Rubber material for preparing winding couplers and forming method for winding couplers

A technology of rubber materials and molding methods, which is applied in the direction of coating, etc., can solve the problems of expensive imported parts and cost pressures, and achieve the effects of improving international market competitiveness, ensuring adhesive performance, and improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

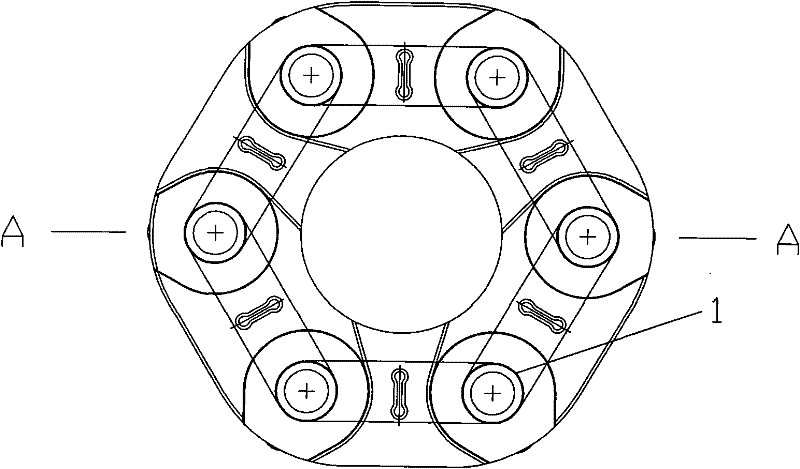

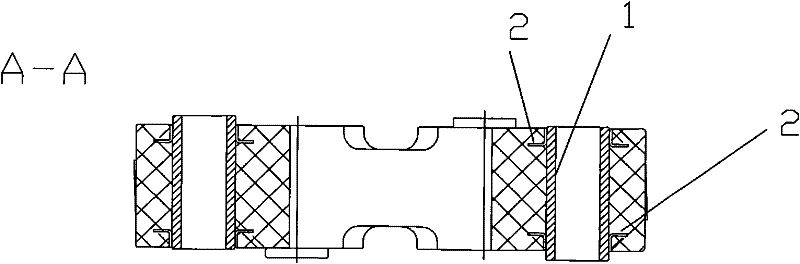

Image

Examples

Embodiment 1

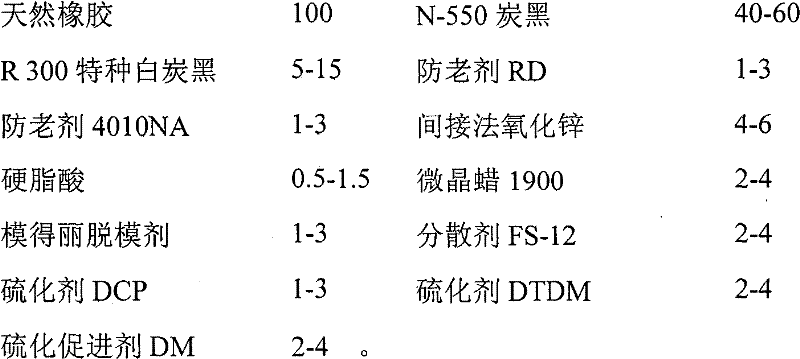

[0037] In this embodiment, the raw materials for preparing the rubber material of the wire-wound coupling consist of:

[0038] Natural rubber 100 N-550 carbon black 48

[0039] R-300 special white carbon black 10 anti-aging agent RD 2

[0040] Antiaging agent 4010NA 2 Indirect zinc oxide 5

[0041] Stearic acid 1 Moldex 2

[0042] Dispersant FS-12 3 Microcrystalline Wax 1900 3

[0043] Curing agent DCP 2 Curing agent DTDM 3

[0044] Vulcanization accelerator DM 3

[0045] In this embodiment, the forming method of the winding coupling is as follows:

[0046] a. Put the raw materials of the rubber material used for preparing the winding coupling into an internal mixer to obtain a mixed rubber material a, the mixing temperature is 110-120° C., and the mixing time is 8-10 minutes;

[0047] b. Put the rubber material a into the open mill and knead for 150-200 seconds to obtain the rubber material b, immerse the rubber material b in the RS620 release agent with a mass concentr...

Embodiment 2

[0057] In this embodiment, the raw materials for preparing the rubber material of the wire-wound coupling consist of:

[0058] Natural rubber 100 N-550 carbon black 40

[0059] R-300 special white carbon black 5 Antiaging agent RD 1

[0060] Antiaging agent 4010NA 1 Indirect zinc oxide 4

[0061] Stearic acid 0.5 Moldex 1

[0062] Dispersant FS-12 2 Microcrystalline Wax 1900 2

[0063] Curing agent DCP 1 Curing agent DTDM 2

[0064] Vulcanization accelerator DM 2

[0065] In this embodiment, the forming method of the wire-wound coupling is the same as that in Embodiment 1.

Embodiment 3

[0067] In this embodiment, the raw materials for preparing the rubber material of the wire-wound coupling consist of:

[0068] Natural Rubber 100 N-550 Carbon Black 60

[0069] R-300 special white carbon black 15 anti-aging agent RD 3

[0070] Antiaging agent 4010NA 3 Indirect zinc oxide 6

[0071] Stearic acid 1.5 Moldex 3

[0072] Dispersant FS-12 4 Microcrystalline Wax 1900 4

[0073] Curing agent DCP 3 Curing agent DTDM 4

[0074] Vulcanization accelerator DM 4

[0075] In this embodiment, the forming method of the wire-wound coupling is the same as that in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com