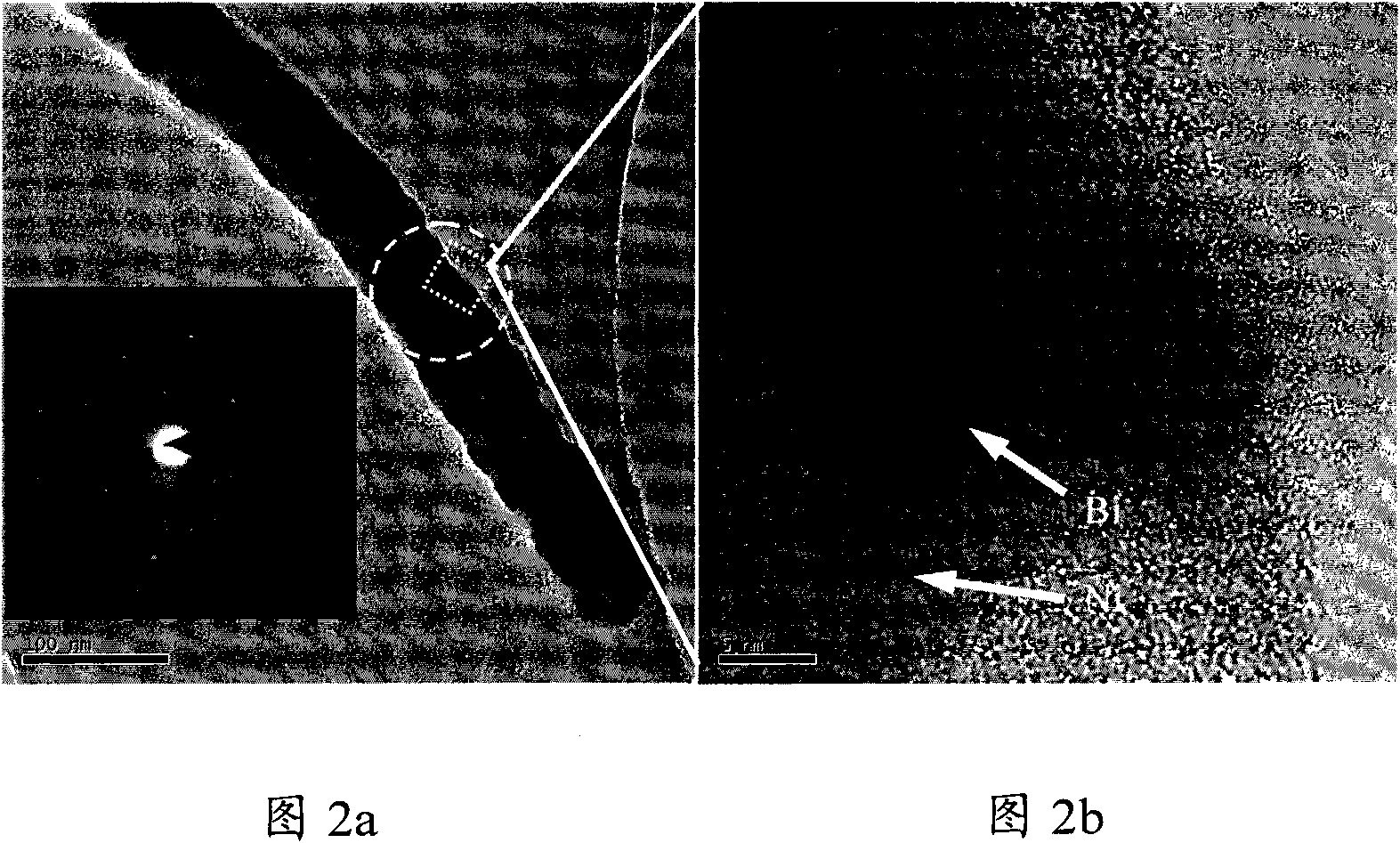

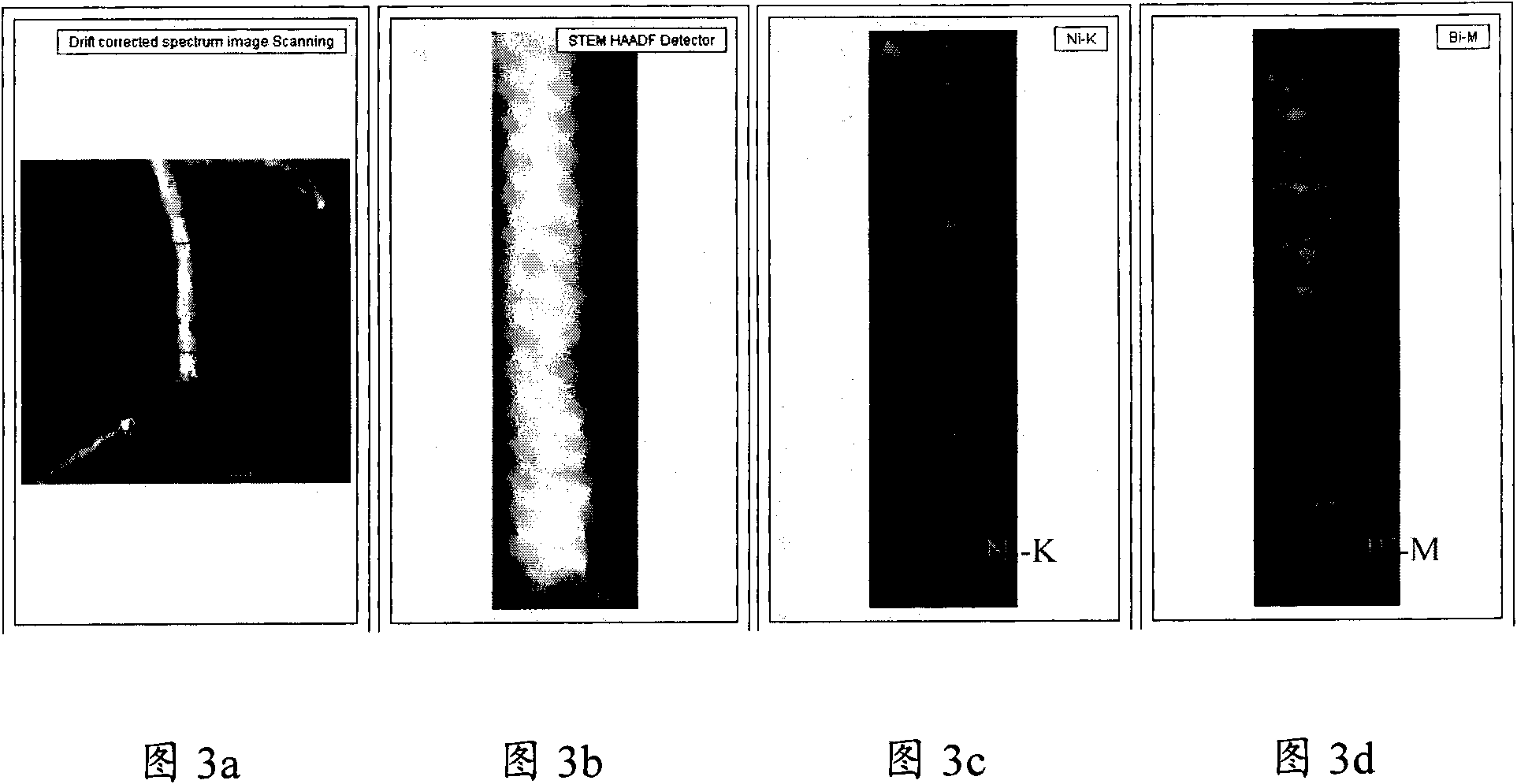

[0056] Preparation of nickel and bismuth hybrid nanowires:

[0057] 1) Anodize the aluminum sheet, first place the aluminum sheet in a sulfuric acid solution with a concentration of 0.3M, anodize for 12 hours at a DC voltage of 10V, and then soak the aluminum sheet in a mixed solution at a temperature of 50°C for 8 hour, obtain the aluminum flake after anodic oxidation for the first time; Described mixed solution is that 4wt% phosphoric acid and 1.6wt% chromic acid mix by concentration;

[0058] 2) Anodizing for the second time, repeating the anodizing process of step 1) for the aluminum sheet obtained in step 1), and carrying out anodizing for the second time on the aluminum sheet;

[0059] 3) the aluminum flake obtained after step 2) is oxidized, first remove the unoxidized aluminum on the back side with a supersaturated tin tetrachloride solution, and then use a phosphoric acid solution with a concentration of 3wt% to corrode the aluminum oxide barrier layer at the bottom o...

Embodiment 2

[0064] Preparation of Nickel and Bismuth Hybrid Nanowires

[0065] 1) Anodize the aluminum sheet, first place the aluminum sheet in an oxalic acid solution with a concentration of 0.3M, anodize for 6 hours at a DC voltage of 40V, and then soak the aluminum sheet in a mixed solution with a temperature of 55°C for 8 hour, obtain the aluminum sheet after anodic oxidation for the first time; Described mixed solution is that concentration is that 5wt% phosphoric acid and concentration are that 1.7wt% chromic acid mixes;

