Pneumatic clamp for processing of claw pole outer surface

A technology of pneumatic clamps and claw poles, which is applied in the field of pneumatic clamps for external flat processing of claw poles, can solve the problems of high job assessment standards, high labor intensity, and easy edge jumping, so as to improve effective labor rate, shorten clamping time, and reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

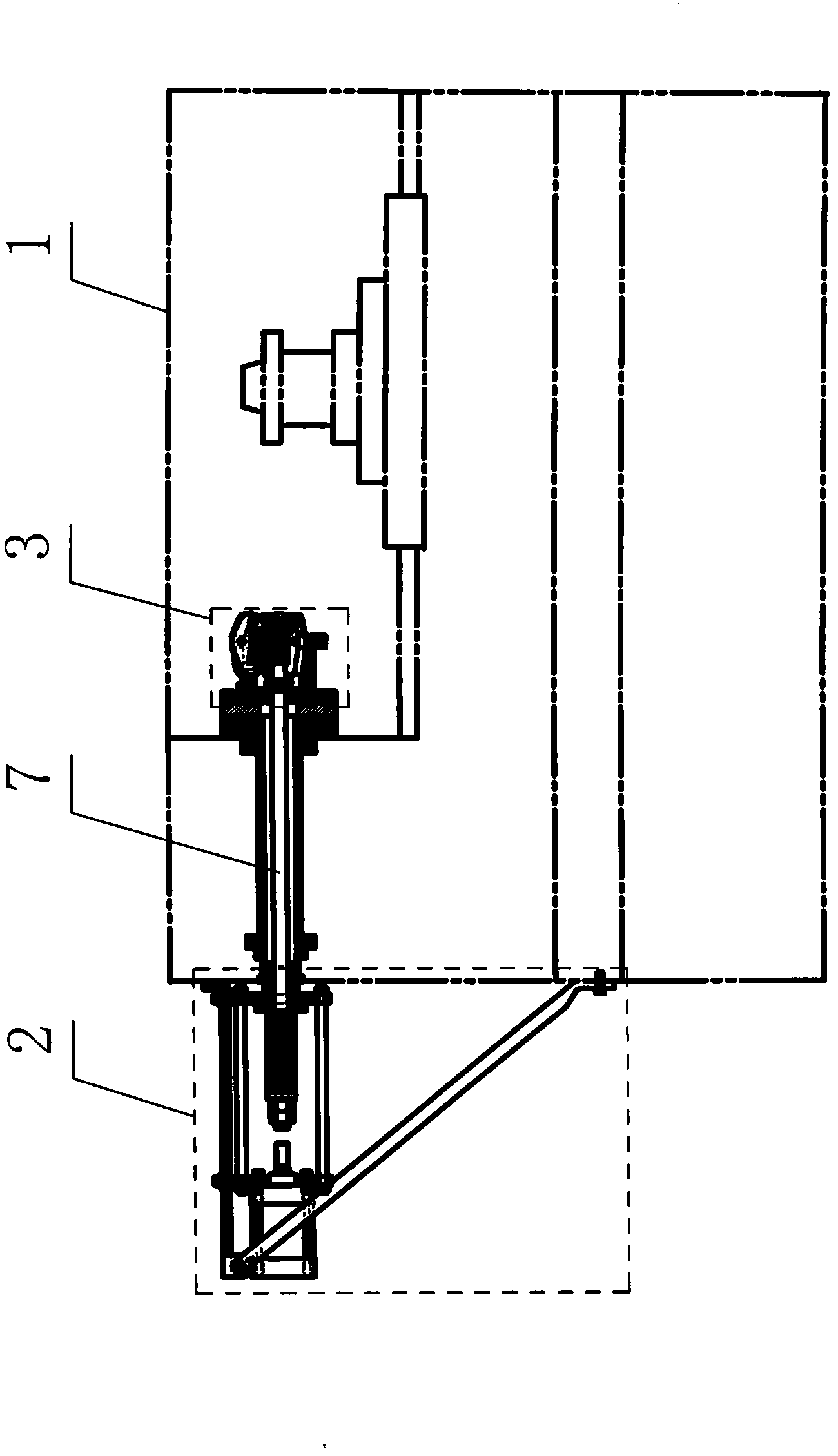

[0015] The pneumatic fixture for claw pole outer flat processing is composed of a pneumatic device 2 and a self-balancing three-jaw chuck 3. The jaw chuck 3 is connected by the pull rod 7 installed in the main shaft of the CNC lathe 1 to complete the processing action.

