Method for making once-forming tissue chip and mold applied to same

A technology of tissue chips and molds, which is applied in the field of making one-time forming tissue chips and molds. It can solve the problems of complicated tissue chips, excessive wax melting, and high technical requirements, so as to improve production speed and quality, reduce displacement and chip loss rate, The effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

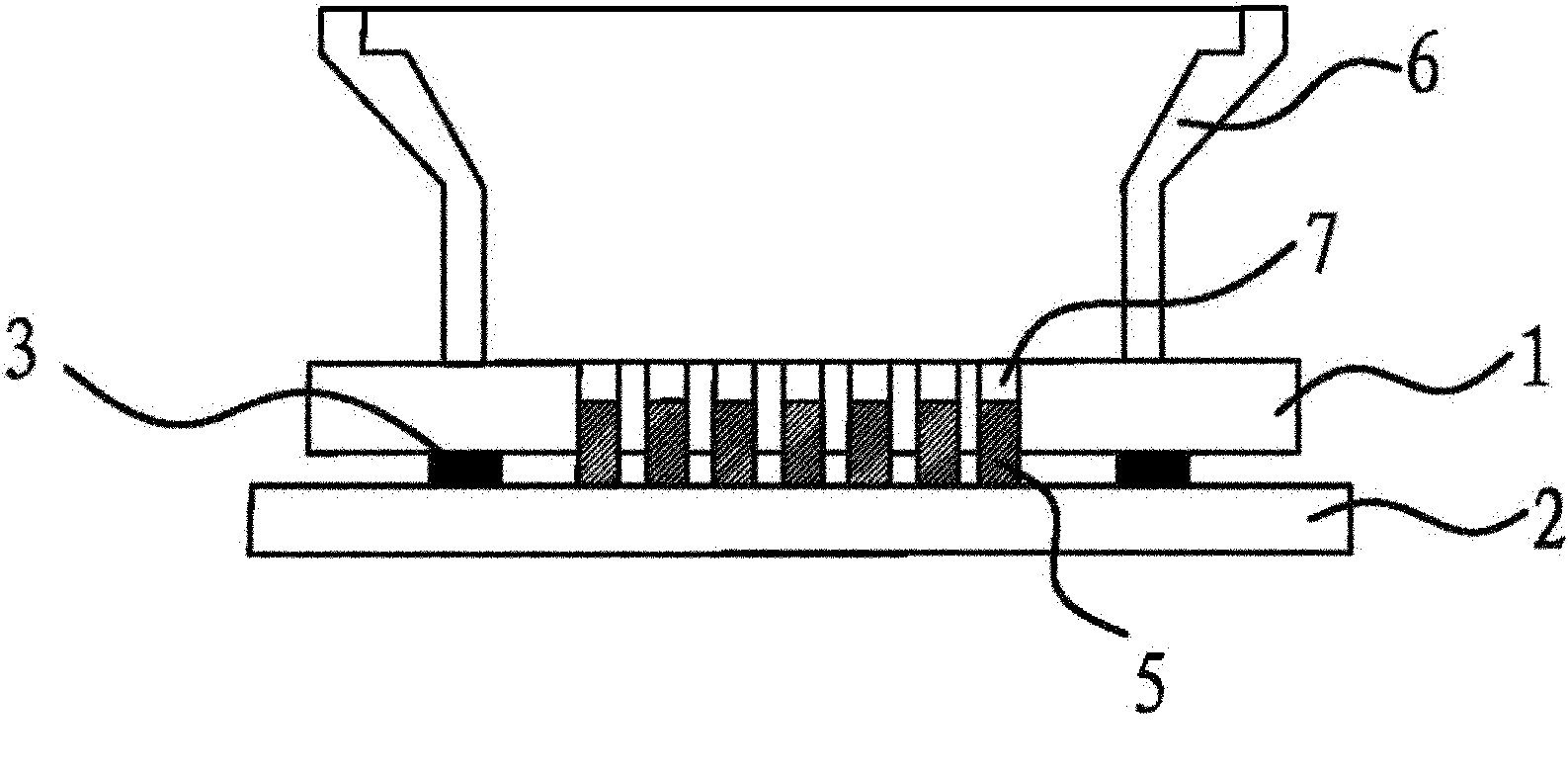

[0034]In the present invention, the mold for making a one-time forming tissue chip includes an array hole copper plate 1, an array needle copper plate 2 and two L-shaped copper spacers 3, and the array hole copper plate 1 is provided with n×n rectangular array through holes 4, and the array through hole The size and arrangement of 4 can be flexibly changed as required. One side of the array needle copper plate 2 is provided with an array needle 5 corresponding to the array through hole 4 one by one. The arrangement of the array needle 5 is exactly the same as that of the array through hole 4. The same as the depth, the array hole copper plate 1 and the array needle copper plate 2 are rectangular, and both have the same width, and the length of the array needle copper plate 2 is slightly longer than the length of the array hole copper plate 1, which is convenient for assembly and disassembly. Take the 6×7 array as an example to provide reference data: the number of array throug...

Embodiment 2

[0046] The content of embodiment 2 is basically the same as that of embodiment 1, the difference is that the mold uses two types of L-shaped copper pads 3, in addition to the 1mm thick copper pad in embodiment 1, there is also a 0.2mm thick copper pad piece. Since in Example 1, the operation of