Direct-acting water pressure overflow valve with damping piston

A damping piston, direct-acting technology, which is applied in the direction of the valve's fluid energy absorption device, valve lift, valve details, etc., can solve the problems of increased processing difficulty, easy polarization of the valve, poor lubricity, etc., to improve reliability and use Effects of life, reduction of flow rate and noise, and improvement of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

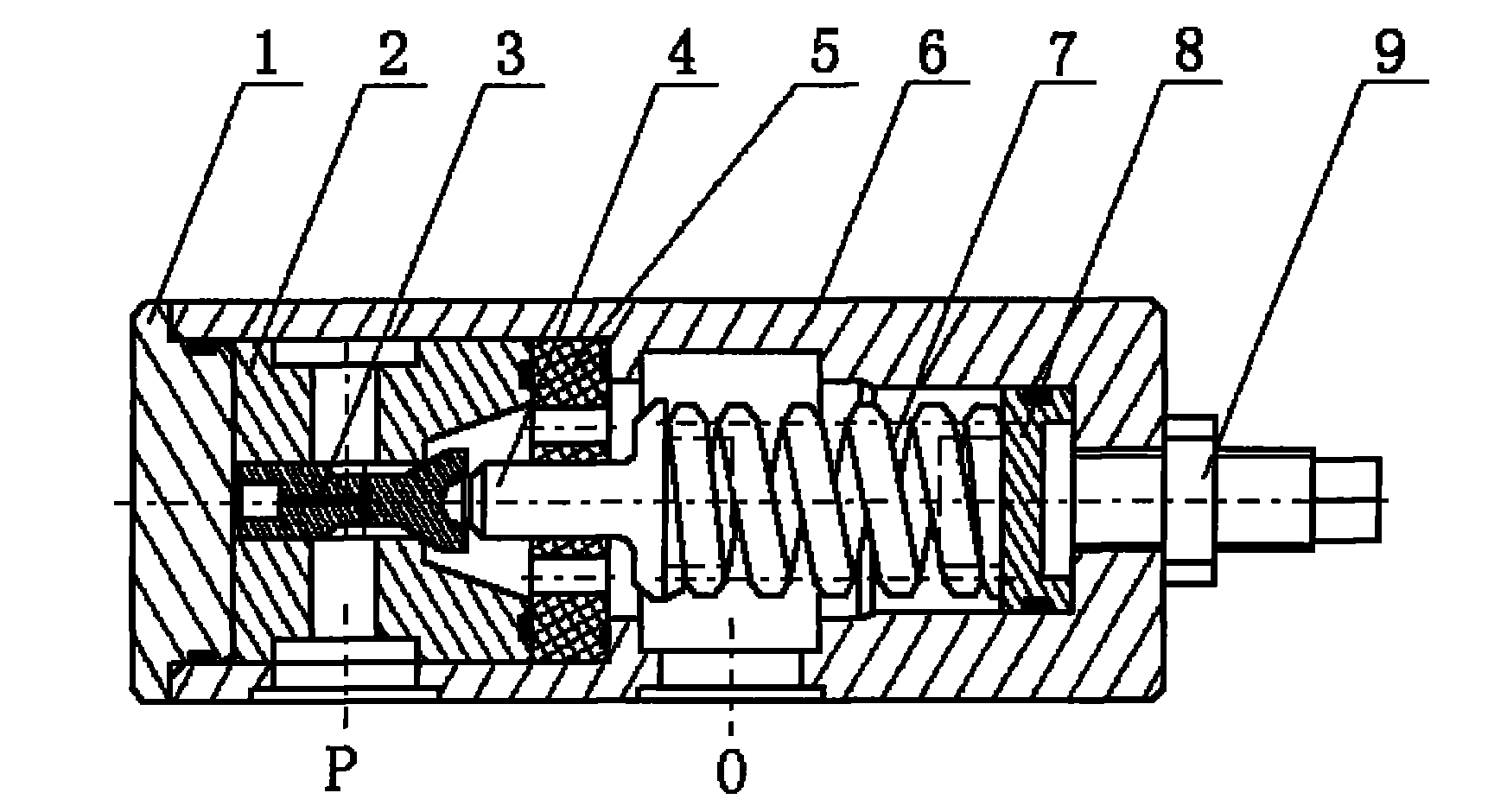

[0021] Such as figure 1 As shown, the overflow valve includes an end cover 1 and a valve seat 2, a valve core 3, a left spring seat 4, a guide sleeve 5, a spring 7, a right spring seat 8, and a pressure regulating screw 9 arranged sequentially in the valve body 6; The valve seat 2 has an annular groove in the radial direction, and a cross hole in the axial and radial direction, and a T-shaped elongated through hole in the valve core 3 in the axial and radial direction. The countersunk groove is connected, the countersunk groove and the end cover 1 form a damping chamber, the valve core 3 is inside the valve seat 2, and the cylindrical surface of its tail forms a guiding surface with the axial through hole of the valve seat 2, and the valve body formed by the valve seat 2 The mouth is a cone valve structure; the valve core 3 and the left spring seat 4 contact and cooperate to transmit the pressure regulating spring force, and the contact surface of the two is a spherical surfac...