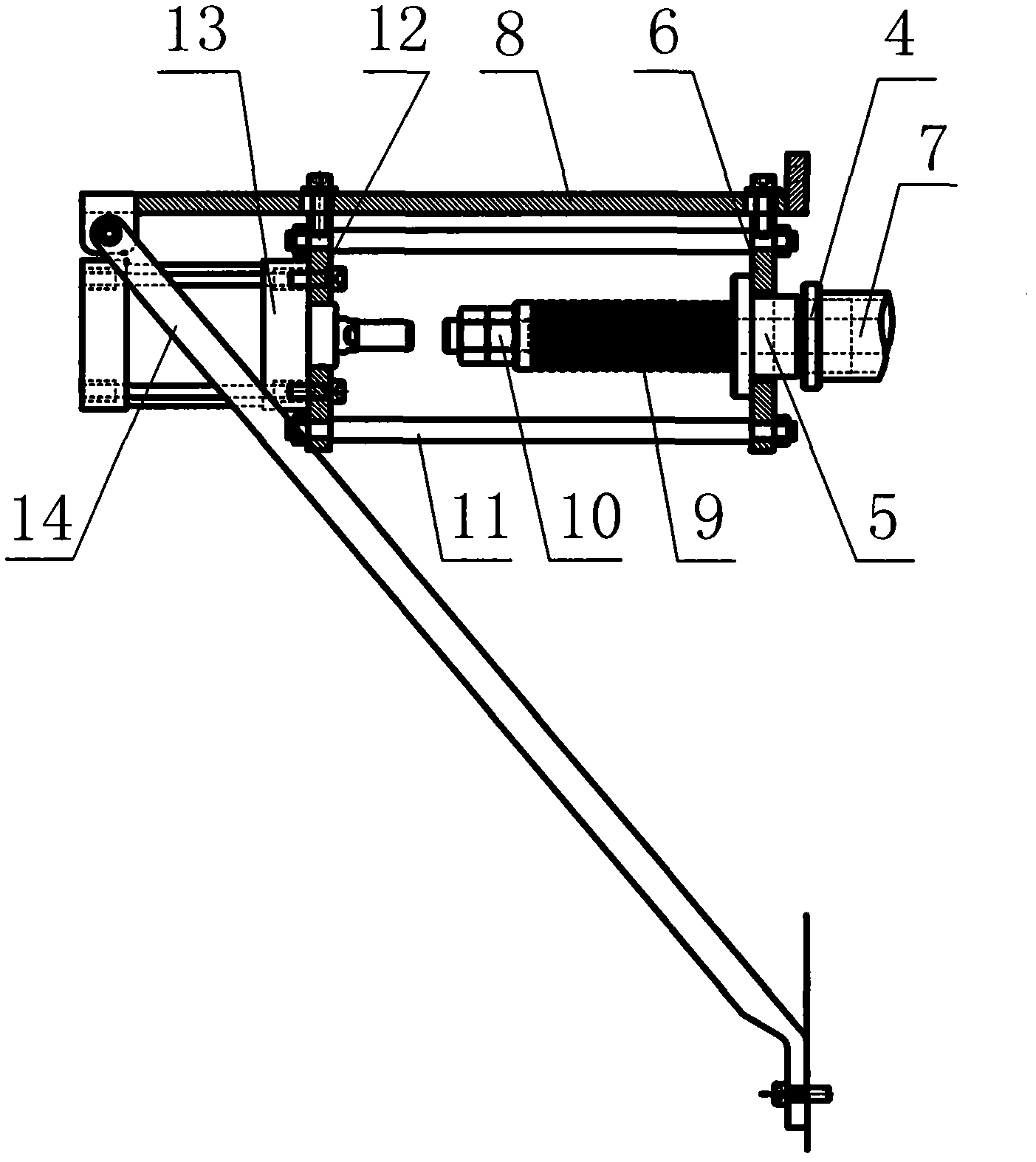

[0016] The pneumatic device 2 is composed of a locking round nut 4, a coupling head 5, a front pull plate 6, a pull rod 7, a horizontal plate 8, a disc spring 9, an adjusting nut 10, a connecting rod 11, a cylinder connecting plate 12, a cylinder 13 and Horizontal plate support bar 14 forms. The front pull plate 6 is fixed on the spindle of the CNC lathe 1 through the joint head 5 and the locking round nut 4, one end of the cross plate 8 is fixed on the upper part of the front pull plate 6 by screws, and the other end of the cross plate 8 is equipped with a cross plate Support rod 14, the middle part of horizontal plate 8 is fixedly equipped with cylinder connecting plate 12 by screw, and connecting rod 11 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com