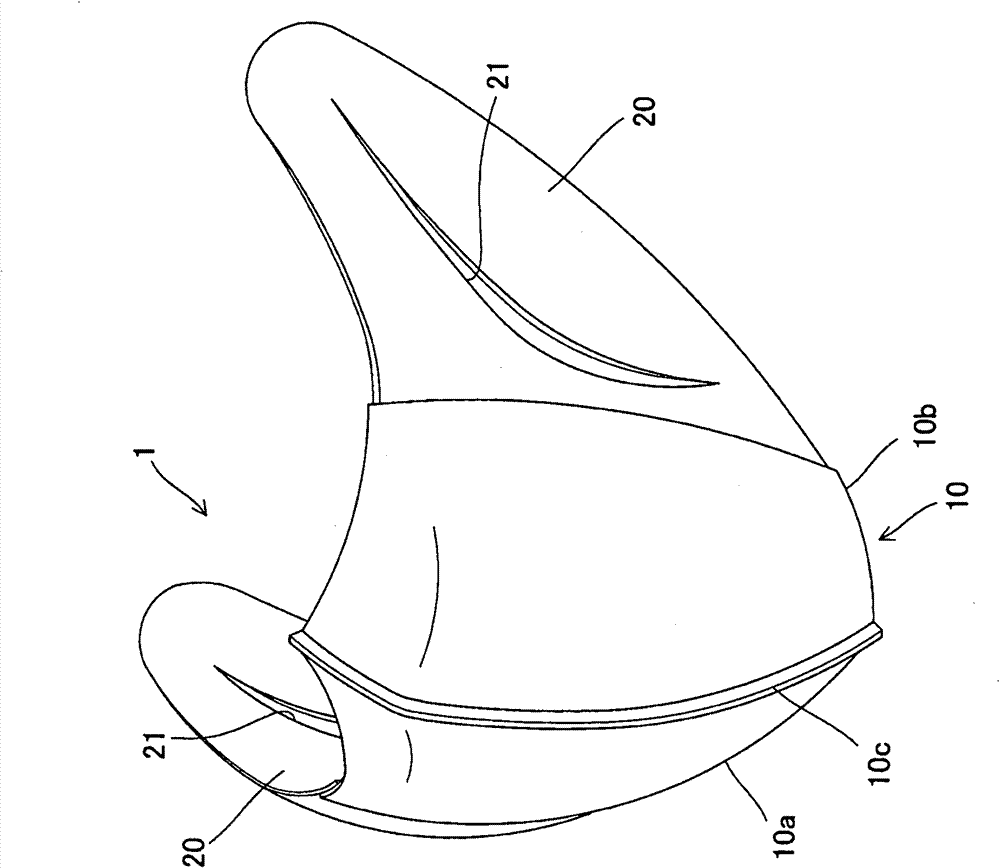

Mask

A mask and fiber sheet technology, applied in portable electrostatic devices, clothing, respiratory protection containers, etc., to achieve the effect of both air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

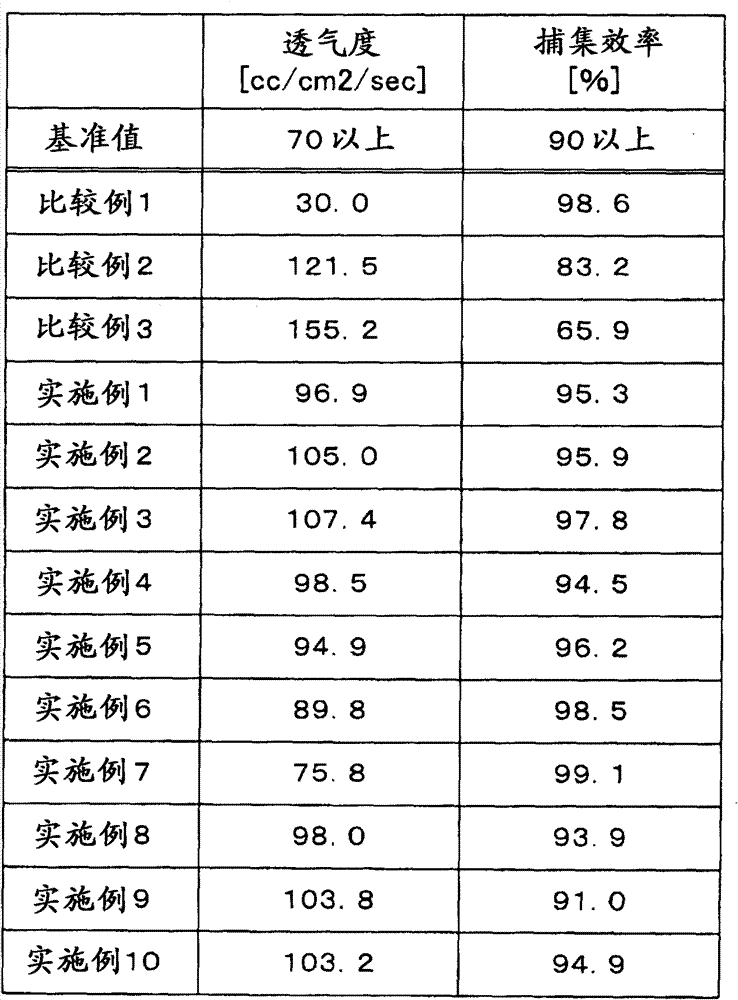

Examples

Embodiment 1

[0024] (evaluation sheet of Example 1)

