Water stop ring with integrated hinge rubber ring

A hinged rubber ring, an integrated technology, applied in pipeline laying and maintenance, pipes, pipes/pipe joints/fittings, etc., can solve problems such as unsatisfactory water-stop effect, deformation of water-stop rubber ring, and reduced work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

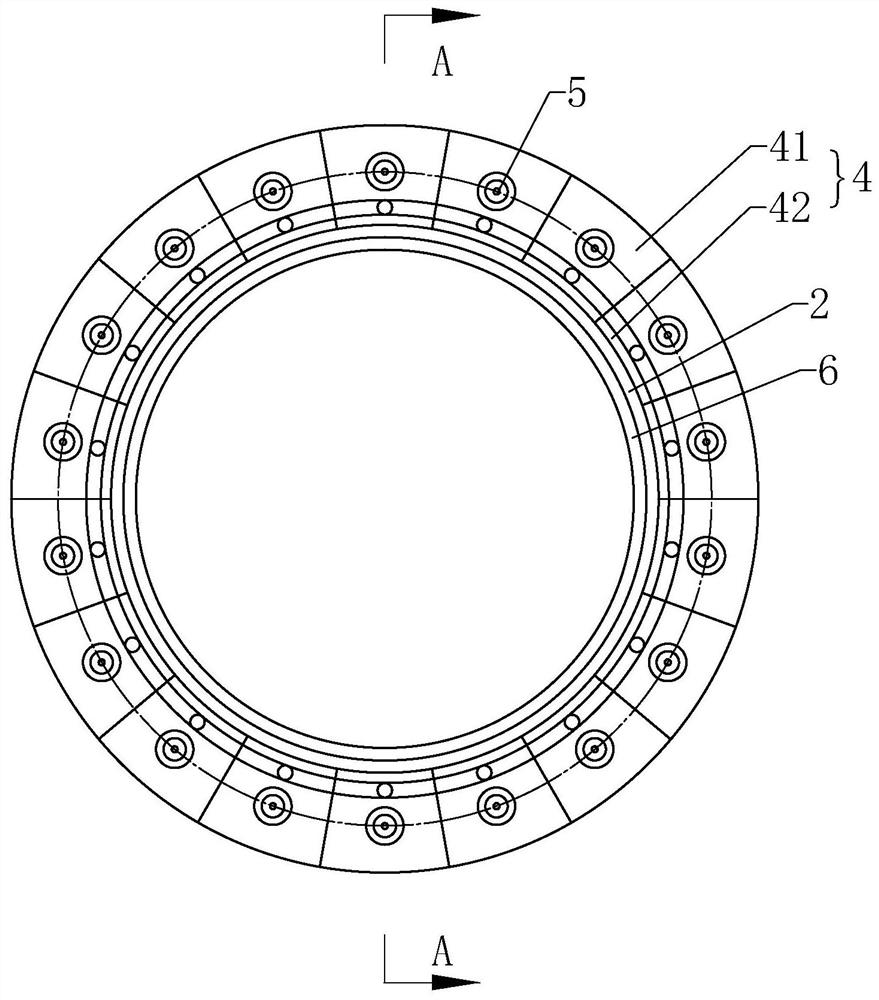

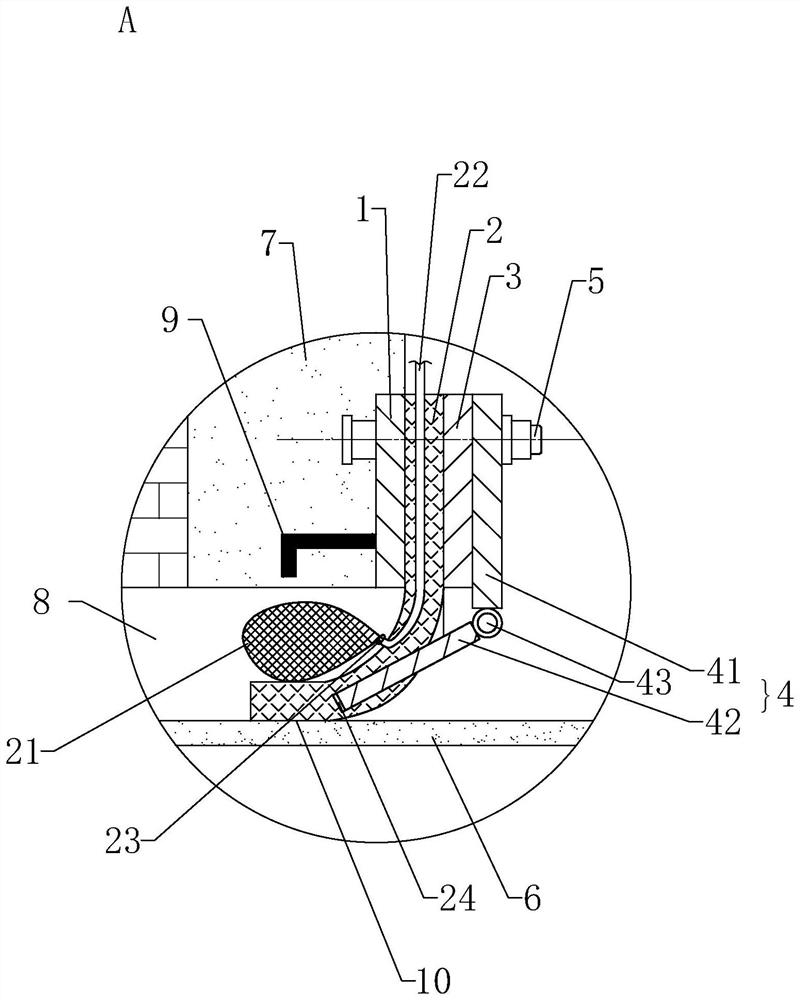

[0028] Embodiment 1 is a scheme in which the ventilation pipe and the rubber water stop ring are integrally formed:

[0029] First, install several pre-embedded bolts along the circumferential direction on the wall of the entrance to the hole, install the airbag on the vent pipe slidingly connected with the rubber water stop ring through at least one check valve, and then install the pre-embedded bolts in sequence through the pre-embedded bolts. The steel ring plate, the rubber water stop ring and the steel pressure ring are compressed by the compression nut.

[0030] as attached figure 2 to attach image 3 As shown in the figure, after the pipe jacking machine is pushed into the hole and the machine head passes through the steel pressure ring, the air filling device controls the inflation of the air bag installed between the inner wall of the well hole and the inner wall of the rubber water stop ring through the air pipe. The airbag is inflated, the airbag is controlled by...

Embodiment 2

[0032] Embodiment 2 is a scheme in which the ventilation pipe and the rubber water stop ring are slidably and fixedly connected:

[0033] First, install several pre-embedded bolts along the circumferential direction on the wall of the entrance hole, install the airbag on the vent pipe slidingly connected with the rubber water stop ring through at least one check valve, and then install the pre-embedded bolts in turn through the pre-embedded bolts. The steel ring plate, the rubber water stop ring and the steel pressure ring are compressed by the compression nut.

[0034] as attached figure 2 to attach image 3As shown in the figure, after the pipe jacking machine is pushed into the hole and the machine head passes through the steel pressure ring, the air filling device controls the inflation of the air bag installed between the inner wall of the well hole and the inner wall of the rubber water stop ring through the air pipe. The airbag is inflated, the airbag is controlled b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com