Qualitative and quantitative analysis method of elemental sulfur in light petroleum fractions and light petroleum products

A light oil, quantitative analysis technology, applied in the field of analytical chemistry, can solve the problems of low sensitivity and many interference factors, and achieve the effect of high precision, wide application and good accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Embodiment 1 Qualitative Analysis of Elemental Sulfur Structure in Light Petroleum Fractions and Light Petroleum Products

[0055] Gas chromatography conditions:

[0056] Chromatographic column: non-polar quartz capillary column, 30m×0.25mm,

[0057] Carrier gas: high purity helium,

[0058] Head pressure: 110-150kPa,

[0059] Injection port temperature: 210-250°C,

[0060] Column temperature: the initial temperature is 35-50°C, the temperature is raised to 180°C at 20-30°C / min, the temperature is raised to 250°C at 7-10°C / min, and the temperature is raised to 270-300°C at 20-30°C / min.

[0061] Injection volume: 0.5-0.9μL.

[0062] Mass Spectrometry Conditions:

[0063] Interface temperature: 230-250°C,

[0064] Ionization method: electron ionization (EI),

[0065] Electron energy: 70eV,

[0066] Detector voltage: 1.9-2.2kV.

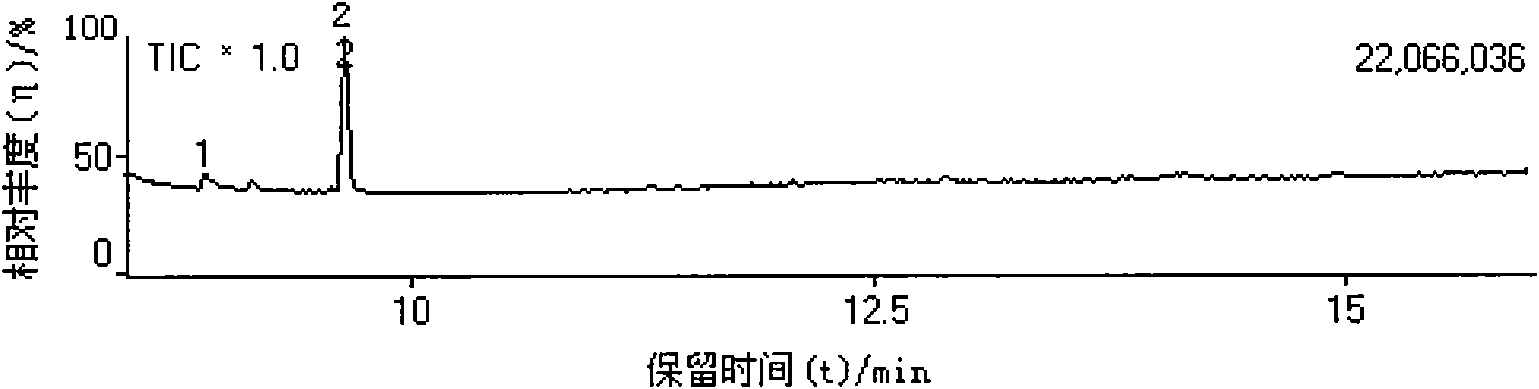

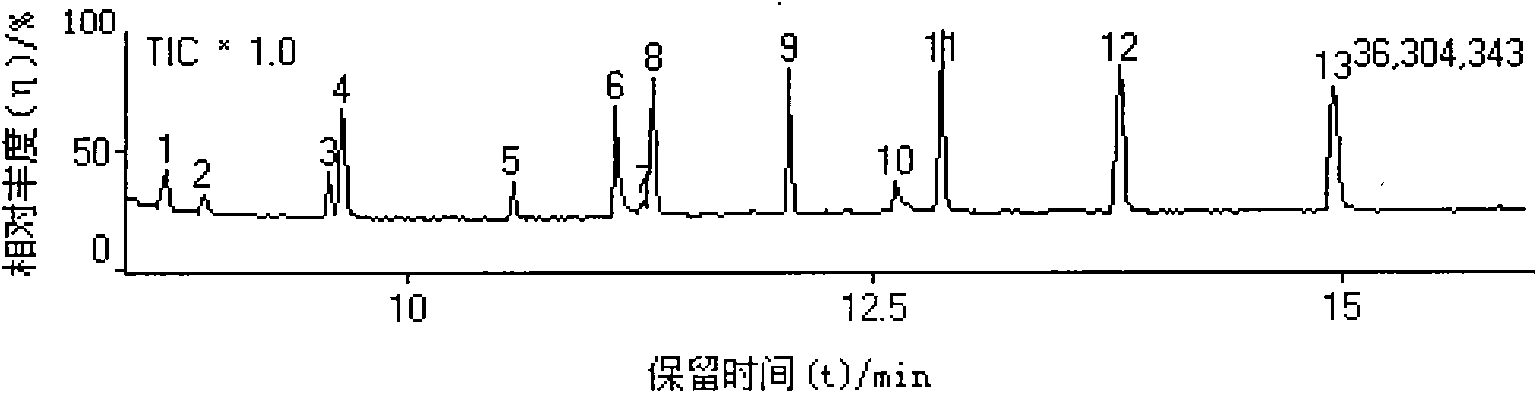

[0067] For straight-run gasoline, straight-run kerosene, straight-run light diesel oil, catalytically cracked gasoline, hydrogenated nap...