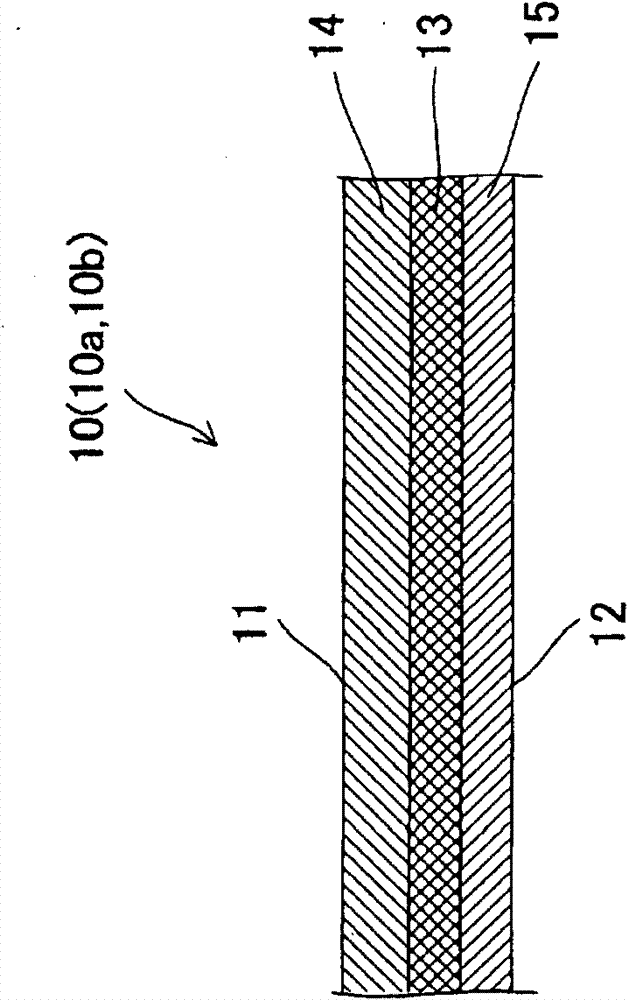

[0025] Regarding the evaluation sheet of Example 1, as the nonwoven fabric sheet corresponding to the first fiber sheet 13, a melt-blown nonwoven fabric sheet (average fiber diameter: 1.5 μm, weight per unit area: 2 g) made of electretized polypropylene was used. / m 2 ). In addition, as the nonwoven fabric sheet corresponding to the second fiber sheet 14, a spunbonded nonwoven fabric sheet made of electretized polypropylene (average fiber diameter: 17.6 μm, weight per unit area: 40 g / m 2 ). In addition, as the non-woven fabric sheet corresponding to the third fiber sheet 14, a point-bonded non-woven fabric sheet made of non-electretized polyethylene terephthalate / polyethylene (average fiber diameter: 17.6 μm, unit area Weight: 30g / m 2 ).

Embodiment 2

[0026] (evaluation sheet of Example 2)

[0027] Regarding the evaluation sheet of Example 2, as the nonwoven fabric sheet corresponding to the first fiber sheet 13, a melt-blown nonwoven fabric sheet made of electretized polypropylene (average fiber diameter: 1.5 μm, weight per unit area: 2 g / m 2 ). In addition, as the nonwoven fabric sheet corresponding to the second fiber sheet 14, a spunbonded nonwoven fabric sheet made of electretized polypropylene (average fiber diameter: 17.6 μm, weight per unit area: 30 g / m 2 ). In addition, as the non-woven fabric sheet corresponding to the third fiber sheet 14, a point-bonded non-woven fabric sheet made of non-electretized polyethylene terephthalate / polyethylene (average fiber diameter: 17.6 μm, unit area Weight: 30g / m 2 ).

Embodiment 3

[0028] (evaluation sheet of Example 3)

[0029] Regarding the evaluation sheet of Example 3, as the nonwoven fabric sheet corresponding to the first fiber sheet 13, a melt-blown nonwoven fabric sheet made of electretized polypropylene (average fiber diameter: 1.5 μm, weight per unit area: 2 g / m 2 ). In addition, as a nonwoven fabric sheet corresponding to the second fiber sheet 14, an air-through nonwoven fabric sheet made of electretized polyethylene terephthalate / polyethylene (average fiber diameter: 15.4 μm, weight per unit area: 30g / m 2 ). In addition, as the non-woven fabric sheet corresponding to the third fiber sheet 14, a point-bonded non-woven fabric sheet made of non-electretized polyethylene terephthalate / polyethylene (average fiber diameter: 17.6 μm, unit area Weight: 30g / m 2 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com