Device for controlling clamping and jacking of traveling table

A technology of mobile workbench and control device, which is applied in the field of press parts, can solve the problems of long oil filling time, high price, slow jacking speed, etc. reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

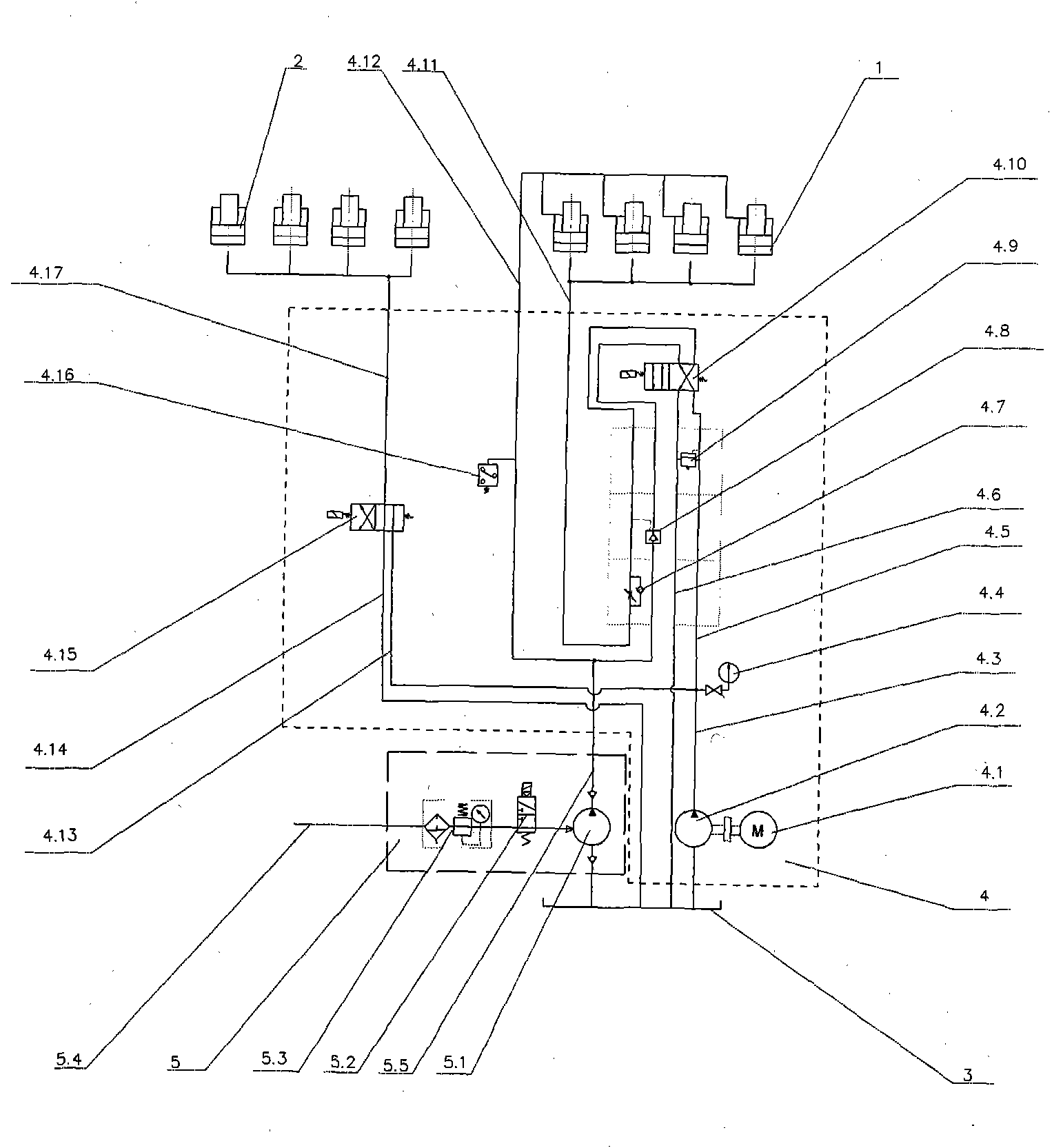

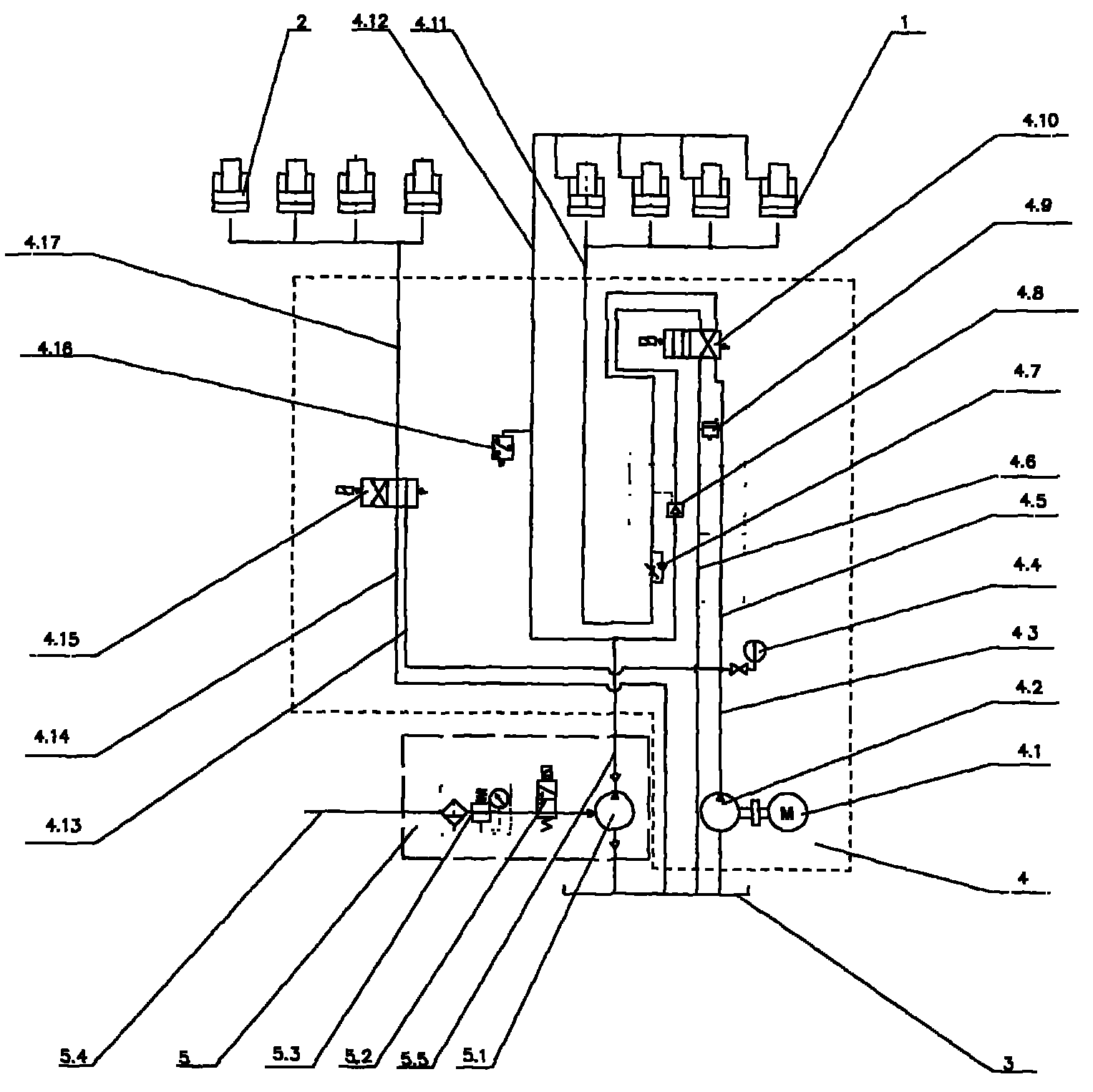

[0014] In the accompanying drawings, the clamping and jacking control device of the mobile workbench includes a clamping and releasing cylinder 1, a jacking cylinder 2, a fuel tank 3 and a power source for driving each cylinder, and the power source for driving each cylinder includes a pneumatic oil pump Unit 5 and electric oil pump unit 4.

[0015] The clamping and releasing cylinders 1 are four single-rod double-acting cylinders. The jacking cylinder 2 is four single-rod single-acting cylinders. The oil tank 3 is filled with anti-wear oil.

[0016] As shown in the drawings, the electric oil pump unit 4 includes an electric oil pump 4.2, which is an axial plunger pump driven by a motor 4.1 to pump out the oil in the oil tank 1. On the oil supply pipeline 4.3 of the electric oil pump 4.2, a second electromagnetic reversing valve 4.10 is connected via a connecting pipeline 4.5, and a first electromagnetic reversing valve 4.15 is connected through a connecting pipeline 4.13. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com