Embodiment 2

[0069] Embodiment 2 determines the change of elemental sulfur structure under analytical conditions

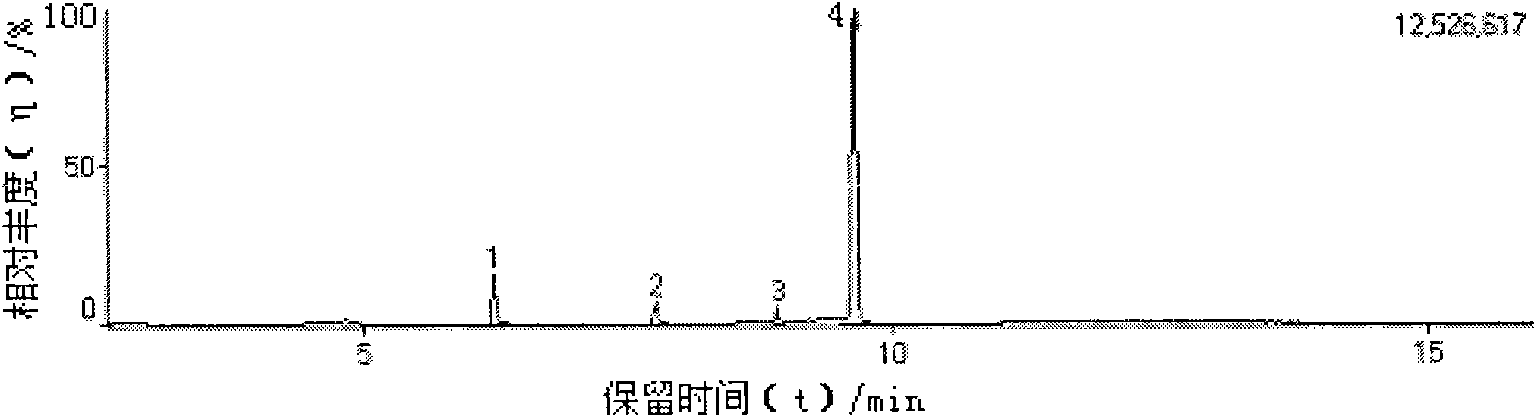

[0070] Using analytically pure carbon disulfide as a solvent to prepare elemental sulfur S 8 Standard solution, S 8 The concentration is 16.86mg / L. SIM analysis is carried out under the same conditions as in Example 1 and the injection port is 220°C. The solvent cutting time: 3.0min, the signal acquisition time: 3.0min, and the monitored ions are m / z 64, 96, 128, 160, 192, 224, 256, namely S 2 + , S 3 + , S 4 + , S 5 + , S 6 + , S 7 + , S 8 + . image 3 for the S 8 Standard solution analysis total ion chromatogram, from the mass spectrum analysis of No. 1, 2, 3 and 4 peaks in the figure, it can be known that No. 1, 2 and 4 peaks are 6 , S 7 , S 8 , No. 3 peak is the component in the carbon disulfide solvent.

[0071] For different concentrations of S 8 The standard solution was analyzed, and the peak area was used for quantification. The analysis results a...

Embodiment 3

[0079] The establishment of embodiment 3 standard curve

[0080] 0.0100g high-purity elemental sulfur S 8 The powder was dissolved in 100mL of analytically pure toluene solution to prepare an elemental sulfur standard solution with a mass concentration of elemental sulfur of 100mg / L. This solution is diluted respectively to the elemental sulfur standard solution of 0.005, 0.05, 0.10, 0.40, 0.70, 1.00, 5.00, 10.00, 15.00, 20.00, 25.00mg / L, carries out SIM under the chromatographic and mass spectrometric conditions identical with embodiment 1 For quantitative analysis, the monitored ions are m / z 64, 96, 128, 160, 192, 224, and 256. When the elemental sulfur concentration is less than 1.00mg / L, the quantitative ion selection is m / z 64; when the elemental sulfur concentration is greater than 1.00mg / L, the quantitative ion selection is m / z 128. Each diluted standard solution was measured 3 times and the average value was taken. The linear regression of the least square method is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com