Embodiment 2

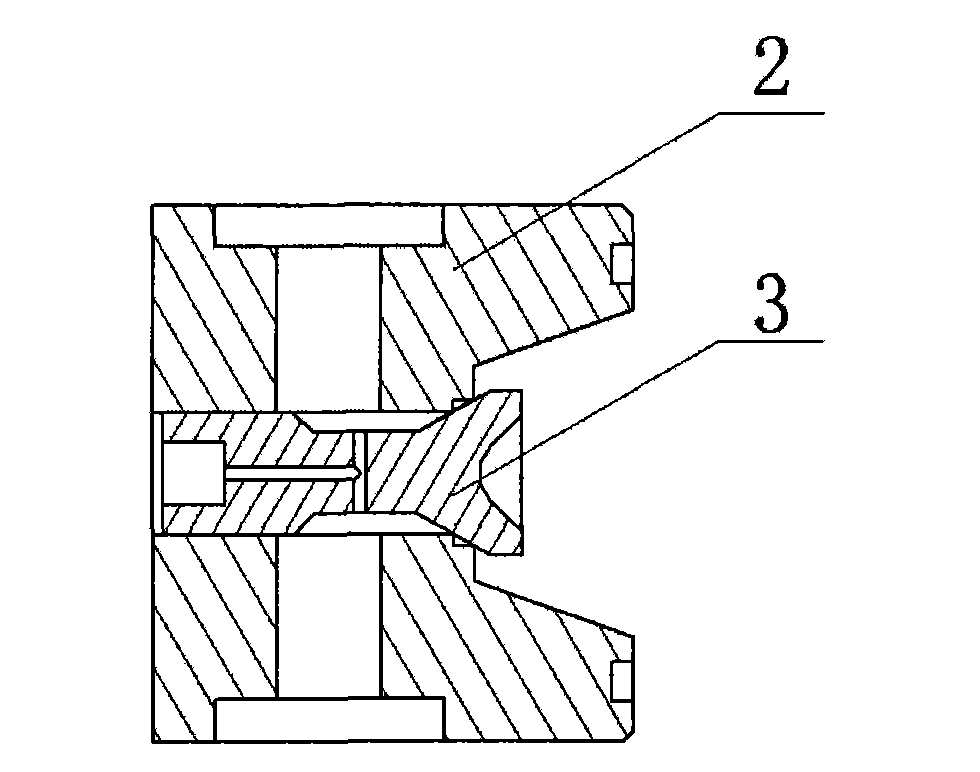

[0025] attached figure 2 It is the embodiment of the valve seat and the valve core secondary throttling valve port of the present invention. That is, when the relief valve works under a relatively high pressure state, the contact port between the valve seat 2 and the valve core 3 is designed as a countersunk groove and then the through hole is processed, so that a two-stage pressure is formed between the valve seat and the valve core. The structure of the orifice can reduce the hazards of cavitation and leakage.

Embodiment 3

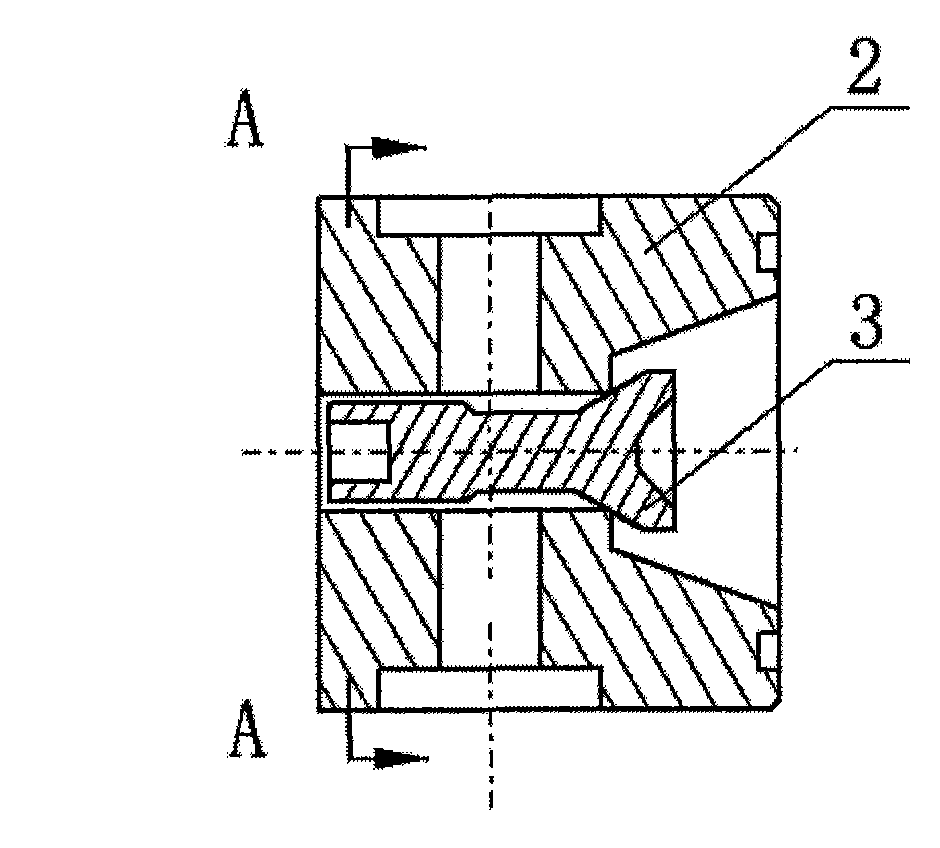

[0027] attached Figure 3-4 It is another embodiment in which the spool of the present invention acts as a damping piston. That is, there is no need to open T-shaped through holes along its radial and axial directions, and the outer cylindrical surface of the tail end of the valve core 3 is milled and flattened, so that the high-pressure water at the water inlet directly enters from here and acts on the bottom of the piston. On the one hand, it plays a damping role when the poppet valve is opened or closed, which is used to improve the stability of the poppet valve; on the other hand, it is used to ensure that the poppet valve will not tilt after opening, so as to improve the static characteristics of the poppet valve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com