[0066] 2) Anodizing for the second time, repeating the anodizing process of step 1) for the aluminum sheet obtained in step 1), and carrying out anodizing for the second time on the aluminum sheet;

[0067] 3) The aluminum sheet obtained after step 2) is oxidized, first remove the unoxidized aluminum on the back side with a supersaturated tin tetrachloride solution, and then use a phosphoric acid solution with a concentration of 3.5 wt% to corrode the aluminum oxi...

Embodiment 3

[0072] Preparation of Nickel and Bismuth Hybrid Nanowires

[0073] 1) Aluminum sheet anodizing, first place the aluminum sheet in oxalic acid solution with a concentration of 0.3M, anodize for 4 hours at a DC voltage of 50V, and then soak the aluminum sheet in a mixed solution with a temperature of 60°C for 10 hour, obtain the aluminum sheet after anodic oxidation for the first time; Described mixed solution is that concentration is that 5.5wt% phosphoric acid and concentration are that 1.8wt% chromic acid mixes;

[0074] 2) Anodizing for the second time, repeating the anodizing process of step 1) for the aluminum sheet obtained in step 1), and carrying out anodizing for the second time on the aluminum sheet;

[0075] 3) With the aluminum sheet obtained after oxidation in step 2), first remove the unoxidized aluminum on the back side with a supersaturated tin tetrachloride solution, and then use a phosphoric acid solution with a concentration of 4.5 wt% to corrode the aluminum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Radial length | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com