Pipe jacking device, construction device and construction method of subsurface tunnel

A technology for construction devices and jacking devices, which can be used in tunnels, earthwork drilling, mining equipment, etc., and can solve problems such as lack of stable excavation face

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

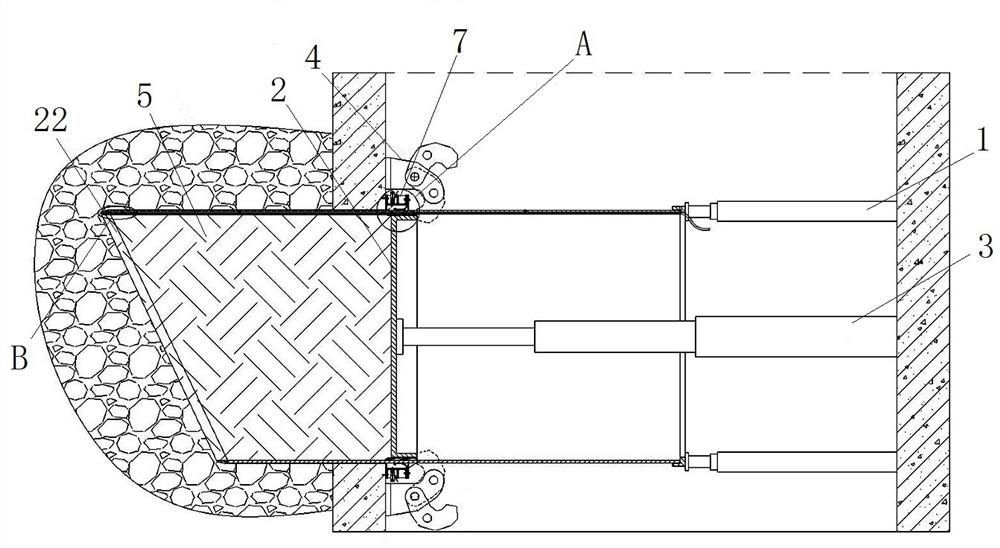

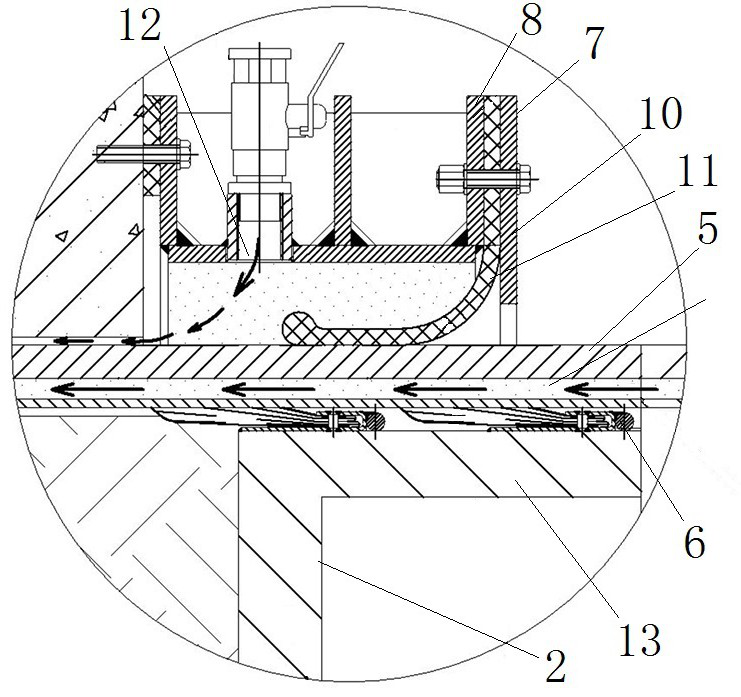

[0099] Such as figure 1 As shown, the construction device for underground excavation tunnel includes a pipe jacking device and a working pipe 5 arranged in the originating shaft. The working pipe 5 is located at the front end of the pipe jacking device. The pipe jacking device includes a pipe jacking device 1, 1 is a pipe jacking telescopic cylinder. In this embodiment, the pipe jacking telescopic cylinder is a pipe jacking hydraulic cylinder. The pipe jacking hydraulic cylinder can expand and contract in the front and rear directions. The end face is used to push and cooperate with the working pipe 5 to drive the working pipe 5 to push forward into the soil layer.

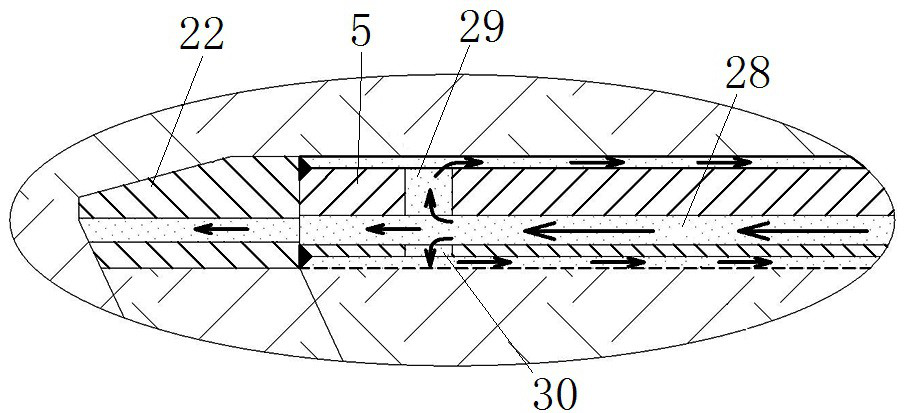

[0100] In this example, if figure 1 and image 3 As shown, there are multiple working tubes 5. During the tunnel excavation process, multiple working tubes 5 are pushed into the soil layer one by one, and are located at the angle between the front end face of the front end working tube 5 and the central axis of ...

specific Embodiment 2

[0115] The difference with specific embodiment 1 is:

[0116] Such as Figure 7 to Figure 9 As shown, in the construction device of the underground excavation tunnel, the front end of the front end working tube 5 is equipped with cutting teeth 23, and the cutting teeth 23 are evenly arranged in the circumferential direction of the front end working tube 5 in a fork structure, so as to improve the penetration of the working tube 5 into the soil layer. speed.

[0117] In the pipe jacking device of underground excavation tunnel, such as Figure 7 and Figure 8 As shown, it also includes a circumferential turning device 16, which is installed between the pipe jacking hydraulic cylinder and the working pipe 5, and the circumferential turning device 16 is used to push the working pipe 5 in the pipe jacking hydraulic cylinder. During the process, the working pipe 5 is pushed into the soil layer in a reciprocating manner in the circumferential direction.

[0118] Specifically, such ...

specific Embodiment 3

[0126] The difference from the specific embodiment 1 is that the circumferential rotation structure includes a rotary drive mechanism, and the rotary drive mechanism includes a motor and a meshing gear. The motors are arranged in pairs, and the paired two motors are respectively fixed on the radial sides of the working tube. The motors Fixed on the fixed top iron, the output shaft of the motor is provided with an output gear, and the outer peripheral surface of the hoop is provided with a rack meshed with the output gear. When the working pipe is pushed into the soil layer, the two motors act synchronously. The positive and negative rotation of the motor drives the working tube to perform reciprocating rotary motion in the circumferential direction. The difference from the construction process of the construction device for the underground excavation tunnel in the specific embodiment 1 is that in step (2), during the process of the working pipe moving forward relative to the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com