jacking up the tissue core needs to be carried out after the paraffin has solidified slightly, resulting in some tiny air bubbles remaining between the tissue core and the wax body in the jacked-up part, although the air bubbles do not affect the stability of the tissue core, nor affect the stability of the tissue core. Sectioning and staining, but it affects the beauty of the tissue microarray wax block. Therefore, different from Example 1 in the steps of preheating and wax injection, in this embodiment, the L-shaped copper spacer 3 with a thickness of 1 mm and the L-shaped copper spacer 3 with a thickness of 0.2 mm are prepared first, and after filling the tissue core Remove the 1mm ...

Embodiment 3

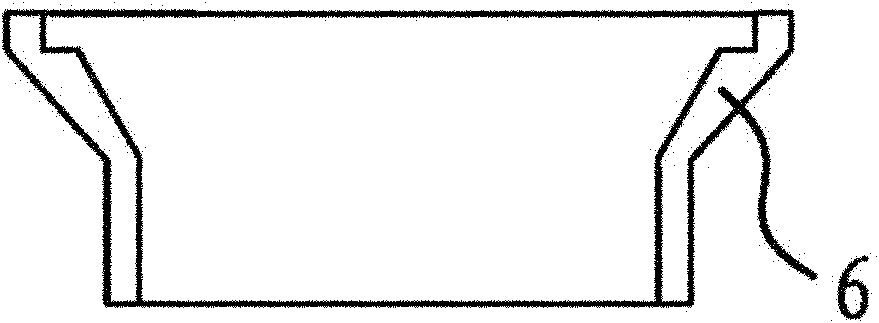

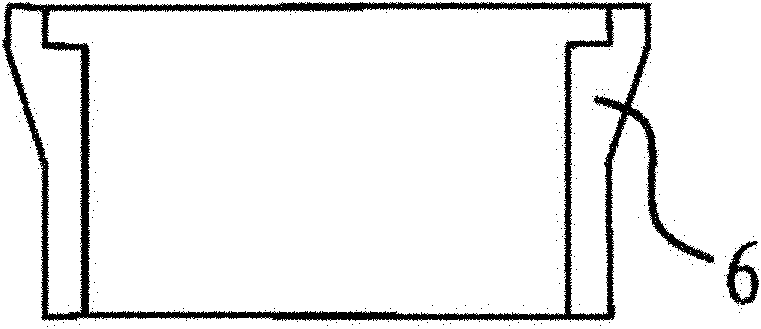

[0049] Embodiment 3 is basically the same as Embodiment 2, except that it is different from Embodiment 2 in the steps of preheating and wax injection. The 1mm thick L-shaped copper gasket 3 removed after filling the tissue core is replaced with a 0.2mm L-shaped copper pad 3. Copper spacer 3, push up the tissue core evenly, place the wax bearing tank 6 in the mold on the array hole copper plate 1, so that the array cavity 7 is located in the wax bearing tank 6, and then put the mold as a whole into the incubator for pre-heating. Heat until the wax column is slightly melted—the surface is shiny; take the mold out of the incubator, and immediately inject paraffin wax at 70°C, the amount injected should not exceed the supporting surface of the plastic embedding box, and wait for the paraffin wax in the wax holding tank 6 After the solidification is no longer transparent, put it into a plastic embedding box, and then fill it with 70°C paraffin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com