Method for quantitative analysis of manganese in gasoline by using gas chromatography/mass spectrometry

A gas chromatography and quantitative analysis technology, applied in the field of quantitative analysis of manganese in gasoline, can solve the problems of troublesome handling, hazards to operators, and insufficient sensitivity, and achieve the effect of simple method and less sample consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Qualitative analysis of components in the MMT auxiliary agent in the production site of embodiment 1

[0072] Gas chromatography conditions:

[0073] Chromatographic column: non-polar quartz capillary column, 30m×0.25mm,

[0074] Carrier gas: high purity helium,

[0075] Head pressure: 90kPa,

[0076] Injection port temperature: 250°C,

[0077] Column temperature: the initial temperature is 100°C, the programmed temperature rise rate is 5°C / min, and the final temperature is 200°C.

[0078] Split ratio: 20:1.

[0079] Mass Spectrometry Conditions:

[0080] Interface temperature: 230°C,

[0081] Ionization method: electron ionization (EI),

[0082] Electron energy: 70eV,

[0083] Detector voltage: 1.5kV.

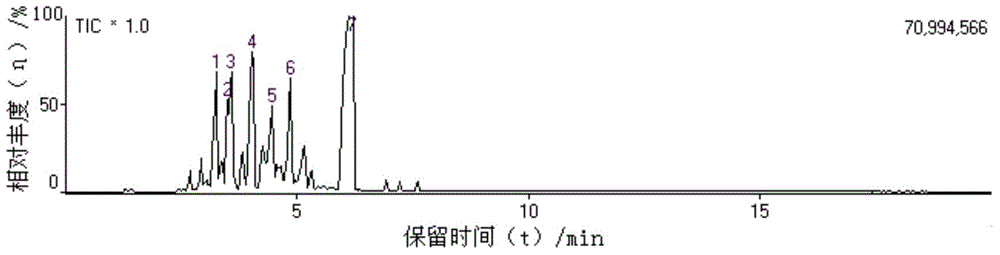

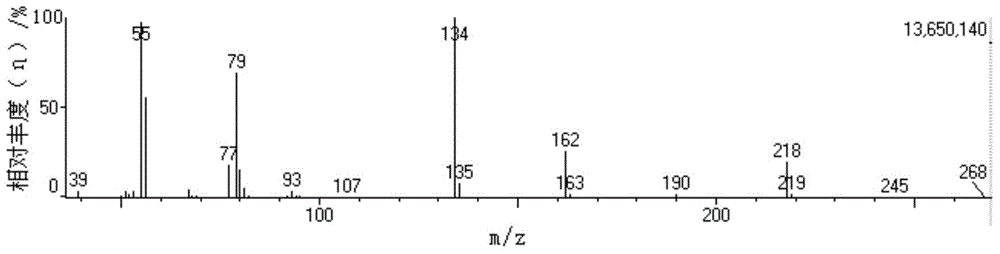

[0084] Under the above analysis conditions, scan (SCAN) analysis was carried out on the MMT additives used in the production site of Sinopec Jiujiang Branch. The total ion chromatogram (TIC) obtained from the analysis is shown in figure 1 , according to the a...

Embodiment 2

[0085] Embodiment 2 carries out quantification with dehydrated alcohol as MMT solvent

[0086] Gas chromatography conditions:

[0087] Chromatographic column: non-polar quartz capillary column, 30m×0.25mm,

[0088] Carrier gas: high purity helium,

[0089] Head pressure: 90kPa,

[0090] Injection port temperature: 230°C,

[0091] Column temperature: Initial temperature is 60°C, keep for 1min, raise temperature to 250°C at 25°C / min, keep for 6.4min,

[0092] Injection volume: 0.8μL,

[0093] Split ratio: 12:1

[0094] Mass Spectrometry Conditions:

[0095] Interface temperature: 230°C,

[0096] Ionization method: electron ionization (EI),

[0097] Electron energy: 70eV,

[0098] Detector voltage: 1.8kV.

[0099] Establishment of quantitative working curve for manganese in gasoline:

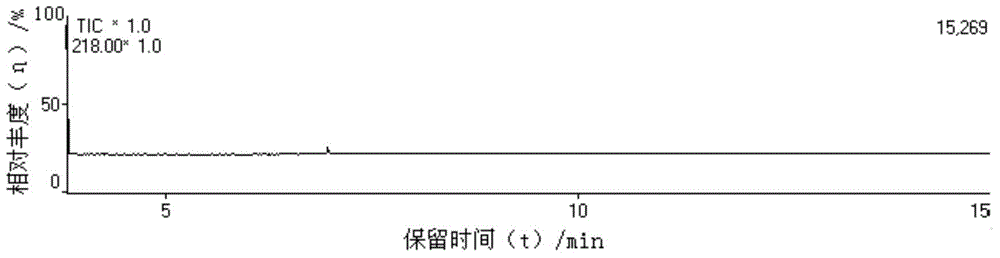

[0100] Under the analytical conditions determined above, the manganese contained in gasoline was quantified by the external standard method. Using the purchased high-purity MMT standard...

Embodiment 3

[0112] Embodiment 3 carries out quantification with catalytic cracking gasoline as MMT solvent

[0113] Gas chromatography conditions:

[0114] Chromatographic column: non-polar quartz capillary column, 30m×0.25mm,

[0115] Carrier gas: high purity helium,

[0116] Head pressure: 90kPa,

[0117] Injection port temperature: 230°C,

[0118] Column temperature: Initial temperature is 60°C, keep for 1min, raise temperature to 250°C at 25°C / min, keep for 6.4min,

[0119] Injection volume: 0.8μL,

[0120] Split ratio: 50:1

[0121] Mass Spectrometry Conditions:

[0122] Interface temperature: 230°C,

[0123] Ionization method: electron ionization (EI),

[0124] Electron energy: 70eV,

[0125] Detector voltage: 1.5kV.

[0126] Establishment of quantitative working curve for manganese in gasoline:

[0127] For oil refining production, the manganese content in gasoline is generally 1mg / L to 16mg / L. For the convenience of analysis, a quantitative working curve is established ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com